Processing and impurity-removing pretreatment device for rosin related to raw materials for preparing terpilenol

A pretreatment device, terpineol technology, applied in the field of resin processing, can solve the problems of affecting product quality, wasting water, affecting the yield of rosin processing, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

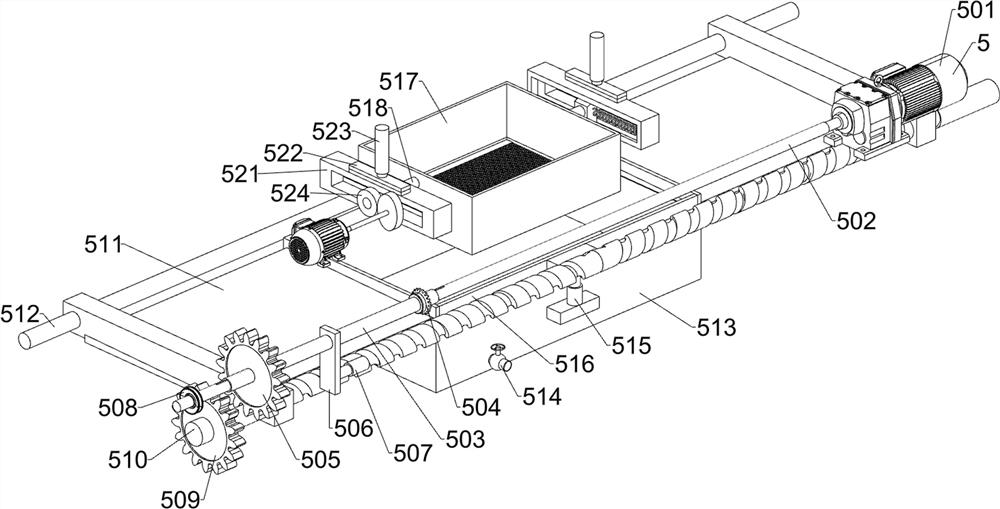

[0030] A kind of pine resin processing impurity removal pretreatment device related to terpineol preparation raw material, such as Figure 1-9 As shown, it includes a bottom frame 1, a support column 2, a backing plate 3, a crushing and screening assembly 4, a soaking impurity removal assembly 5, a fat water impurity removal assembly 6, a controller 7, an impurity collection box 8, a trapezoidal scraper 9, Grease water collection box 10 and waste water collection box 11; both sides of bottom frame 1 are connected with three sets of support columns 2; bottom frame 1 is connected with crushing and screening assembly 4; bottom frame 1 is connected with soaking impurity removal assembly 5; The frame 1 is connected with the fat water impurity removal assembly 6; the bottom frame 1 is connected with the controller 7; the bottom frame 1 is connected with the impurity collection box 8; the bottom frame 1 is connected with the trapezoidal scraper 9; The collection box 10 is connected; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com