Connecting rod type multi-adjustment sweeper

A sweeper and link-type technology, which is used in cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as narrow working space, inability to carry blades, and large hopper depth, and can solve structural technical problems and reduce belts. Injury risk, the effect of reducing the technical requirements of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further specific embodiments of the present invention, the following detailed description and accompanying drawings.

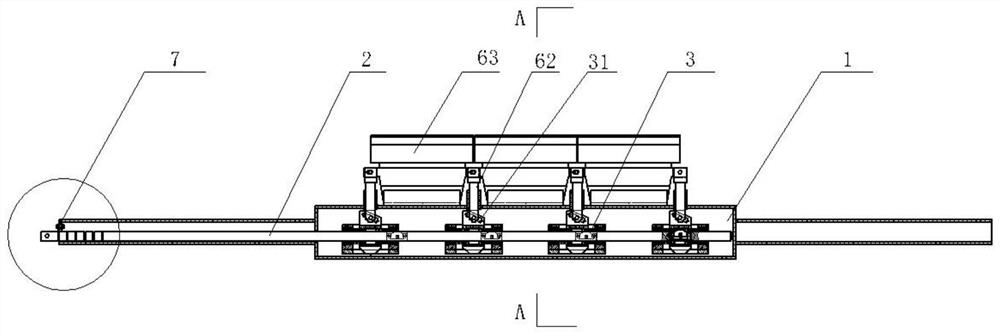

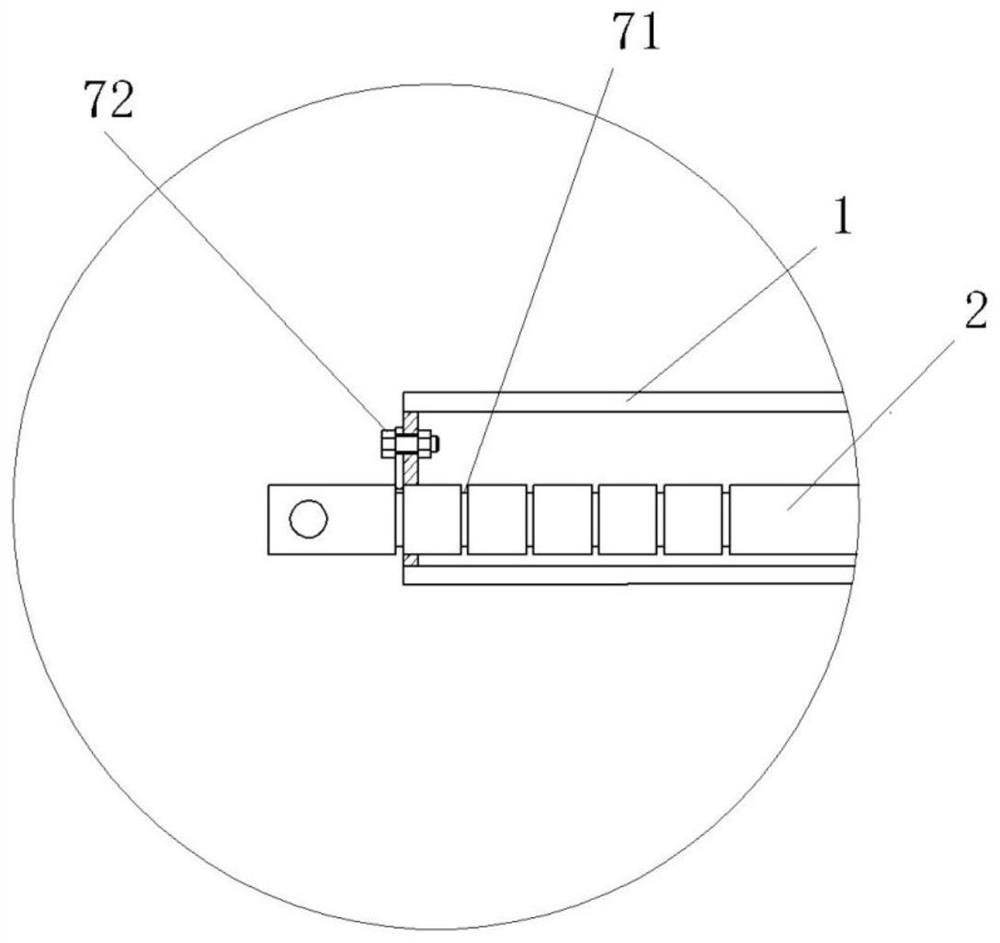

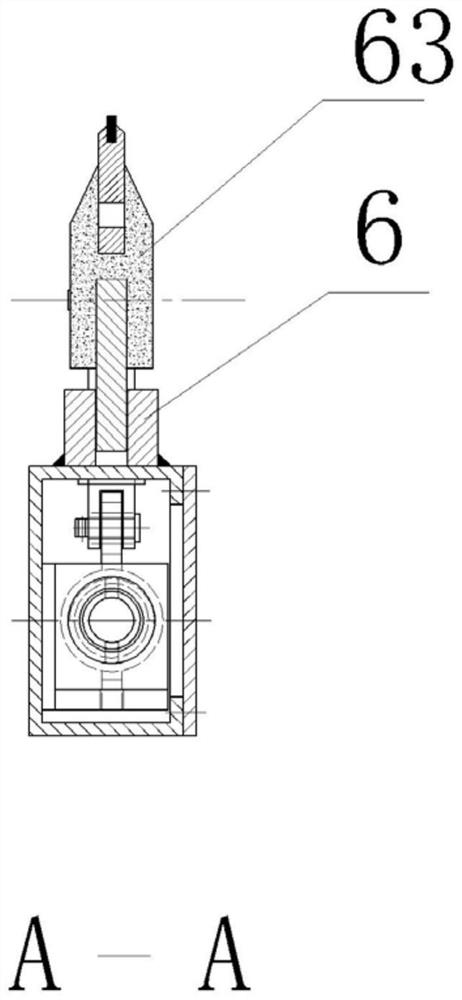

[0019] like Figure 1-5 As shown in, for example, the cleaning main body 1 of the present embodiment, the cleaning body is provided with an adjusting lever 2, a plurality of adjustment unit 3, the adjustment unit 4 has a key groove 3, the adjusting lever 2 is provided with a plurality of after a spaced movable key 5, the adjusting lever 2 is rotated and adjustment unit 3 is connected between the adjusting mechanism provided on the blade unit 36, the movable key 4 and the keyway 5 engages with the adjusting unit adjusting lever 2 3 may be driven by the relative rotation mechanism 6 vertically moving blade. Tilt mechanism 6 includes a blade support mechanism 61, is provided on the tilt support mechanism 61 of the jack 62, the jack 62 is fixed to the side of the blade 63, a synchronization control jack can lift two adjacent blades.

[0020] Threaded sleeve 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com