Plate chamfering device for numerical-control machine tool

A technology of CNC machine tools and chamfering devices, which is applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of increasing the workload of staff and reducing the working efficiency of the device, and achieves increasing labor costs, reducing labor, The effect of increasing the efficiency of chamfering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

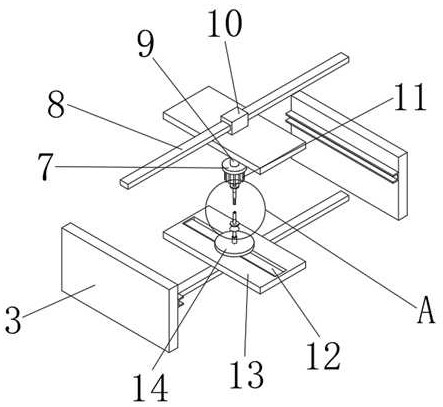

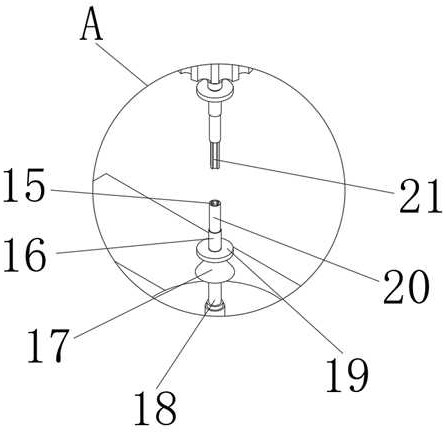

[0029] refer to Figure 1-6, a plate chamfering device for a CNC machine tool, comprising a workbench 1, the four corners of the top outer wall of the workbench 1 are connected with support rods 4 by bolts, and the top outer wall of the support rod 4 is connected with the same top plate 5 by bolts, and the work The four corners of the bottom outer wall of table 1 are connected with support legs 2 by bolts, and the bottom outer walls of support legs 2 are connected with anti-skid pads by bolts, and the bottom outer wall of top plate 5 and the top outer wall of workbench 1 are fixedly equipped with position adjustment mechanisms , and the bottom of the position adjustment mechanism at the top is provided with a first electric push rod 9, the bottom outer wall of the first electric push rod 9 is connected with a motor mounting plate 7 by bolts, and the bottom outer wall of the motor mounting plate 7 is connected with a rotating shaft by bolts The motor 11, the top outer wall of t...

Embodiment 2

[0035] refer to Figure 1-7 , a plate chamfering device for a CNC machine tool, the position adjustment mechanism at the bottom is replaced by a first slide rail 32, the outer wall of the first slide rail 32 is slidably provided with a fourth slider 31, and the outer wall of the fourth slider 31 The sliding plate 30 is connected by bolts, the outer wall of the sliding plate 30 is fixedly provided with the second sliding rail 29, and the outer wall of the second sliding rail 29 is slidably provided with the fifth slider, and the outer wall of the fifth sliding block is connected with the second sliding block by bolts. The electric push rod mounting plate, and two connecting frames 28 are connected by bolts between the outer peripheral wall of the second electric push rod mounting plate and the peripheral outer wall of the first electric push rod mounting plate 14 .

[0036] Working principle: Before grinding, install the plate on the clamping key 6, drive the first slider 10 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com