Quaternary positive electrode material and preparation method and application thereof

A cathode material and cathode technology, applied in the field of quaternary cathode materials and their preparation, can solve the problems of large contact area of electrolyte, larger specific surface area, severe side reactions, etc., and achieve a simple preparation method, short cycle and easy synthesis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to one aspect of the present invention, the present invention relates to a kind of preparation method of quaternary cathode material, comprising the following steps:

[0025] Mix the positive electrode substrate, soluble cobalt salt, precipitant, complexing agent and water, separate the liquid and solid of the mixed system, collect the solid phase, dry and calcinate;

[0026] The general chemical formula of the positive electrode substrate is LiNi x co y mn z Al (1-x-y-z) o 2 , wherein, 0.9≤x<1, 0<y<0.07, 0<z<0.03.

[0027] The present invention mixes soluble cobalt salt, precipitating agent, complexing agent, water and positive electrode substrate, washes and coats the positive electrode substrate, and uniformly coats a layer of cobalt compound on the surface of the positive electrode substrate, which can improve the material The conductivity can also play the role of a protective layer, reducing the occurrence of side reactions between the positive elec...

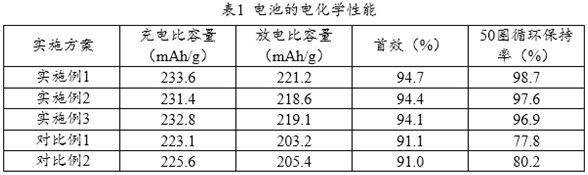

Embodiment 1

[0074] A preparation method of a quaternary cathode material, comprising the following steps:

[0075] (a) Dry-mix nickel-cobalt-manganese-aluminum hydroxide and LiOH in a mixer, calcinate the dry-mixed material in an ordinary box-type furnace at 700°C in an oxygen atmosphere for 8 hours, cool, pulverize and sieve to obtain Positive electrode substrate; wherein, the molar ratio of nickel-cobalt-manganese-aluminum hydroxide and LiOH is 1:1.025 (Li / Metal (Ni, Co, Mn and Al) = 1.025) in terms of metal elements; nickel-cobalt-manganese-aluminum hydroxide In the material, the molar ratio of Ni, Co, Mn and Al is 90: 7: 2: 1;

[0076] (b) Mix the positive electrode substrate, ammonia water, and distilled water obtained above at a mass ratio of 1:0.2:100, and stir at 200r / min for 5 minutes to obtain the first mixed system; then add the obtained first mixed system Add dropwise cobalt sulfate solution, the mass ratio of positive electrode base material and cobalt sulfate is 1:0.01, obt...

Embodiment 2

[0080] A preparation method of a quaternary cathode material, comprising the following steps:

[0081] (a) Dry-mix nickel-cobalt-manganese-aluminum hydroxide and LiOH in a mixer, calcinate the dry-mixed material in an ordinary box-type furnace at 700°C in an oxygen atmosphere for 8 hours, cool, pulverize and sieve to obtain Positive electrode substrate; wherein, the molar ratio of nickel-cobalt-manganese-aluminum hydroxide and LiOH is 1:1.025 (Li / Metal (Ni, Co, Mn and Al) = 1.025) in terms of metal elements; nickel-cobalt-manganese-aluminum hydroxide In the material, the molar ratio of Ni, Co, Mn and Al is 90: 7: 2: 1;

[0082] (b) Mix the positive electrode base material, ammonia water, and distilled water obtained above at a mass ratio of 1:0.15:100, and stir at 200r / min for 5 minutes to obtain the first mixed system; then add the obtained first mixed system Add dropwise cobalt sulfate solution, the mass ratio of positive electrode base material and cobalt sulfate is 1:0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com