Large-capacity sample bearing device for hollow turbine blade detection

A sample carrying device, turbine blade technology, applied in measurement devices, workpiece clamping devices, material analysis using wave/particle radiation, etc., can solve problems such as turbine blade tipping, neutron beam waste, etc., to ensure stability , improve detection efficiency, reduce the risk of radiation and the effect of neutron beam waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Those skilled in the art will appreciate that the embodiments described here are to help readers understand the principles of the present invention, and it should be understood that the protection scope of the present invention is not limited to such specific statements and embodiments. Those skilled in the art can make various other specific modifications and combinations based on the technical revelations disclosed in the present invention without departing from the essence of the present invention, and these modifications and combinations are still within the protection scope of the present invention.

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

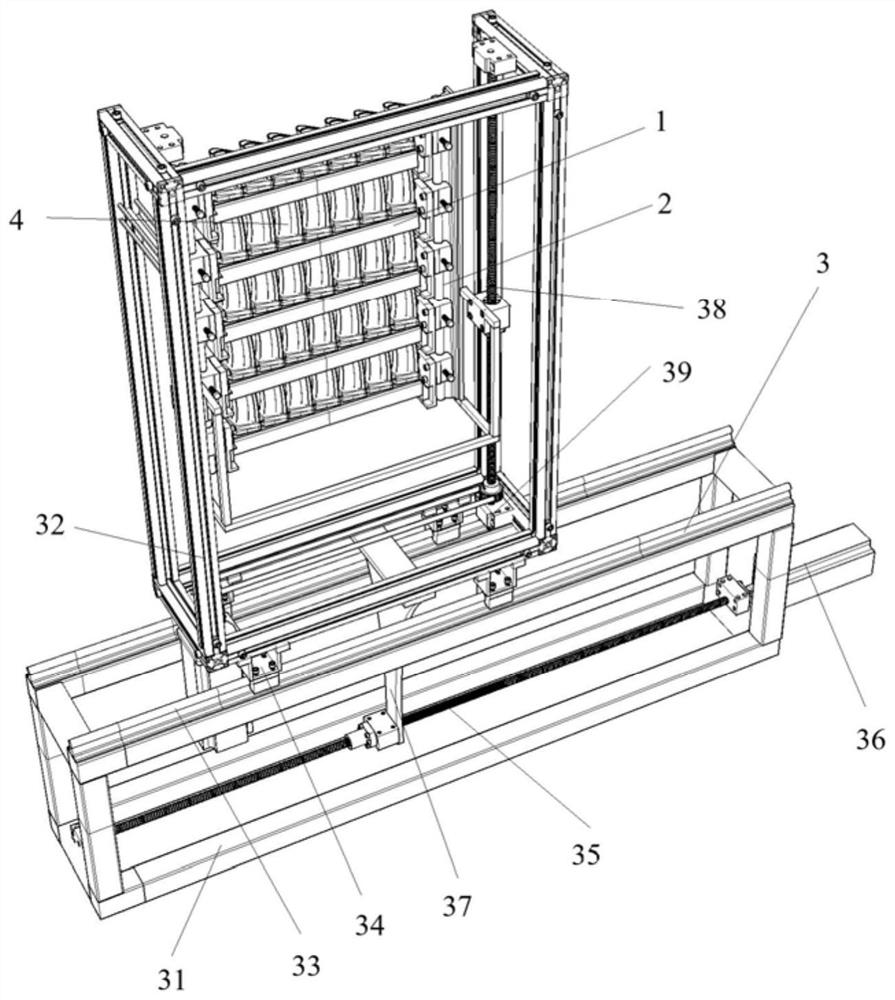

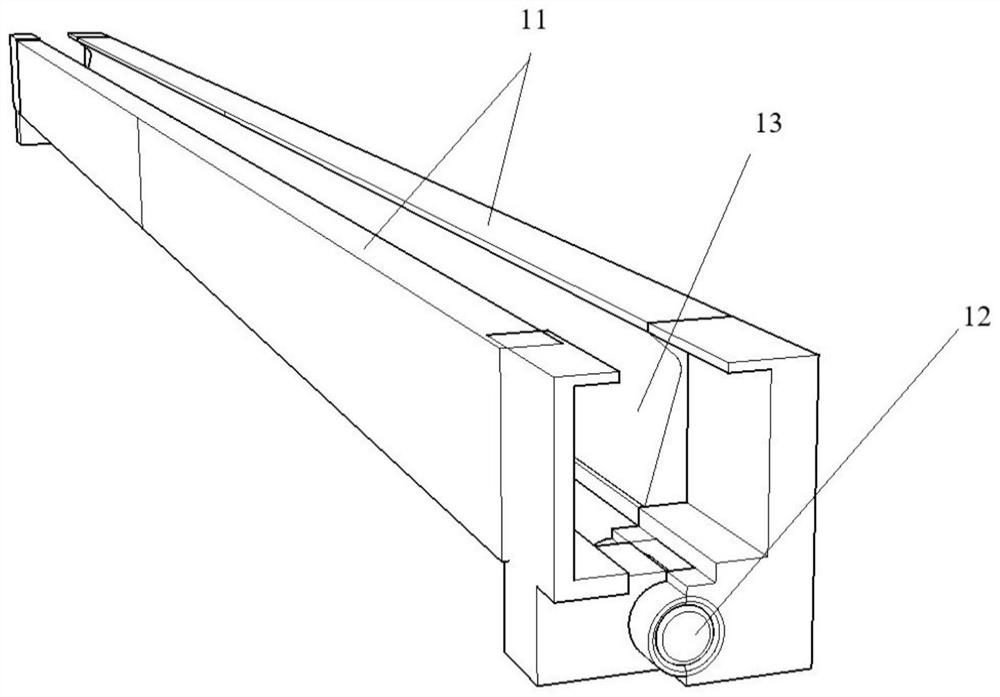

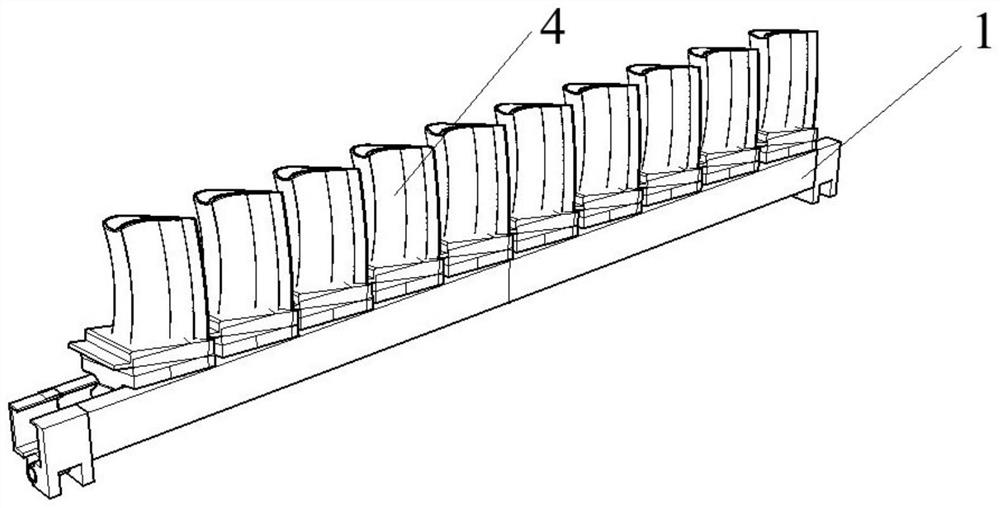

[0019] As shown in Figure 1, a large-capacity sample carrying device for hollow turbine blade detection, the device includes: a blade clamping box 1, a clamping box mounting frame 2 and a two-dimensional moving mechanism 3, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com