Dynamic preparation method of nascent-state nanometer layered manganese catalyst and application in enhanced oxidation filtration

A nano-layered, manganese catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult to meet the removal of various types of heavy metal pollution, poor removal of heavy metals, long aging cycle, etc. Achieve the effect of simple and easy construction process, considerable economic benefits and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

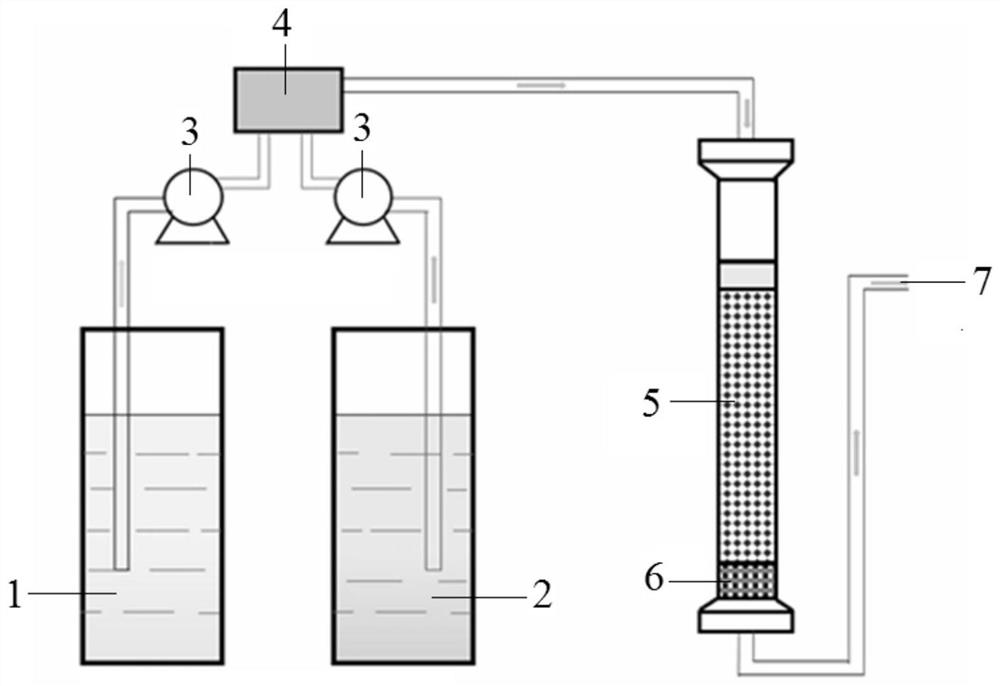

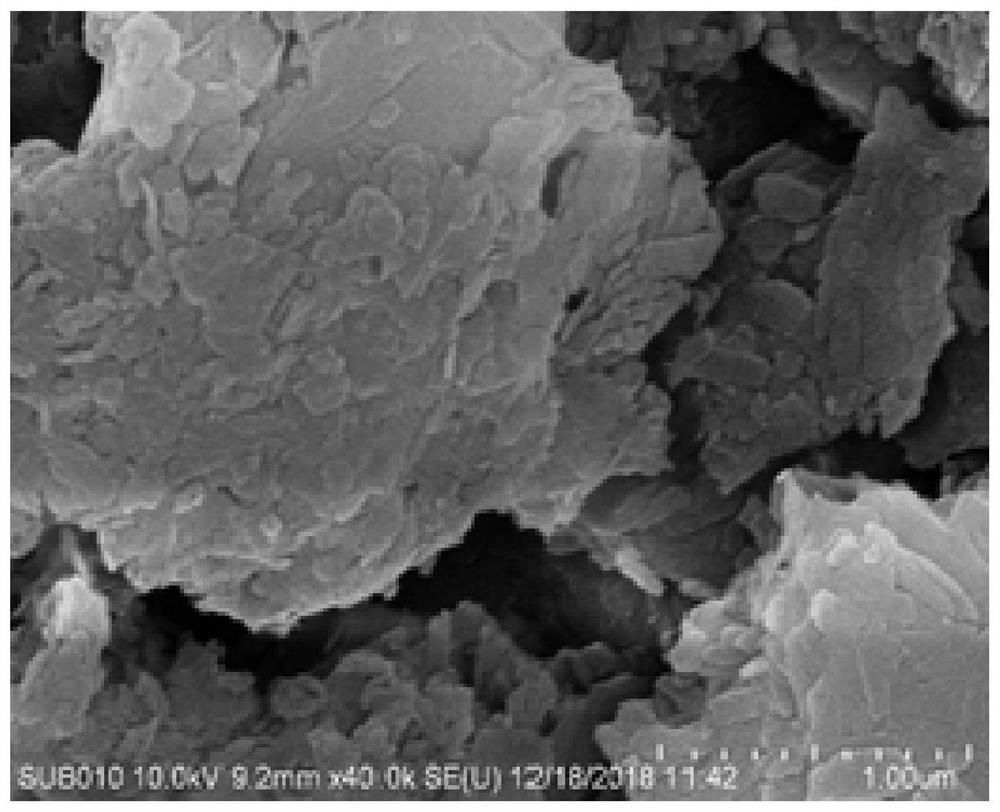

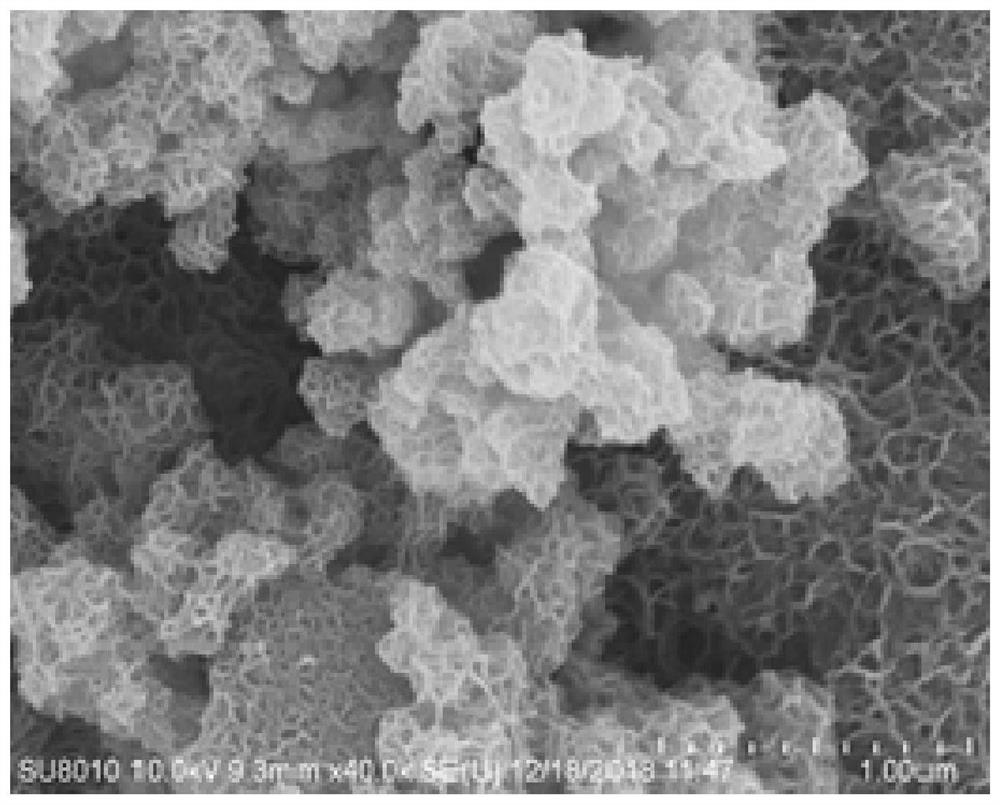

[0032] Specific embodiment one: the dynamic preparation method of a kind of new ecological nano-layered manganese catalyst in this embodiment is completed according to the following steps:

[0033] 1. Adsorption:

[0034] The porous zeolite particles were immersed in the divalent manganese solution under the condition of reciprocating vibration to adsorb Mn 2+ , after the adsorption is completed, the divalent manganese solution is discarded, and the adsorbed Mn 2+ zeolite particles;

[0035] 2. Preparation of manganese-loaded zeolite particles:

[0036] will be adsorbed with Mn 2+ The zeolite particles were immersed in the mixed solution of potassium permanganate and alkali for adsorption, rinsed after the adsorption was completed, and then dried naturally to obtain manganese-loaded zeolite particles;

[0037] 3. Construct manganese-loaded zeolite filter column, manganese-loaded zeolite filter tank or manganese-loaded zeolite filter pool:

[0038] Manganese-loaded zeolite...

specific Embodiment approach 2

[0046] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the particle diameter of the porous zeolite particles described in step one is 0.01mm~10mm, the porosity is 30%~75%, and the pore diameter is 0.3nm~1nm ; The speed of the reciprocating oscillation described in step 1 is 50 rpm to 500 rpm, and the amplitude is 10 mm to 30 mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the divalent manganese solution described in step one is one of manganese sulfate solution, manganese nitrate solution and manganese chloride solution or one of them Several mixed solutions; the concentration of the divalent manganese solution described in step 1 is 0.01mol / L-1mol / L; the adsorption time described in step 1 is 0.1h-72h. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com