Dynamically-vulcanized flame-retardant TPV composite material and preparation method thereof

A technology of dynamic vulcanization and composite materials, which is applied in the field of materials, can solve problems such as fire hazards, and achieve the effects of improving compatibility, improving interface adhesion, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of dynamic vulcanization flame-retardant TPV composite material, its preparation method comprises the following steps:

[0021] S1, mix thermoplastic vulcanizate, EPDM rubber, POE plastic, polypropylene, interface compatibilizer and flame retardant in a high-speed mixer according to a certain formula ratio, and then add it to a twin-screw extruder for melt extrusion , to obtain an intermediate;

[0022] S2, then use twin-screw extruder to carry out dynamic vulcanization after the intermediate and vulcanizing agent double-25 are mixed in a certain proportion, and prepare dynamic vulcanized flame-retardant TPV pellets after water cooling, drawing, and pelletizing;

[0023] S3, after the pellets are vacuum-dried at 100°C, they are injected into samples with a vertical injection molding machine, and then made into samples with a standard cutter for performance testing.

[0024] S1 90 parts of thermoplastic vulcanizate, 50 parts of EPDM rubber, 40 parts of POE plasti...

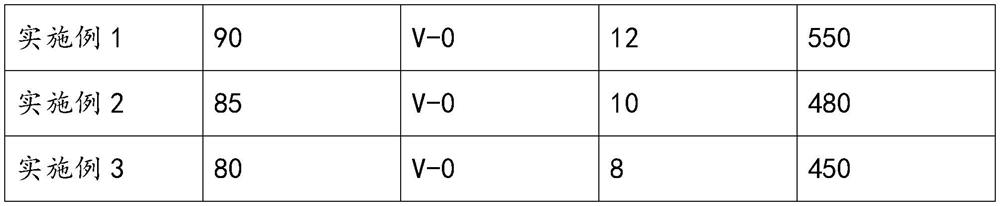

Embodiment 1

[0027] Example 1: Mix the formula ratio of 90 parts of thermoplastic vulcanizate, 50 parts of EPDM rubber, 40 parts of POE plastic, 10 parts of polypropylene, 50 parts of interface compatibilizer and 10 parts of flame retardant in a high-speed mixer , and then added to a twin-screw extruder to melt and extrude, the extrusion temperature is 190-200 ° C, and the intermediate is obtained; then the intermediate and the vulcanizing agent Shuang-25 are mixed at a ratio of 5:2, and then the twin-screw The extruder performs dynamic vulcanization, the extrusion temperature is 180-190°C, and the dynamic vulcanization and flame-retardant TPV pellets are prepared after water cooling, drawing, and pelletizing; after the pellets are vacuum-dried at 100°C, they are processed by a vertical injection molding machine Injection molded into samples, and then made samples with standard cutting knife for performance testing.

Embodiment 2

[0028] Example 2: Mix the formula ratio of 90 parts of thermoplastic vulcanizate, 50 parts of EPDM rubber, 40 parts of POE plastic, 10 parts of polypropylene, 50 parts of interfacial compatibilizer and 15 parts of flame retardant in a high-speed mixer , and then added to a twin-screw extruder to melt and extrude, the extrusion temperature is 190-200 ° C, and the intermediate is obtained; then the intermediate and the vulcanizing agent Shuang-25 are mixed at a ratio of 5:2, and then the twin-screw The extruder performs dynamic vulcanization, the extrusion temperature is 180-190°C, and the dynamic vulcanization and flame-retardant TPV pellets are prepared after water cooling, drawing, and pelletizing; after the pellets are vacuum-dried at 100°C, they are processed by a vertical injection molding machine Injection molded into samples, and then made samples with standard cutting knife for performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com