Method for testing function reliability of charging equipment

A test method and technology for charging equipment, which are applied in environmental/reliability testing, climate sustainability, electric vehicle charging technology, etc., can solve the problems of easy accumulation of dust on graphics processing modules, damage to graphics processing modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] A method for testing the functional reliability of a charging device, comprising the following steps:

[0040] S1, using a finite state machine (FSM) to generate a formalized model;

[0041] S2. Use the graphical description SDL / GR to list the formal description;

[0042] S3. Generating functional test items from the FSM formal model and formal description.

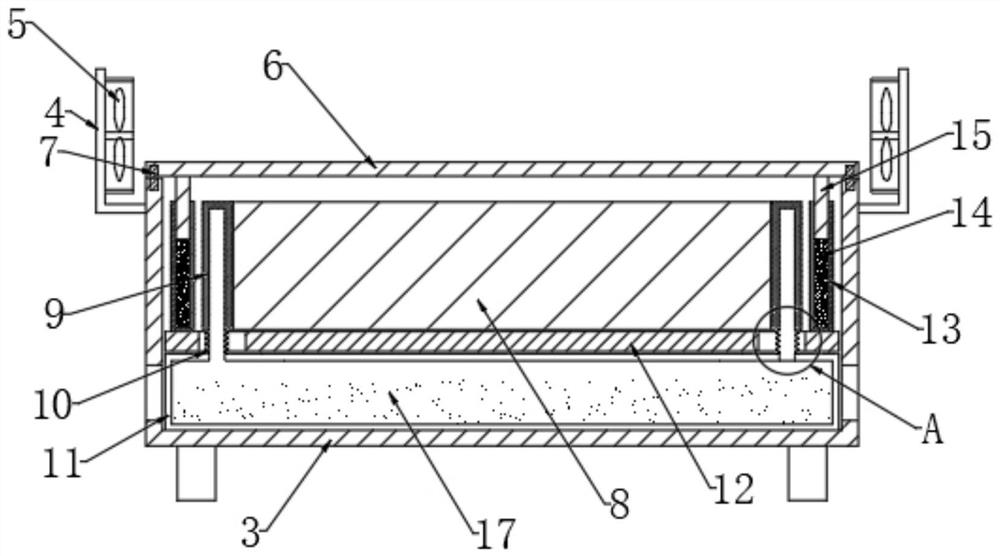

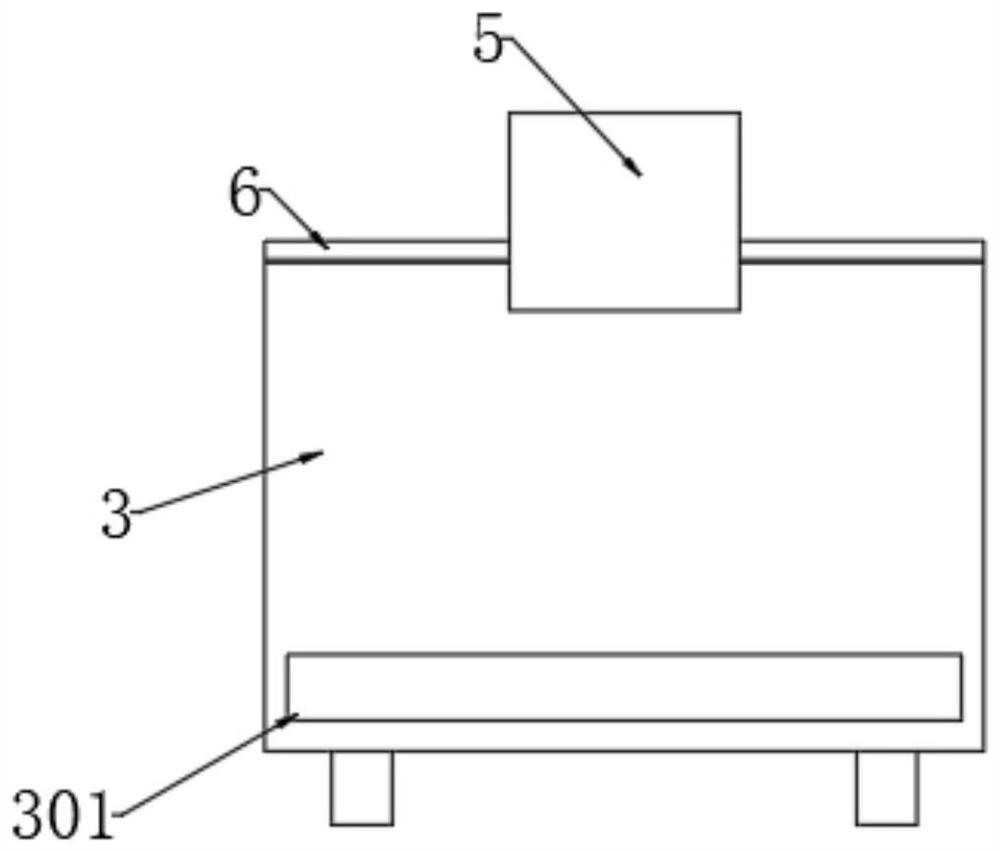

[0043] see Figure 1-2 , the graphical description in S2 includes a charging pile 1 and a graphics processing module 8, a control processor 2 is fixedly installed on one side of the charging pile 1, a protective casing 3 is fixedly installed on the bottom of the charging pile 1, and the two sides of the protective casing 3 are set There is a connecting block 4, a fan 5 is installed on one side of the connecting block 4, a protective plate 6 is provided on the upper surface of the protective shell 3, and an infrared sensor 7 is arranged on the lower surface of the protective plate 6 and the upper wall of the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com