Connection method of large-diameter high-pressure fiber-reinforced flexible composite pipe

A flexible composite pipe, fiber reinforced technology, applied in the direction of hose connection device, pipe connection arrangement, pipe/pipe joint/pipe fitting, etc. High-pressure pipelines and other problems, to avoid stress concentration, high-strength connection, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

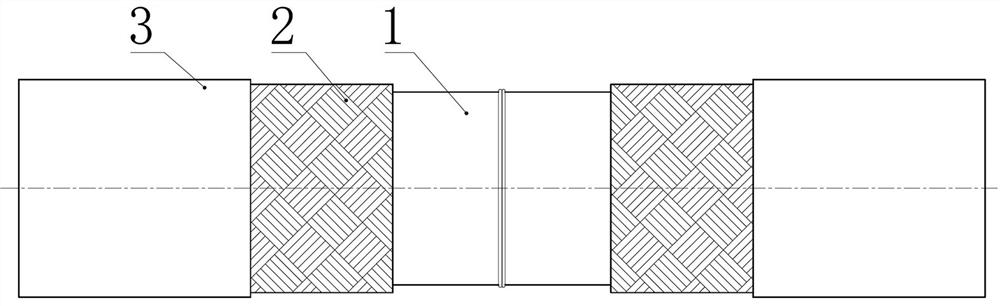

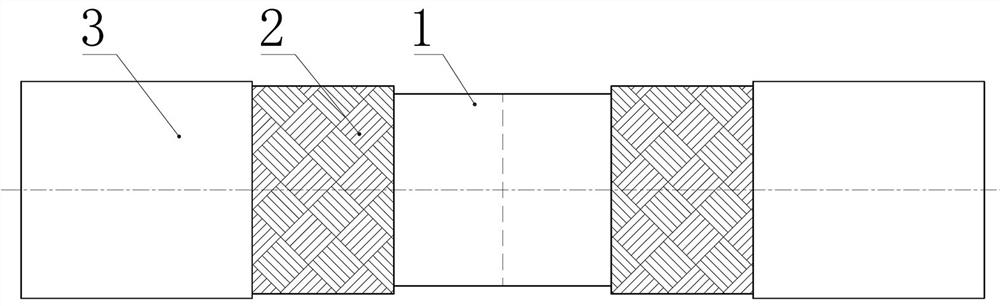

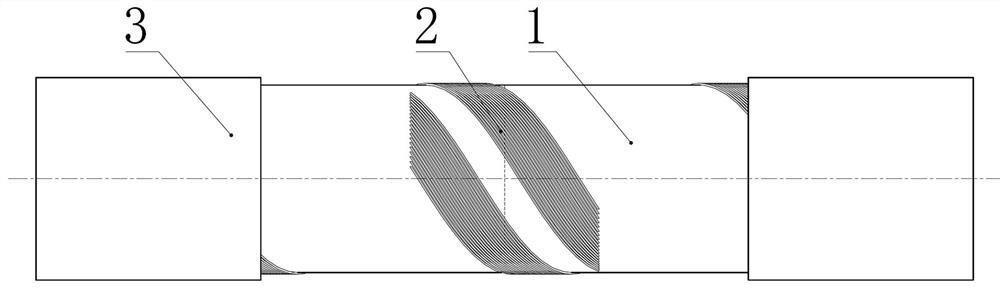

[0042] Inner lining layer 1 has a pipe inner diameter of 700mm. Inner lining layer 1 is made of polyethylene pipe with a wall thickness of 26mm. Reinforcement layer 2 is made of aramid fiber. Reinforcement layer 2 contains 10 layers of fibers with a total thickness of 20mm. The angle is 55°, and the winding directions of the fibers are opposite between adjacent layers of the reinforcement layer 2 . The overlapping length of the innermost layer of fibers at the joint is 1300 mm, the overlapping length of the outermost layer of fibers is 900 mm, and the overlapping lengths of the middle layers are evenly transitioned. After the reinforcing layer is wound, a polyethylene tape is wrapped on the outside of the butt joint as a protective layer 3, and the thickness of the protective layer 3 is about 4 mm.

[0043]Through experiments and finite element analysis with the help of the Tsai-Wu criterion, the burst pressure of the pipeline described in Embodiment 1 is close to 34 MPa, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com