Intelligent pressure detection device for metal product stamping

A detection device and a metal product technology, applied in the field of metal product stamping, can solve problems such as large forming error of metal product sheet, damage to the upper die stamping device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

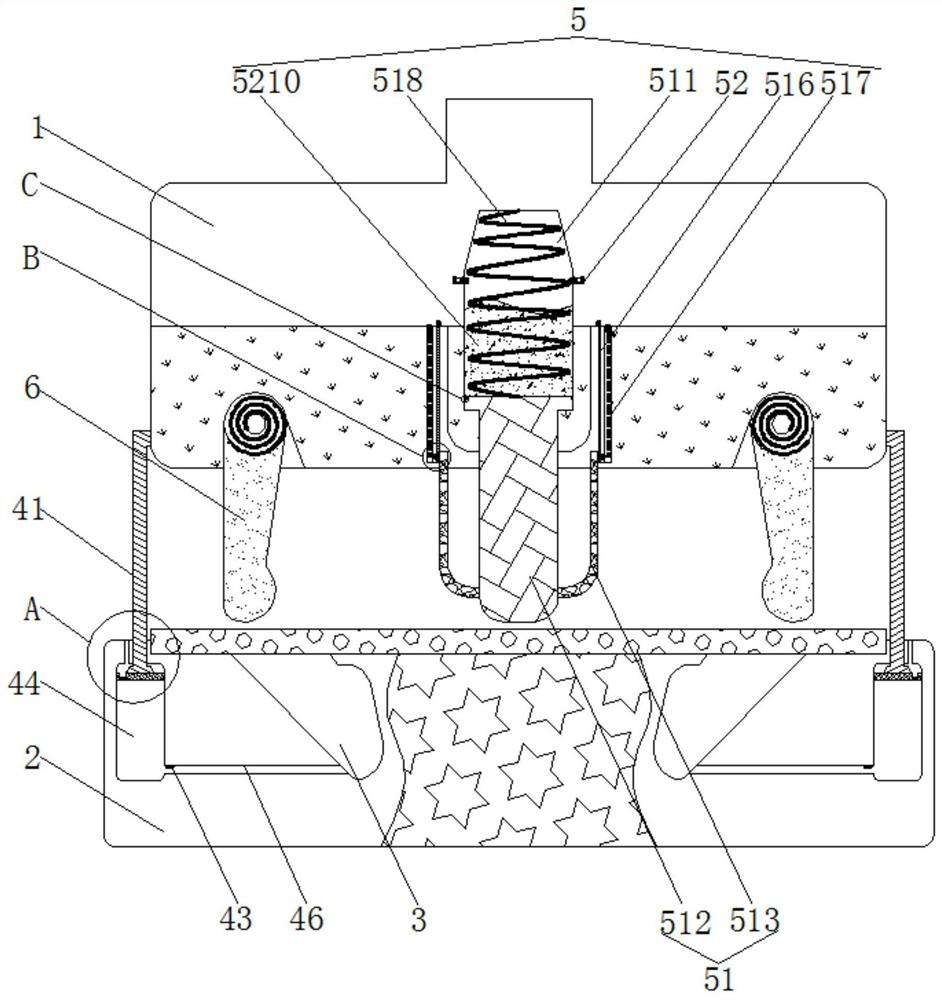

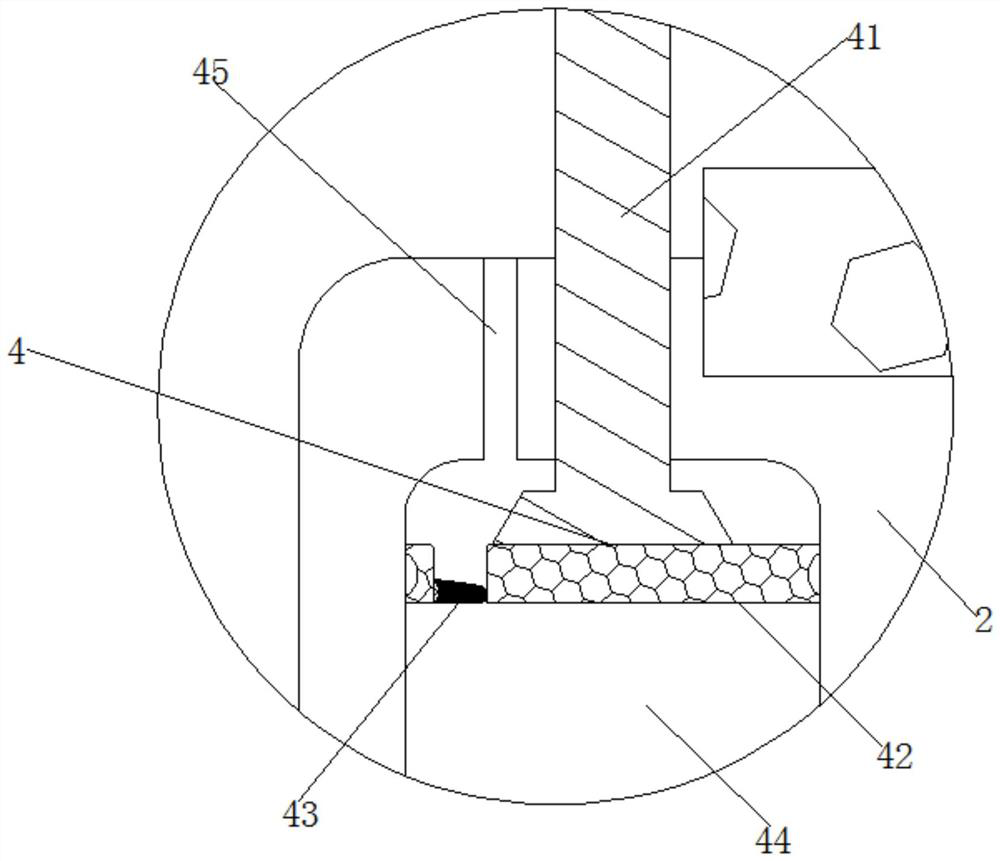

[0026] see Figure 1-2 , an intelligent pressure detection device for stamping metal products, including an upper mold 1 and a lower mold 2, two symmetrical extrusion grooves 3 are opened on the surface of the lower mold 2, and auxiliary metal plates are arranged inside the lower mold 2 Fully formed quality assurance mechanism4.

[0027] The specifications of the upper mold 1 match the specifications of the lower mold 2, the specifications of the extrusion groove 3 match the specifications of the forming rod 6, a coil spring with a rotary reset function is arranged between the forming rod 6 and the upper mold 1, and the quality preservation mechanism 4 includes extrusion rod 41, which is fixedly connected to the outside of the upper mold 1 and slidingly connected to the lower mold 2, the piston 42 is fixedly connected to the bottom of the extrusion rod 41, and the check valve 43 is movably connected to the inside of the piston 42 , the air groove 44 is arranged in the inside ...

Embodiment 2

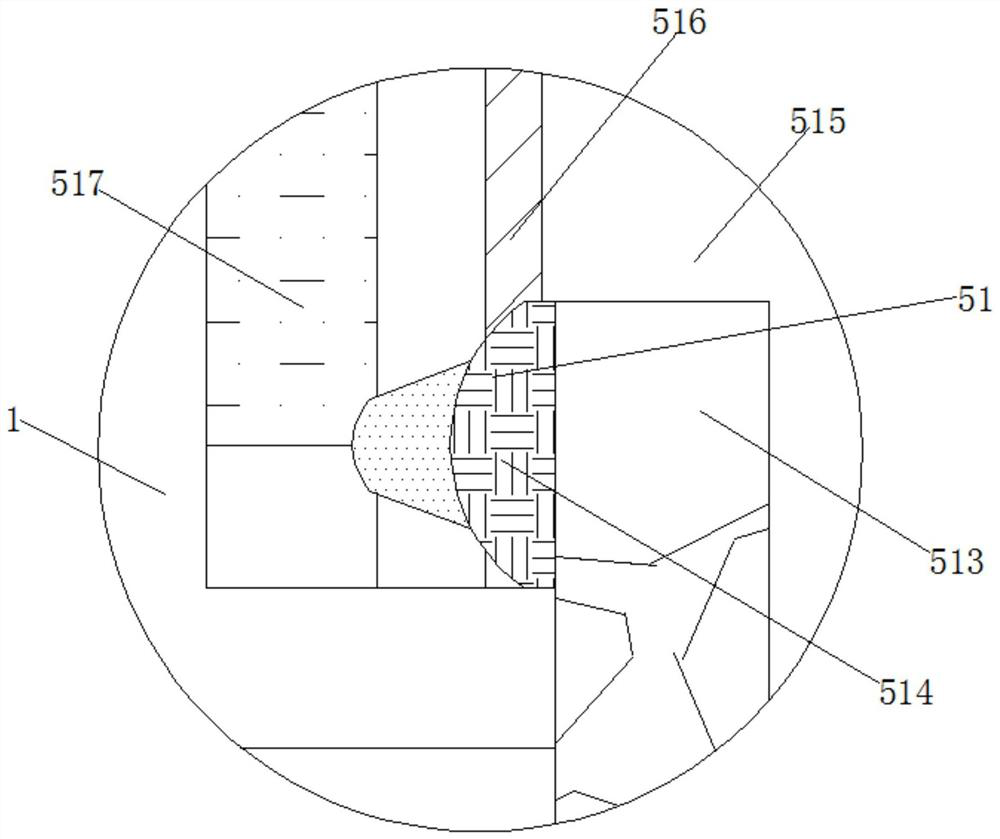

[0031] seefigure 1 , 3 , 4, 5, an intelligent pressure detection device for stamping metal products, including an upper mold 1 and a lower mold 2, the surface of the lower mold 2 is provided with two symmetrical extrusion grooves 3, and the interior of the lower mold 2 is set There is a quality assurance mechanism 4 that assists the complete forming of the metal sheet. The upper mold 1 is equipped with a pressure detection mechanism 5 that monitors the force of the extrusion of the upper mold 1 and the lower mold 2. The pressure detection mechanism 5 includes detecting the pair of upper mold 1 and the lower mold. The excessive pressure induction component 51 of the excessive extrusion force of the mold 2 and the conductive limiting assembly 52 of limiting the downward pressure of the upper mold 1 when the extrusion force of the upper mold 1 to the lower mold 2 is too large.

[0032] The excessive pressure sensing component 51 includes a liquid tank 511, the liquid tank 511 is ...

Embodiment 3

[0038] see Figure 1-5 , an intelligent pressure detection device for stamping metal products, including an upper mold 1 and a lower mold 2, two symmetrical extrusion grooves 3 are opened on the surface of the lower mold 2, and auxiliary metal plates are arranged inside the lower mold 2 Fully formed quality assurance mechanism4.

[0039] The specifications of the upper mold 1 match the specifications of the lower mold 2, the specifications of the extrusion groove 3 match the specifications of the forming rod 6, a coil spring with a rotary reset function is arranged between the forming rod 6 and the upper mold 1, and the quality preservation mechanism 4 includes extrusion rod 41, which is fixedly connected to the outside of the upper mold 1 and slidingly connected to the lower mold 2, the piston 42 is fixedly connected to the bottom of the extrusion rod 41, and the check valve 43 is movably connected to the inside of the piston 42 , the air groove 44 is arranged in the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com