Two-component nano sol type liquid hardening agent and preparation method thereof

A nano-sol and hardener technology, applied in the field of building materials, can solve the problems such as the lack of two-component coordination, the synergistic reinforcement of the base surface, the inability to change and further change the subsequent reaction direction, the inability to improve the hardness and wear resistance of concrete, etc. Achieve the effect of improving overall aesthetics, improving service life and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

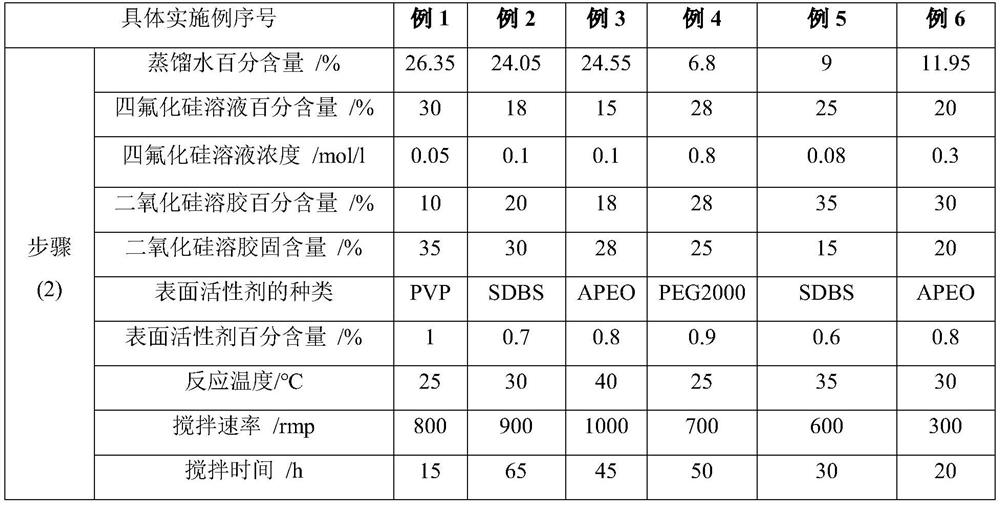

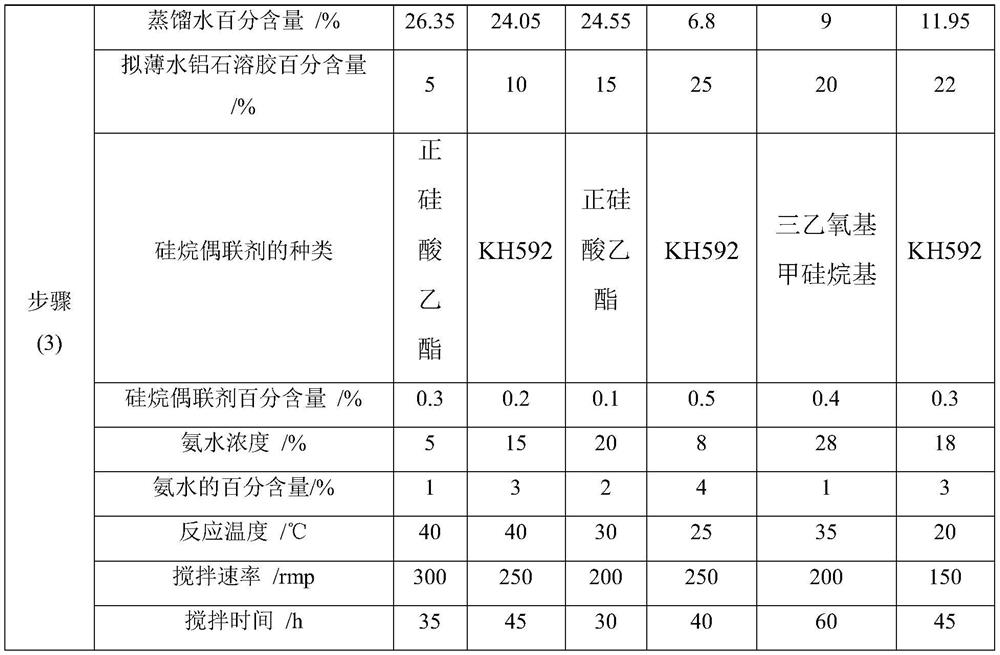

[0040]The two-component nano-sol type liquid curing agent provided by the present invention is composed of a component A solution and a component B solution. Among them, the component A solution is mixed with the following components: 15-30% silicon tetrafluoride solution with a concentration of 0.05-0.8mol / l, 10-35% silica sol with a solid content of 15%-35%, surface active Agent 0.6-1%, distilled water; component B solution is mixed with the following components: pseudo-boehmite 5-25%, ammonia water with a mass fraction of 5%-28% 1-4%, silane coupling agent 0.1- 0.5%, distilled water; the percentages of each component in the described component solutions are mass ratios, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com