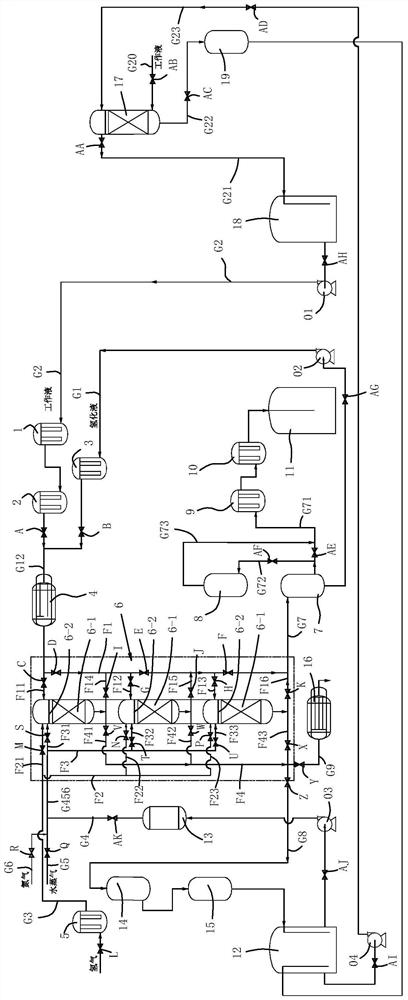

Method for prolonging service life of palladium catalyst of hydrogenation tower and hydrogenation tower system thereof

A technology of palladium catalyst and hydrogenation tower, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, chemical recovery, etc., can solve the problem of incomplete regeneration of palladium catalyst Impurity removal, degradation products cannot be effectively cleaned, and the activity level cannot be restored, so as to achieve the effect of improving regeneration effect, saving steam consumption, and extending regeneration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

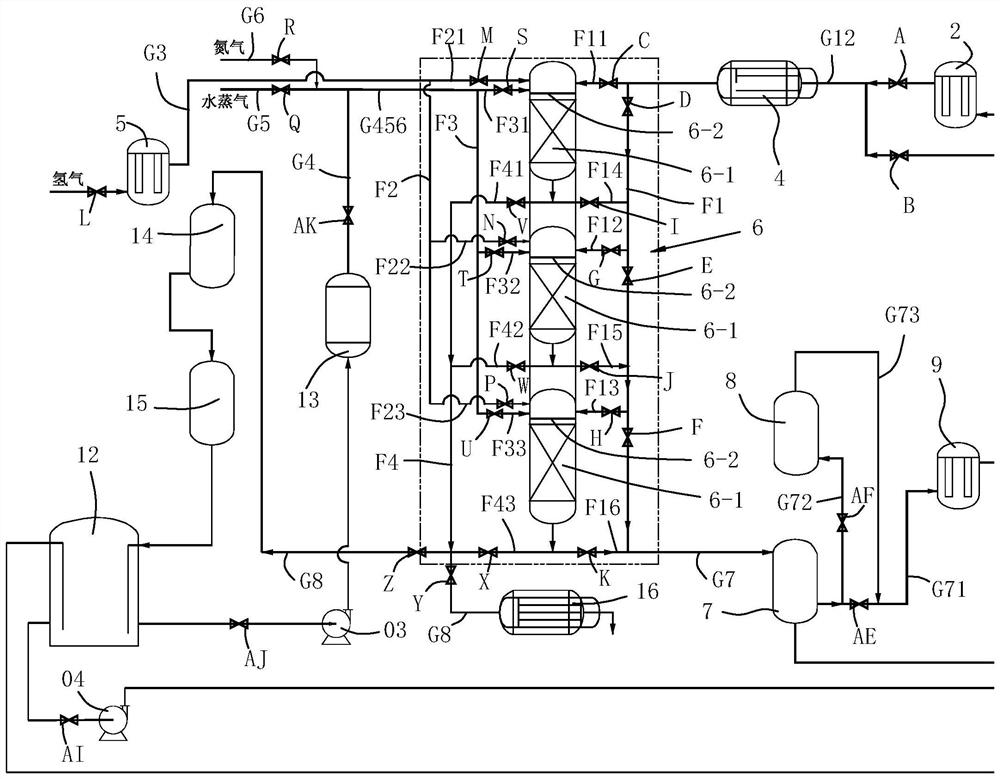

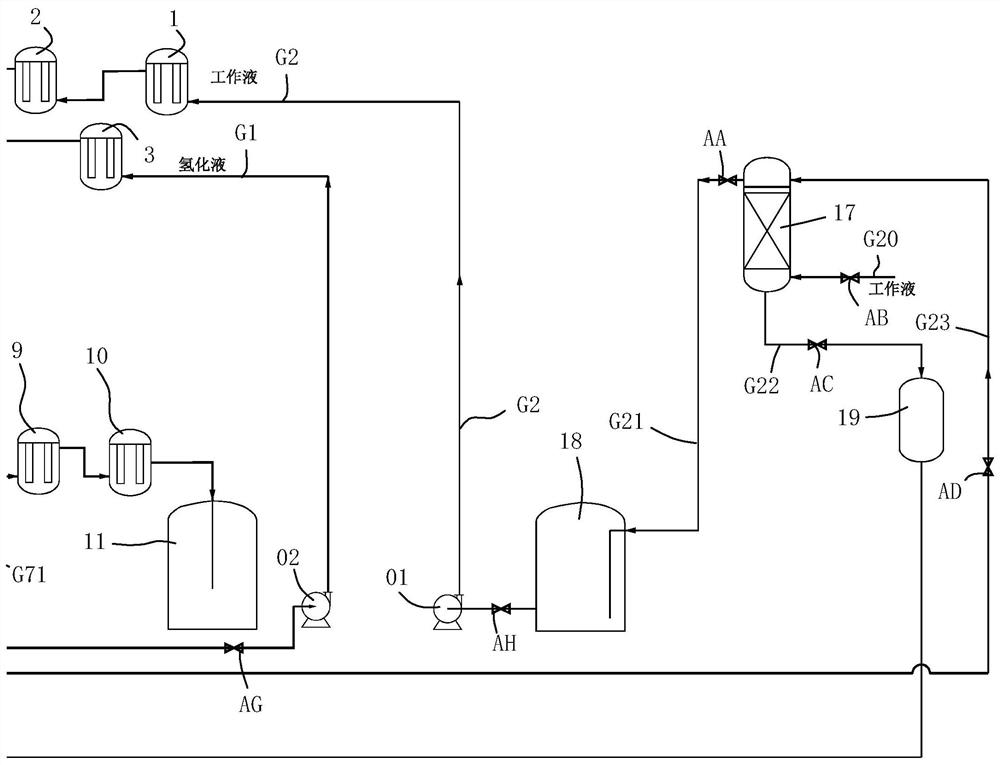

[0063] Among the three hydrogenation tower units, the uppermost hydrogenation tower unit is connected in series with the middle hydrogenation tower unit, and when the lowermost hydrogenation tower unit is in regeneration or standby state after regeneration, please refer to the description below for the switching status of the corresponding two-way valve :

[0064] The working fluid from the working fluid circulation pump 01 first passes through the primary working fluid filter 1 and then the secondary working fluid filter 2 to filter out solid impurities that may be entrained, and then passes through the opened two-way valve A, together with the hydrogenation fluid circulation pump. 02 and after the hydrogenated liquid that has passed through the circulating hydrogenated liquid filter 3 is mixed (at this time, the two-way valve B is opened), it is preheated to the required temperature through the working fluid preheater 4, and the two-way valves D, V, E, W, H and K are closed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com