Bran modification method and gluten-containing flour product

A bran modification technology, applied in the bran modification method and the field of gluten-containing flour products, can solve the problems of low proportion of soluble dietary fiber, poor texture and taste, small size of flour products, etc., to overcome rough taste, Easy to dry, overcome the effect of high moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

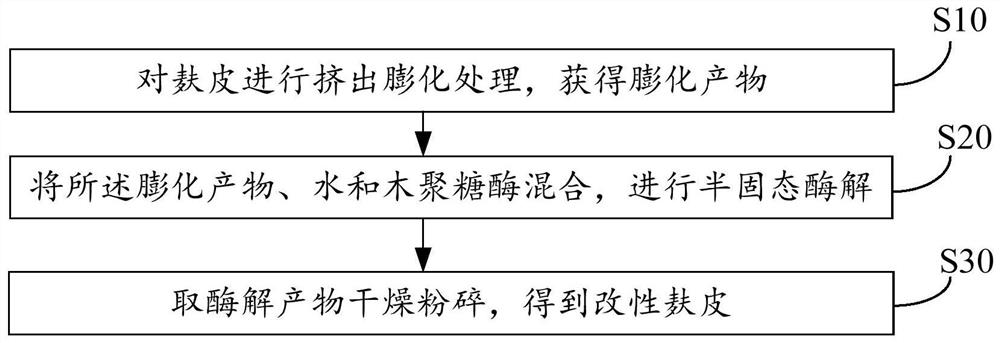

Method used

Image

Examples

Embodiment 1

[0044] The temperature of the twin-screw extruder is set to 60°C, 90°C, 120°C, 140°C, 130°C (outlet temperature) in sequence along the material conveying direction. Take by weighing 1000g of wheat bran, join in extruder and extrude and puff.

[0045] Take the puffed product at the discharge port, and mix it with 1000ml water and 10 6 U xylanase was mixed evenly, and hydrolyzed at 50° C. for 4 hours to obtain the hydrolyzed product.

[0046] Dry the enzymolyzed product at 105°C for 40 minutes to inactivate the enzyme in the product; continue drying at 50°C until the water content is 5% to 7% (mass fraction, wt%); then dry the product The dry product is pulverized and passed through a 60-mesh sieve to obtain modified bran, and the ratio of soluble dietary fiber in the total fiber in the modified bran is 12.3%.

Embodiment 2

[0048] The temperature of the twin-screw extruder is set to 60°C, 90°C, 120°C, 140°C, 130°C (outlet temperature) in sequence along the material conveying direction. Take by weighing 1000g of wheat bran, join in extruder and extrude and puff.

[0049] Take the puffed product at the discharge port, and mix it with 1000ml water and 10 6 U xylanase was mixed evenly, and hydrolyzed at 50° C. for 4 hours to obtain the hydrolyzed product.

[0050] Dry the enzymatic hydrolysis product at 105°C for 45 minutes to inactivate the enzyme in the product; continue drying at 45°C until the water content is 5% to 7% (mass fraction, wt%); then dry the product The dry product is pulverized and passed through a 60-mesh sieve to obtain modified bran, and the ratio of soluble dietary fiber in the total fiber in the modified bran is 11.9%.

Embodiment 3

[0052] The temperature of the twin-screw extruder is set to 60°C, 90°C, 120°C, 140°C, 130°C (outlet temperature) in sequence along the material conveying direction. Take by weighing 1000g of wheat bran, join in extruder and extrude and puff.

[0053] Take the puffed product at the discharge port, and mix it with 1000ml water and 10 6 U xylanase was mixed evenly, and hydrolyzed at 50° C. for 4 hours to obtain the hydrolyzed product.

[0054] Dry the enzymatic hydrolysis product at 100°C for 40 minutes to inactivate the enzyme in the product; continue drying at 50°C until the water content is 5% to 7% (mass fraction, wt%); then dry the product The dry product is pulverized and passed through a 60-mesh sieve to obtain modified bran, and the ratio of soluble dietary fiber in the total fiber in the modified bran is 11.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com