Connecting joint of steel frame structure externally-hung wall plate

A technology for hanging wall panels and connecting nodes, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of inconvenient installation and fixing, sliding wall panels, etc., and achieves the effect of convenient installation, avoiding welding and protecting connection nodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

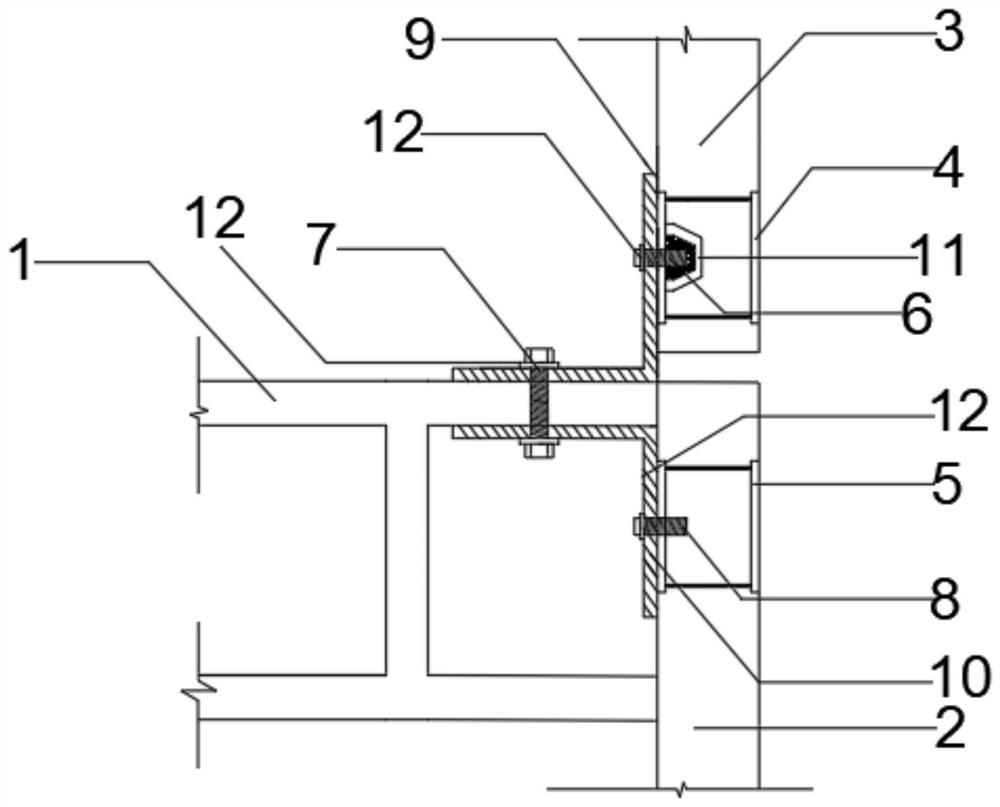

[0040] In order to better understand the purpose, structure and function of the present invention, a connection node of a steel frame structure external wall panel of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0041] The main advantages of the present invention are two points: the connection between the structural beam (1) and the lower end (3) of the external hanging wallboard (3) and the external hanging wallboard (2) and the arrangement of the damping device.

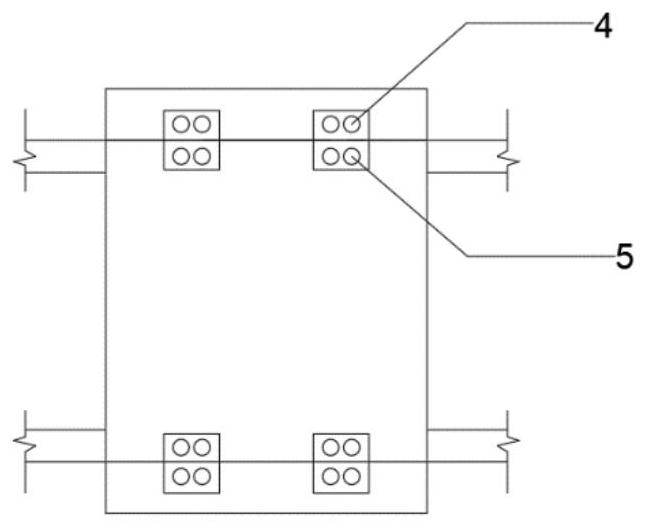

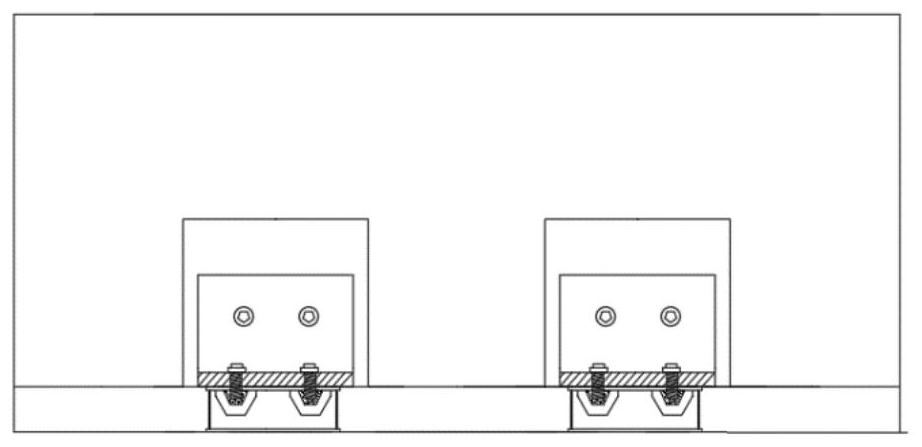

[0042] Such as figure 1 , figure 2 , image 3 , Fig. 4 (a), Fig. 4 (b), Fig. 5 (a), shown in Fig. 5 (b), a kind of connection node of steel frame structure external wall panel, comprises upper connection node and lower connection node;

[0043] The upper connection node includes a structural beam 1, a lower end 3 of an external wall panel, a first angle steel 9, a first embedded part 4, and a vibration damping device 11;

[0044] The structural beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com