A method for reducing the formation of residual adhesive in the process of cement-retained implant repair

An adhesive and retention technology, used in dental implants, dental prosthetics, medical science and other directions, can solve the problems of excessive overflow, reduce the precision of pre-bonding gaps, and complicated operation steps, and achieve improved precision and adhesive Residue reduction, effect of simplified steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings.

[0026] The present invention includes the following steps:

[0027] 1) The patient was placed on the healing abutment without temporary denture repair. After 2 weeks of healing, a machine-mixed polyether-silicone rubber closed-mouth impression was taken for a follow-up visit. The artificial gingiva was prepared and a super anhydrite model was irrigated.

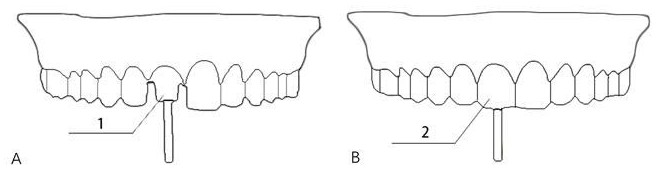

[0028] 2) Routinely scan the plaster model, import it into the CAD system, select the orientation of the implantation area and mark the edge line, design the personalized abutment 1 and the full crown restoration 2 in the implantation area and save, see figure 1 .

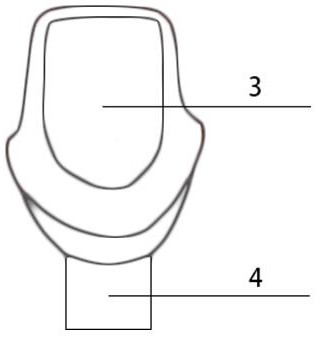

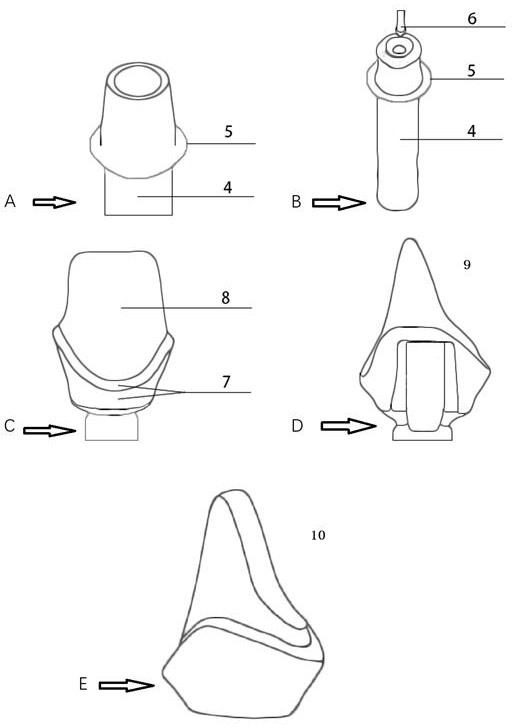

[0029] 3) Use the scanning cutting function to seal the screw channel of the personalized abutment part, simulating the clinical situation of closing the screw channel, and save the sealed personalized abutment 3 and implant substitute 4 separately, see f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com