Prussian blue analogue nano framework material as well as preparation method and application thereof

A technology of Prussian blue and frame materials, applied in the direction of separation methods, chemical instruments and methods, chemical/physical processes, etc., to achieve high selectivity and photocatalytic efficiency, simple and easy access to equipment, and the effect of photocatalytic reduction with high efficiency and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

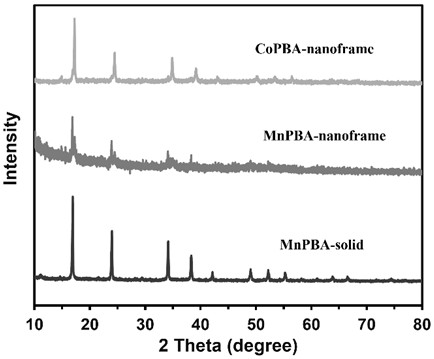

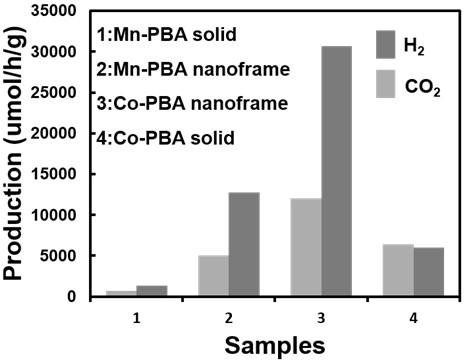

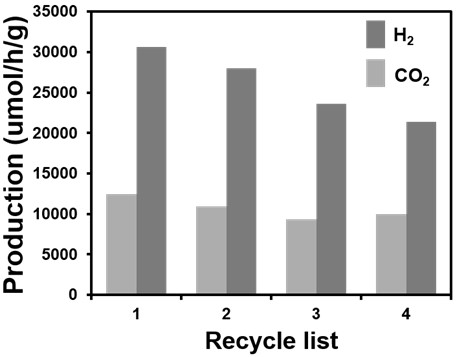

Method used

Image

Examples

Embodiment 1

[0054] Preparation of Co / Fe PBAs nanoframe material:

[0055] (1) Weigh 0.106 g of iron sulfate Fe with an electronic balance 2 (SO4) 3 and 0.270 g manganese sulfate monohydrate MnSO 4 ·H 2 0, 1.5 g polyvinylpyrrolidone PVP, measure 100 ml ethanol, 100 ml deionized water with graduated cylinder, mix the three;

[0056] (2) Then the mixture was stirred under magnetic stirring for 10 minutes, and ultrasonicated for 5 minutes to obtain a uniform mixed solution A;

[0057] (3) Weigh 6.585 g of potassium ferricyanide K with an electronic balance 3 Fe(CN) 6 , Measure 100 ml of deionized water with a graduated cylinder, and mix to form a uniform mixed solution B;

[0058] (4) The mixed solution B was added to the mixed solution A, stirred magnetically for 30 min, centrifuged to obtain a precipitate, washed twice with ethanol and deionized water twice, and freeze-dried for 6 h to obtain Mn / Fe PBAs nanocomposites.

[0059] (5) Weigh 20 mg of Mn / Fe PBAs nanocomposite material wit...

Embodiment 2

[0063] Preparation of Ni / Fe PBAs nanoframe material:

[0064] (1) Weigh 0.106 g of iron sulfate Fe with an electronic balance 2 (SO4) 3 and 0.270 g manganese sulfate monohydrate MnSO 4 ·H 2 0, 1.5 g polyvinylpyrrolidone PVP, measure 100 ml ethanol, 100 ml deionized water with graduated cylinder, mix the three;

[0065] (2) Then the mixture was stirred under magnetic stirring for 10 minutes, and ultrasonicated for 5 minutes to obtain a uniform mixed solution A;

[0066] (3) Weigh 6.585 g of potassium ferricyanide K with an electronic balance 3 Fe(CN) 6 , Measure 100 ml of deionized water with a graduated cylinder, and mix to form a uniform mixed solution B;

[0067] (4) The mixed solution B was added to the mixed solution A, stirred magnetically for 30 min, centrifuged to obtain a precipitate, washed twice with ethanol and deionized water twice, and freeze-dried for 6 h to obtain Mn / Fe PBAs nanocomposites.

[0068] (5) Weigh 20 mg of Mn / Fe PBAs nanocomposite material wit...

Embodiment 3

[0072] Preparation of Cu / Fe PBAs nanoframe material:

[0073] (1) Weigh 0.106 g of iron sulfate Fe with an electronic balance 2 (SO4) 3 and 0.270 g manganese sulfate monohydrate MnSO 4 1H 2 0, 1.5 g polyvinylpyrrolidone PVP, measure 100 ml ethanol, 100 ml deionized water with graduated cylinder, mix the three;

[0074] (2) Then the mixture was stirred under magnetic stirring for 10 minutes, and ultrasonicated for 5 minutes to obtain a uniform mixed solution A;

[0075] (3) Weigh 6.585 g of potassium ferricyanide K with an electronic balance 3 Fe(CN) 6 , Measure 100 ml of deionized water with a graduated cylinder, and mix to form a uniform mixed solution B;

[0076] (4) The mixed solution B was added to the mixed solution A, stirred magnetically for 30 min, centrifuged to obtain a precipitate, washed twice with ethanol and deionized water twice, and freeze-dried for 6 h to obtain Mn / Fe PBAs nanocomposites.

[0077] (5) Weigh 20 mg of Mn / Fe PBAs nanocomposite material wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com