adhesive sheet

An adhesive sheet and non-adhesive technology, applied in the direction of adhesives, film/sheet adhesives, synthetic resin layered products, etc., can solve chip flying, adhesive sheet and adherend bonding area reduction Small and other problems, to achieve the effect of good interface adhesion, excellent adhesion and heat peelability, and less residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

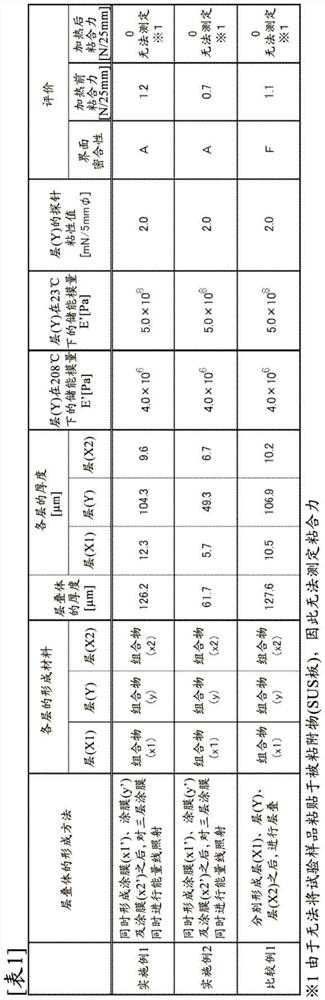

[0285] In this invention, although the following Example demonstrates concretely, this invention is not limited to the following Example. In addition, the physical property value in the following manufacture example and an Example is the value measured by the following method.

[0286]

[0287] The value measured by gel permeation chromatography (manufactured by Tosoh Corporation, product name "HLC-8020") under the following conditions and measured in terms of standard polystyrene was used.

[0288] (measurement conditions)

[0289] ・Column: "TSK guard column HXL-L", "TSK gel G2500HXL", "TSK gel G2000HXL", "TSKgel G1000HXL" (all manufactured by Tosoh Corporation) are connected in sequence

[0290] ·Column temperature: 40℃

[0291] Elution solvent: tetrahydrofuran

[0292] ·Flow rate: 1.0mL / min

[0293]

[0294] Measurement was performed using a constant pressure thickness measuring instrument (model: "PG-02J", standard: based on JIS K6783, Z1702, Z1709 standard) manufa...

manufacture example 1

[0325] Production Example 1 (Preparation of Composition (x1))

[0326] (1) Synthesis of urethane acrylate oligomers

[0327] 100 parts by mass of polypropylene glycol having a weight average molecular weight of 3,000 (solid content conversion; the same applies hereinafter), 4 parts by mass of hexamethylene diisocyanate, and 0.02 parts by mass of dioctyltin dilaurate were mixed, and stirred at 80° C. for 6 hours , thus obtaining the reactants. The IR spectrum of the obtained reactant was measured by infrared spectroscopy, and it was confirmed that the isocyanate group almost disappeared.

[0328] Then, 1 mass part of 2-isocyanatoethyl acrylate was mixed with respect to the obtained reactant whole quantity, it stirred at 80 degreeC for 3 hours, and obtained the urethane acrylate oligomer. The IR spectrum of the obtained urethane acrylate oligomer was measured by infrared spectroscopy, and it was confirmed that the isocyanate group almost disappeared. Moreover, when the molecu...

manufacture example 2

[0334] Production Example 2 (Preparation of Composition (y))

[0335] 2-Hydroxyethyl acrylate was reacted with a terminal isocyanate urethane prepolymer to obtain a 2-functional acrylic urethane oligomer with a weight average molecular weight (Mw) of 5000. The terminal isocyanate urethane The prepolymer is obtained by reacting ester diol and isophorone diisocyanate (IPDI).

[0336] Then, 40 mass % (solid content ratio) of isobornyl acrylate (IBXA) as an energy ray polymerizable monomer was blended into 40 mass % (solid content ratio) of the urethane acrylate oligomer synthesized above, and Phenyl hydroxypropyl acrylate (HPPA) 20% by mass (solid content ratio), with respect to the total amount (100 parts by mass) of the acrylic urethane oligomer and the energy ray polymerizable monomer 2.0 parts by mass (solid content ratio) of 1-hydroxycyclohexyl phenyl ketone (manufactured by BASF Corporation, product name "Irgacure 184") as an initiator, and 0.2 mass parts (solid content ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com