Composite positive electrode material with array structure, and application thereof

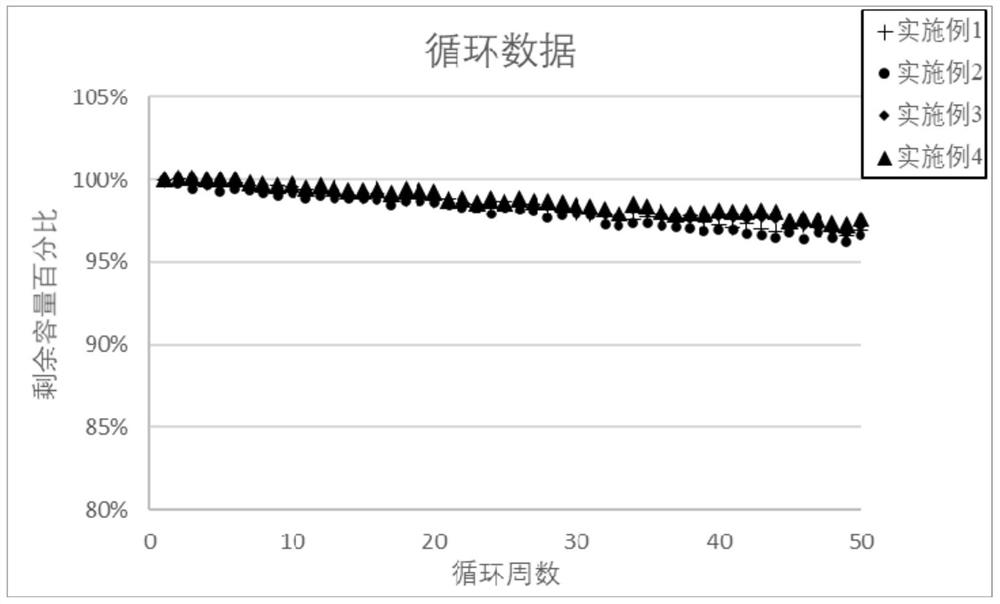

A composite positive electrode material and array structure technology, applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve the problems of unsuitable for large-scale production, unsatisfactory firmness, and low loading capacity, so as to improve the liquid absorption performance and cycle performance , inhibit the shuttle diffusion behavior, and ensure the effect of spatial structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

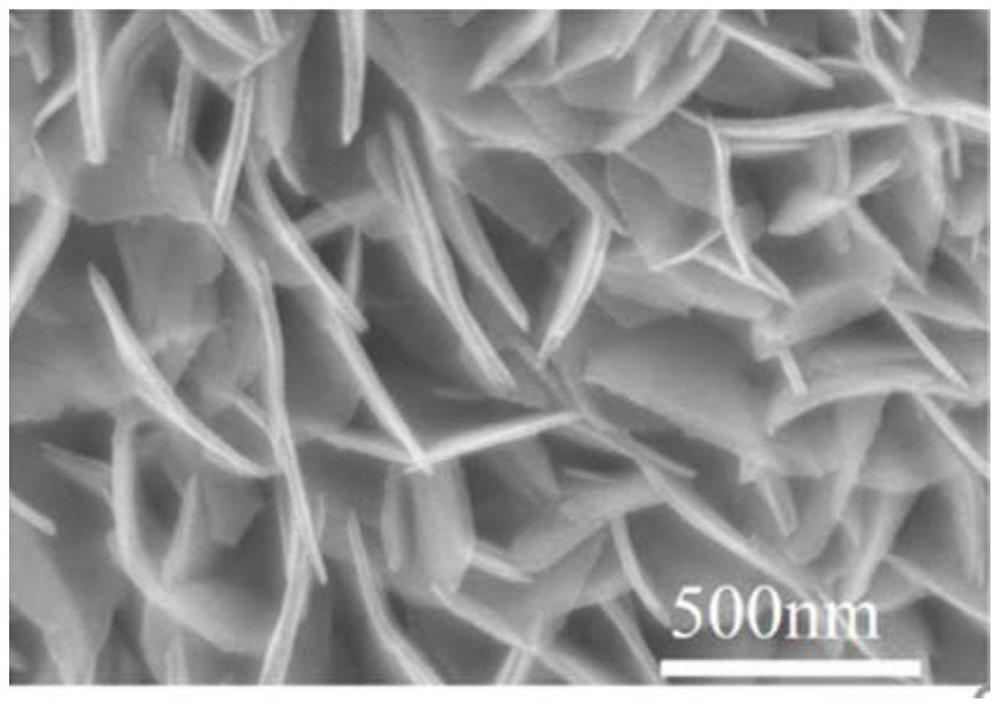

[0039] This embodiment provides a sulfur-tin oxide-graphene composite positive electrode material, and the specific preparation method includes the following steps:

[0040] Step 1, add 1 part (parts by mass) of thioacetamide and 1 part of tin tetrachloride to 2 parts of isopropanol solvents, ultrasonically dissolve and transfer to a polytetrafluoroethylene reactor, the reactor volume is 2 times the volume of the solution;

[0041] Step 2, 1 part of acetone, 1 part of nitric acid and 5 parts of graphene are added to the mixture obtained in step 1;

[0042] Step 3: React the reactor at 160°C for 24 hours.

[0043] After the reaction is completed, the product is dried in an oven at 80°C for 24 hours to obtain the substrate material precursor;

[0044] Step 4: Calcining the base material precursor at 500°C for 2 hours to obtain the array structure base material;

[0045] Step 5. Add 1 part of sulfur powder and 2 parts of base material to carbon sulfide, let it stand for 12 hou...

Embodiment 2

[0047] This embodiment provides a sulfur-tin oxide-carbon nanotube composite positive electrode material, and the specific preparation method includes the following steps:

[0048] Step 1, adding 1 part of thioacetamide and 1 part of tin tetrachloride to 2 parts of isopropanol solvent, ultrasonically dissolved and transferred to a polytetrafluoroethylene reactor whose volume is 2.3 times the volume of the solution;

[0049] Step 2, adding 1 part of acetone, 1 part of nitric acid and 6 parts of carbon nanotubes into the reactor containing the mixture of step 1;

[0050] Step 3: react the reactor at 170°C for 24 hours; after the reaction is completed, put the product in an oven at 80°C for 24 hours to obtain the substrate material precursor;

[0051] Step 4: Calcining the base material precursor at 500°C for 2 hours to obtain the array structure base material;

[0052] Step 5. Add 1 part of sulfur powder and 3 parts of base material to carbon sulfide, let it stand for 12 hours,...

Embodiment 3

[0054] This embodiment provides a sulfur-tin oxide-carbon nanohorn composite positive electrode material, and the specific preparation method includes the following steps:

[0055] Step 1. Add 1 part of thioacetamide and 1 part of tin tetrachloride to 2 parts of isopropanol solvent, ultrasonically dissolve and transfer to a polytetrafluoroethylene reactor whose volume is 2.7 times the volume of the solution;

[0056] Step 2, adding 1 part of acetone, 1 part of nitric acid and 7 parts of carbon nanohorns into the reactor containing the mixture of step 1;

[0057] Step 3, the reaction kettle was reacted at 180°C for 24 hours;

[0058]After the reaction is completed, the product is dried in an oven at 80°C for 24 hours to obtain the substrate material precursor;

[0059] Step 4: Calcining the base material precursor at 500°C for 2 hours to obtain the array structure base material;

[0060] Step 5. Add 1 part of sulfur powder and 4 parts of base material to carbon sulfide, let i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com