Belt conveyor rubber belt surface dust cleaning device and installation method

A belt conveyor and cleaning device technology, applied in the direction of conveyors, cleaning devices, conveyor objects, etc., can solve the problems of unfavorable belt surface dust cleaning, waste of human resources, peeling of belt surface, etc., and achieve a good cleaning contact area , reduced labor input, and the effect of protecting the tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

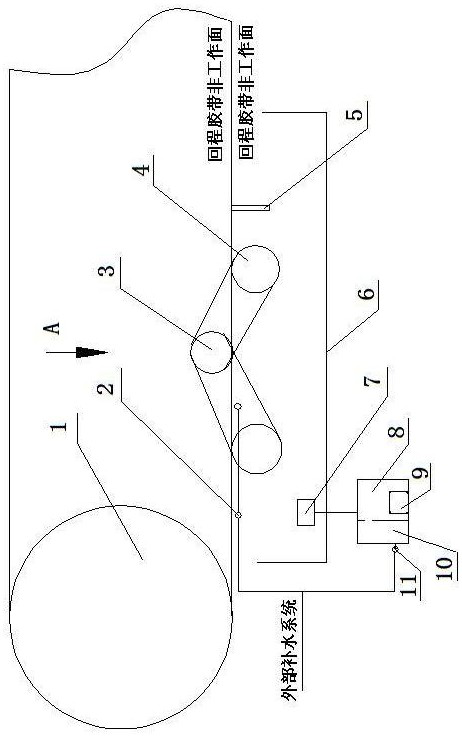

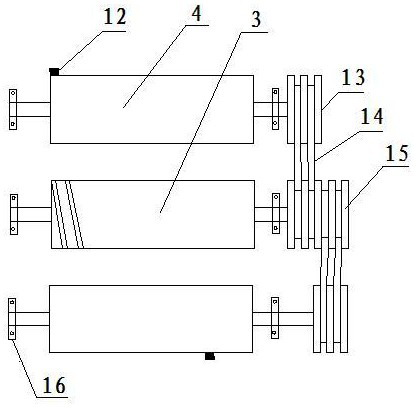

[0027] A belt conveyor belt surface dust cleaning device, which consists of: pressure roller 3, the pressure roller is installed on the non-working surface of the return belt, one end of the pressure roller is fixed with a transmission wheel II15, the transmission Wheel II is respectively connected with the transmission wheels I13 of two roller brush cleaners 4 through a triangular transmission belt 14. The outer surface of the roller brush cleaners is provided with bristles 12, and the bottom of the roller brush cleaners is equipped with a sump 6. An overflow port 7 is installed at the bottom of the sump, and the overflow port is connected to the distribution box through a pipeline, and the distribution box is divided into a water side box body 10 and a mud side box body 8 through a partition. The side of the water side box is connected to the clean water pump 11 through the pipeline, and the clean water pump is connected to the spray head 2 through the pipeline, and the spray...

Embodiment 2

[0029] According to the belt conveyor belt surface dust cleaning device described in embodiment 1, the pressure roller and the rolling brush cleaner are respectively connected to the bearing housing 16 on the frame, and the spray head is connected to the An external water replenishment system is installed on the pipeline between the clear water pumps, a mud cleaning port 9 is installed at the bottom of the mud side box, a plate cleaner 5 is installed behind the roller brush cleaner, and the belt drives the main drum 1 to drive Non-working surface movement of the return tape.

Embodiment 3

[0031] According to the installation method of the belt conveyor belt surface dust cleaning device described in embodiment 1 or 2, the method comprises the steps:

[0032] (1) Production and installation of pressure roller installed on the non-working surface of the return belt:

[0033]The pressure roller is made of ф219×10 carbon steel pipe. The surface of the pressure roller is lined with rubber or stripes. The thickness of the rubber lining is 10mm. The end cover is connected to the shaft, and the center alignment test is carried out. The shaft and the pressure roller are kept concentric; a set of PC210 bearing seats are installed on both sides of the shaft end. The V-belt 4-groove transmission wheel is installed. After the overall assembly of the pressure roller is completed, the bearing housings at the shaft end of the pressure roller are respectively installed on the side frame of the belt machine, and the tension between the pressure roller and the return belt is adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com