A magnetism-preserving and guiding assembly method for an alnico-type magnetic steel self-contained torque motor

A technology of torque motors and assembly methods, applied in the direction of motors, motor generators, electric components, etc., can solve problems such as inappropriate magnetic preservation, achieve the effects of reducing magnetic performance loss, ensuring concentric installation, and avoiding bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure of the present invention will be further described below with reference to the accompanying drawings and through embodiments. It should be noted that this embodiment is descriptive, not restrictive.

[0033] In the specific embodiment of the present invention, in order to better describe the implementation method and process, general necessary structural descriptions and explanations are made for the self-contained motor and magnetic head device of AlNiCo magnetic steel, and it is not excluded that it includes other Structure and components, the present invention does not limit the detailed design and structure of its interior, the structural type and technical scheme of the integral motor and the magnetic charging head device of AlNiCo magnetic steel can meet the relevant requirements of the embodiment of the present invention. .

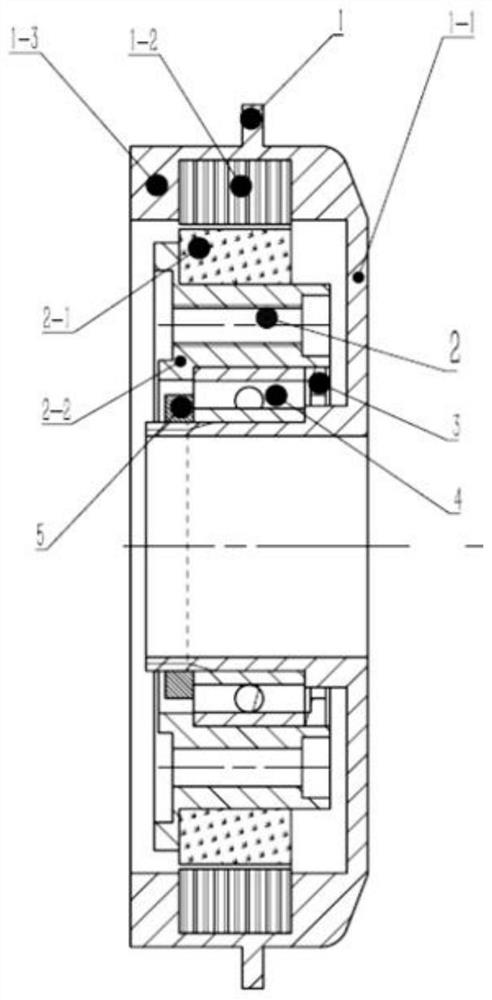

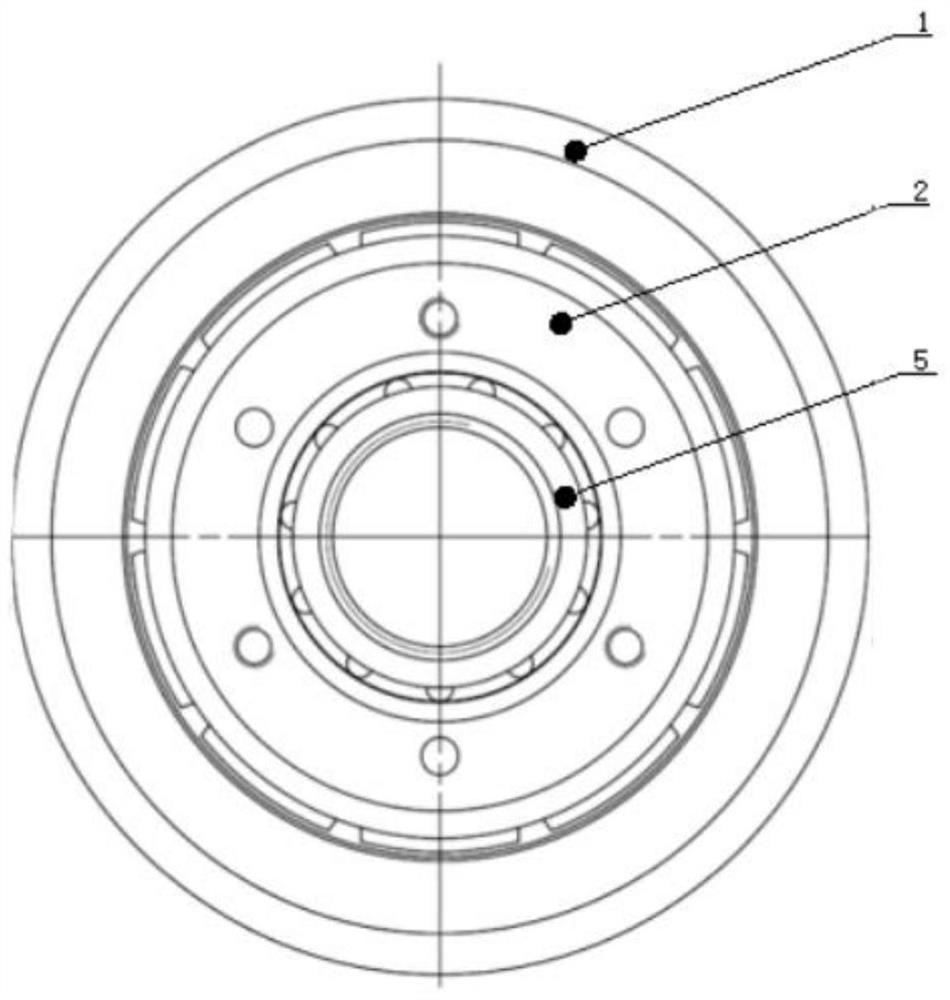

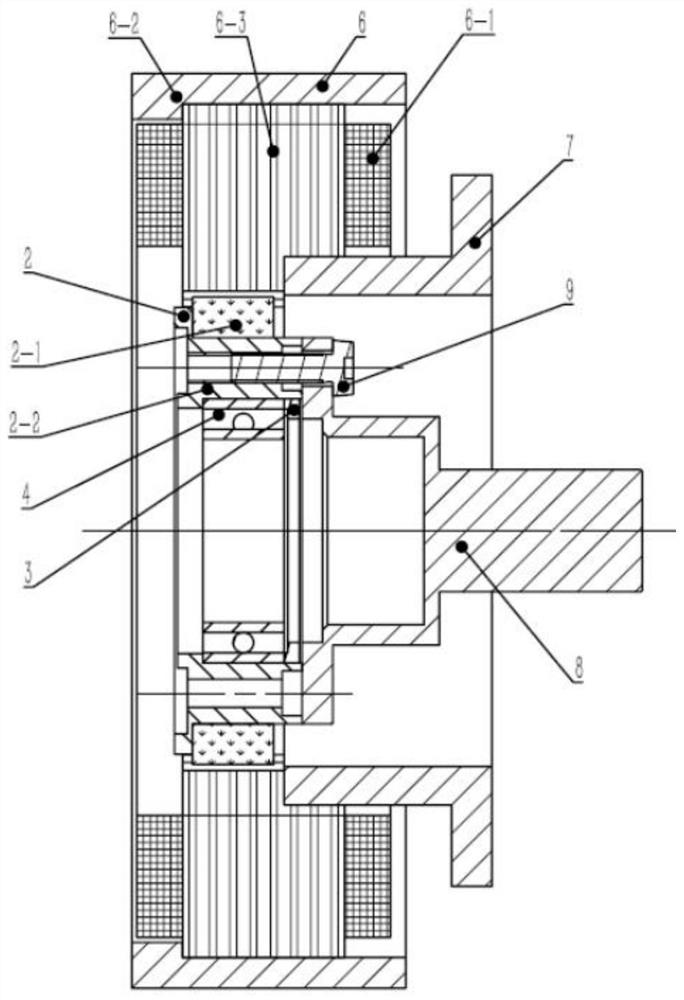

[0034] like Figure 1a and 1b Shown: the AlNiCo type magnetic steel integral motor is composed of a rotor 1 , a stator 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com