NiPd/Ni anchored nitrogen-doped carbon nanosheet composite material, and preparation method and application thereof

A technology of nitrogen-doped carbon and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the insufficient performance of bifunctional oxygen electrocatalysis, hinder the performance of zinc-air batteries, and scarcity issues such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the present invention comprises the following steps:

[0043] (1) Prepare Ni at 80-200°C by solvothermal method 2+ / Pd 2+ / iminodiacetonitrile nanosheet complex;

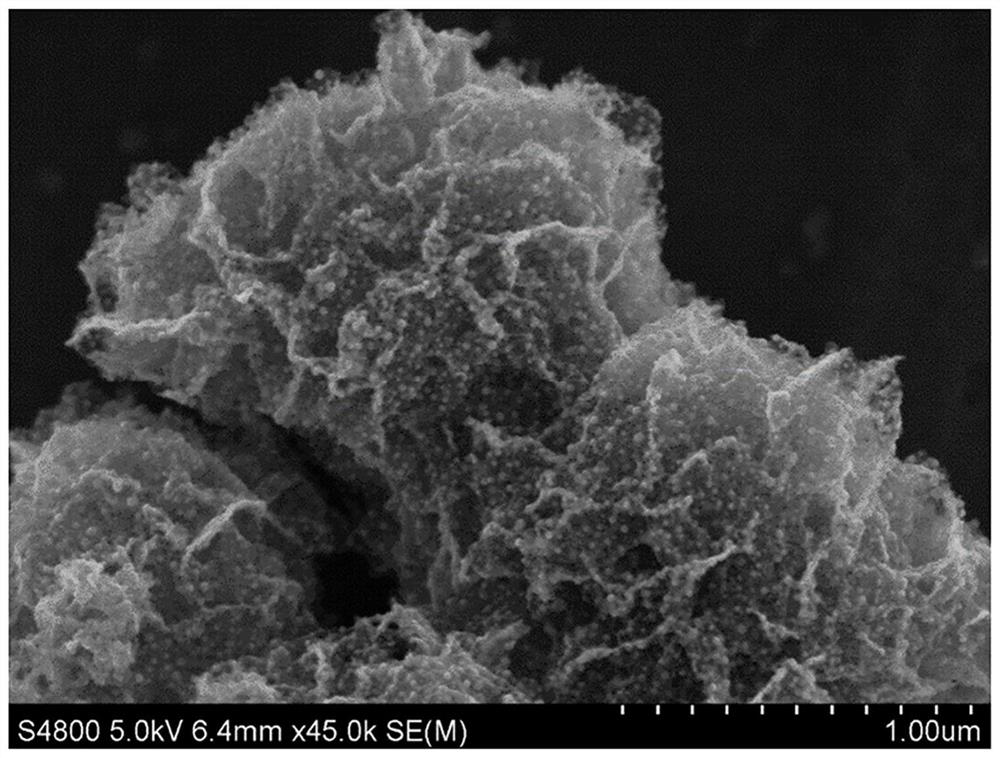

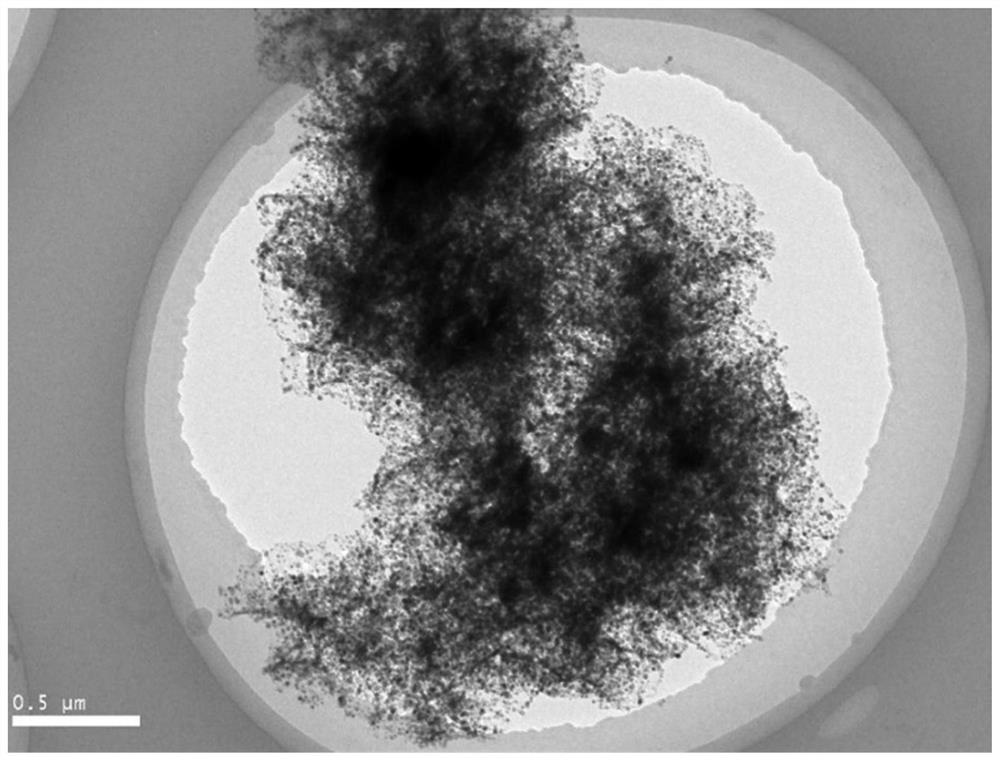

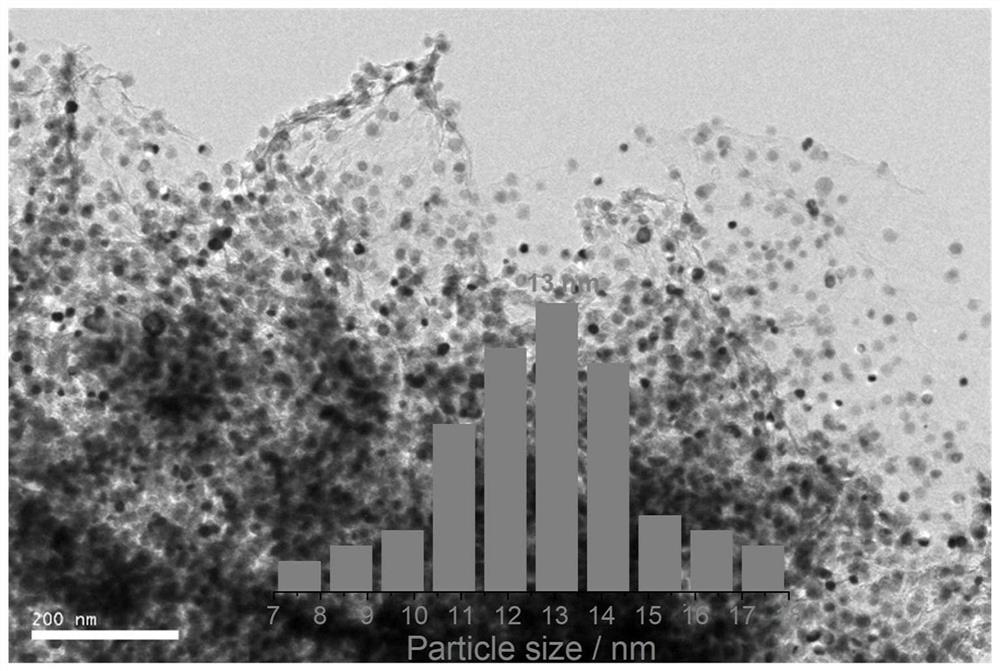

[0044] (2) the Ni 2+ / Pd 2+ / Iminodiacetonitrile nano-sheet complex is heat-treated for a period of time in an inert / reducing atmosphere at 600-800° C. through temperature programming to obtain nitrogen-doped carbon nano-sheets anchored by NiPd / Ni; Nitrogen-doped carbon nanosheet composites loaded with NiPd alloy and Ni elemental substance.

Embodiment 1

[0046] A preparation method for anchoring NiPd / Ni nitrogen-doped carbon nanosheet composite material, comprising the following steps:

[0047] 1)Ni 2+ / Pd 2+ Preparation of iminodiacetonitrile nanosheet complex: weigh 60mg Ni(acac) 2 with 7.1mgPd(acac) 2 and 150 mg of iminodiacetonitrile (the molar ratio of nickel compound / palladium compound / iminodiacetonitrile is 10:1:67) was added to a reaction kettle containing 30 mL of benzyl alcohol; mechanically stirred and ultrasonicated for 6 h at room temperature , so that the solids are completely dissolved and mixed evenly; then put the dissolved solution reactor into an oven for reaction at 140°C for 6 hours, after cooling to room temperature, the obtained product is washed with ethanol several times and dried to obtain Ni 2+ / Pd 2+ / iminodiacetonitrile nanosheet complex;

[0048] 2) Preparation of nitrogen-doped carbon nanosheet composite anchoring NiPd / Ni: the khaki Ni obtained in step 1) 2+ / Pd 2+ / iminodiacetonitrile na...

Embodiment 2

[0051] A preparation method for anchoring NiPd / Ni nitrogen-doped carbon nanosheet composite material, comprising the following steps:

[0052] 1) 1) Ni 2+ / Pd 2+ Preparation of iminodiacetonitrile nanosheet complex: weigh 60mg Ni(acac) 2 with 14.2mg Pd(acac) 2 and 150mg of iminodiacetonitrile (the molar ratio of nickel compound / palladium compound / iminodiacetonitrile is 10:2:67) was added to a reaction kettle containing 30mL of benzyl alcohol; mechanically stirred and ultrasonicated for 6h at room temperature , so that the solids are completely dissolved and mixed uniformly; then put the dissolved solution reactor into an oven for reaction at 140°C for 6 hours, after cooling to room temperature, the obtained product is washed with ethanol several times and dried to obtain Ni 2+ / Pd 2+ / iminodiacetonitrile nanosheet complex;

[0053] 2) Preparation of nitrogen-doped carbon nanosheet composite anchoring NiPd / Ni: the khaki Ni obtained in step 1) 2+ / Pd 2+ / iminodiacetonitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com