High-temperature-resistant fusing electrode convenient in sample replacement

A high temperature resistant, electrode technology, applied in thermometers, using electrical devices, using electromagnetic means, etc., can solve problems that affect application, repeatability, poor reliability, and affect instrument accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

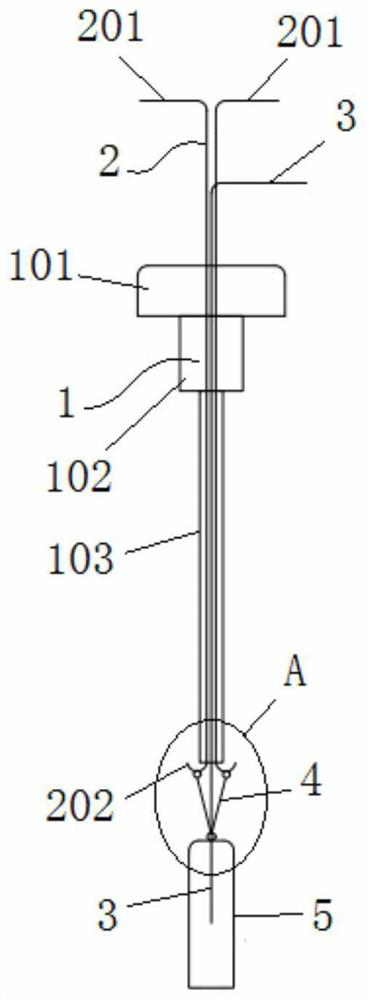

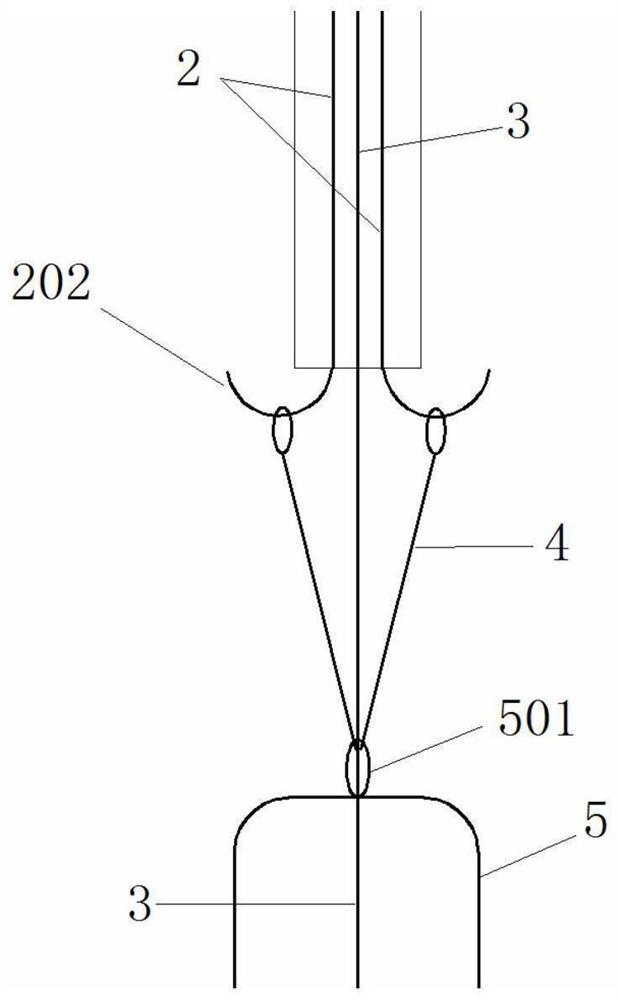

[0022] Such as Figure 1~3 As shown, the present invention includes an electrode housing 1, an electrode wire 2, a thermocouple 3, a fuse 4 and a sample cell 5, two electrode wires 2 run through the electrode housing 1 and electrode hooks 202 are formed at the lower ends, and the fuse 4 The two ends are respectively hung on the electrode hook 202 on the corresponding side, the sample pool 5 is hung on the fuse 4, the thermocouple 3 runs through the electrode housing 1 and the lower end is inserted into the sample pool 5, the electrode An electrode plug 102 is provided at the upper end of the casing 1 .

[0023] Such as figure 1 and image 3 As shown, the electrode housing 1 includes an electrode plug 102 and an electrode rod 103, wherein an electrode cap 101 is provided on the upper side of the electrode plug 102, and a through hole is provided in the midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com