Automatic welding system and welding process for gap bridge line of automobile ABS circuit board

An automatic welding and circuit board technology, applied in printed circuits, vibration suppression adjustment, printed circuit manufacturing, etc., can solve problems such as circuit board displacement, manual operation, affecting welding accuracy, etc., to prevent damage, easy operation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

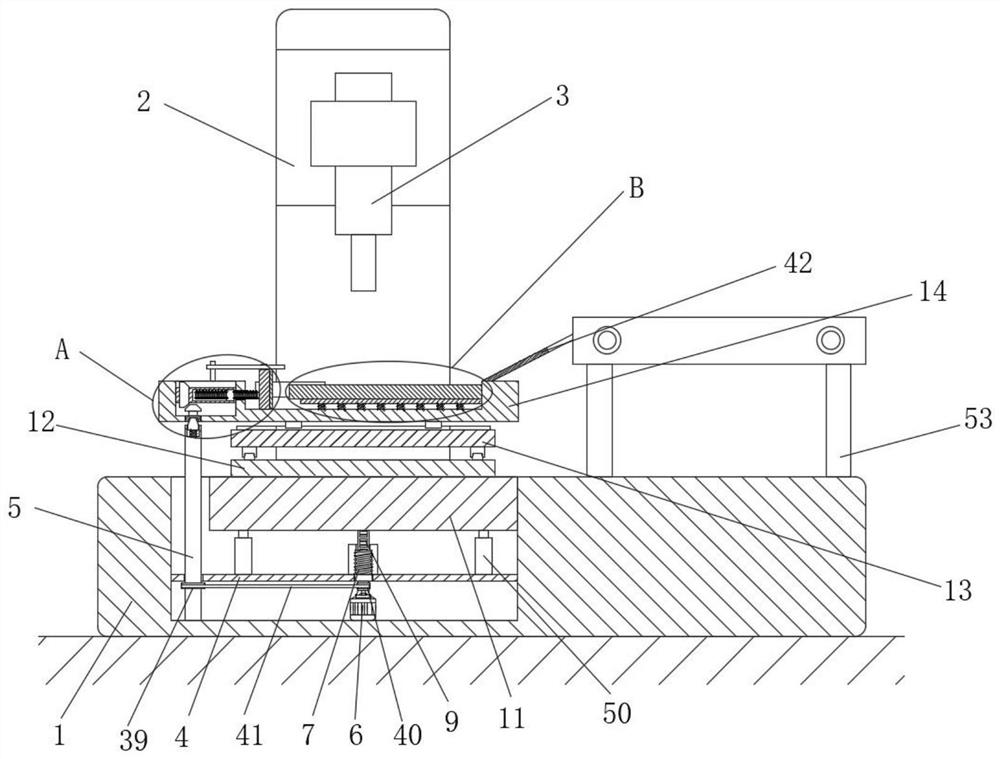

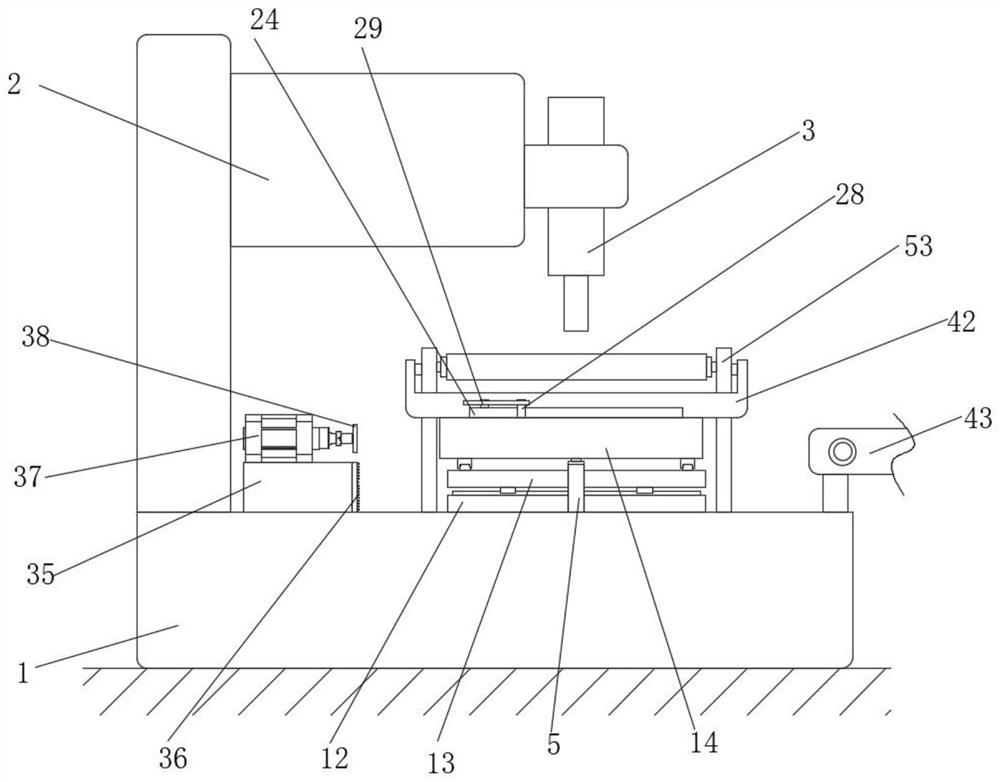

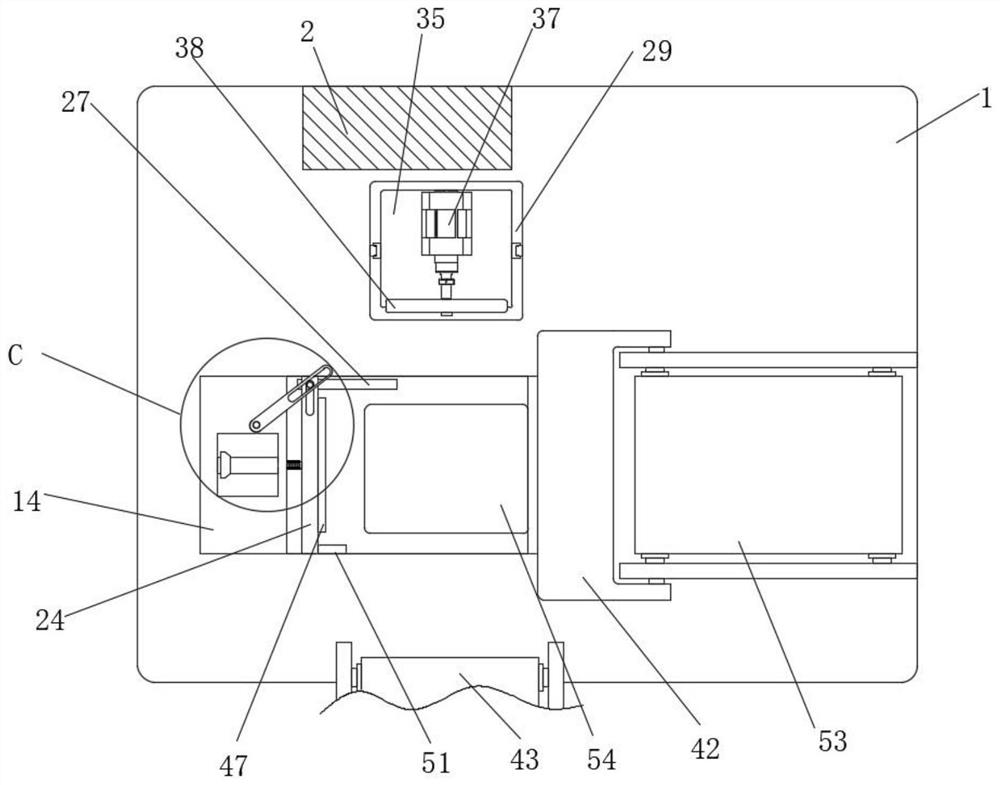

[0047] refer to Figure 1-13 , an automatic bridge line welding system for automotive ABS circuit boards, comprising a second stand 1, a support frame 2 is fixedly connected to one side of the top of the second stand 1, and an electric soldering iron 3 is fixedly connected to one side of the support frame 2 , the top of the second platform 1 is provided with a first support plate 12, the top of the first support plate 12 is slidably connected with a second support plate 13, and the inner walls of both sides of the second platform 1 are slidably connected with the same lifting platform 11, One side of the lifting platform 11 is fixedly connected with the first rack 34, and the second platform 1 is provided with a lifting assembly for lifting the lifting platform 11. To accommodate the assembly, the top of the second support plate 13 is slidably connected with a clamp 14, the top inner wall of the clamp 14 is placed with a circuit board 54, and the clamp 14 is provided with a fi...

Embodiment 2

[0062] Embodiment two: if Figure 14 As shown in -15, a bridge line automatic welding system for automobile ABS circuit boards, the difference between this embodiment and embodiment one is that: one side of the clamp 14 is slidably connected with a U-shaped plate 44, and the bottom of the U-shaped plate 44 is fixed A detector 45 is connected, and two symmetrical second hydraulic cylinders 46 are fixedly connected to one side of the fixture 14 , and the piston rods of the two second hydraulic cylinders 46 are fixedly connected to the bottom end of the U-shaped plate 44 .

[0063] Working principle: first step, start the first conveyor belt 53, the first conveyor belt 53 conveys the circuit board 54 to the left, the circuit board 54 slides down to the clamp 14 through the slide plate 42, and then starts the drive motor 6 to drive the second synchronous wheel 40 Rotate with the worm 7, and the worm 7 and the worm wheel 8 are meshed, the worm 7 drives the worm wheel 8 to rotate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com