Building material kiln roasting system based on big data and process thereof

A big data and big data platform technology, applied in the field of kiln roasting, can solve the problems of lower production efficiency, kiln brick bursting, frosting or blackhead bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

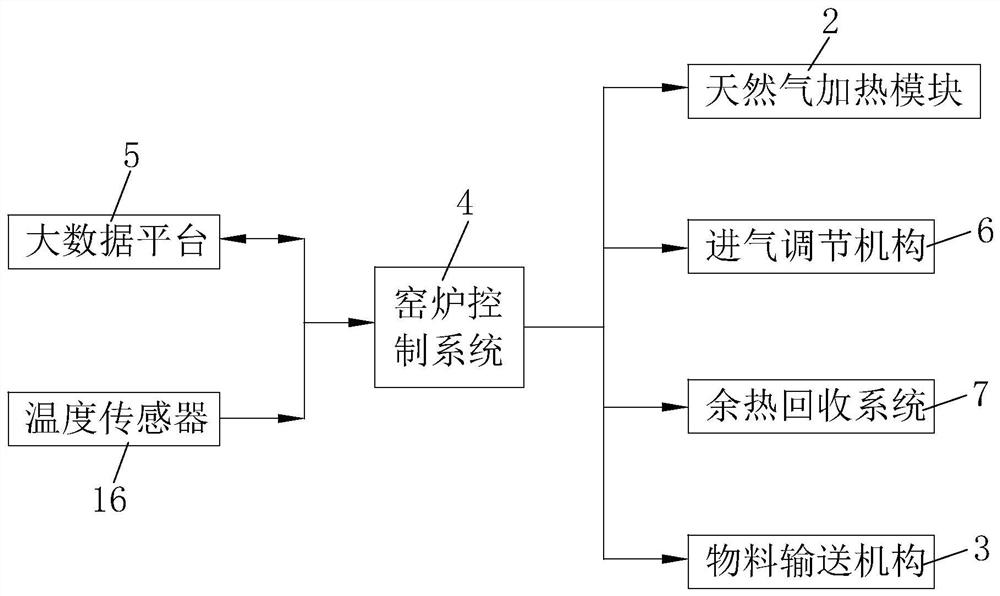

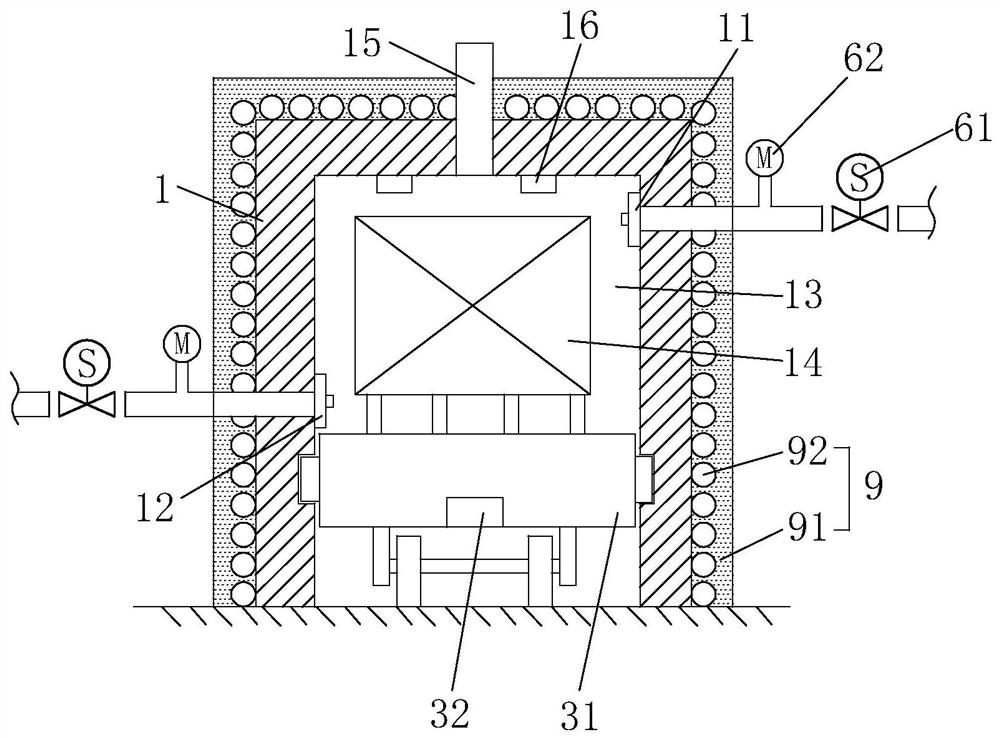

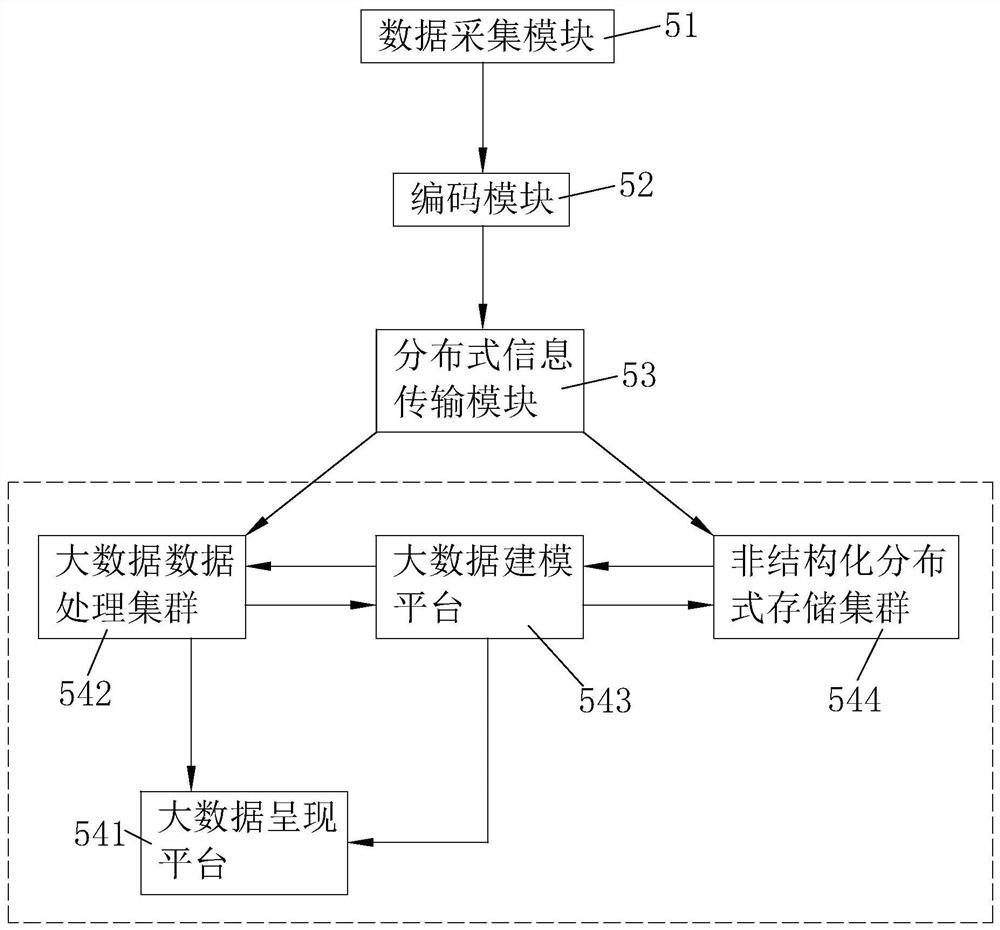

[0037] refer to figure 1 , is a big data-based building material kiln roasting system disclosed in the present invention, including a kiln body 1, a natural gas heating module 2, a material delivery mechanism 3, a kiln control system 4, and a big data platform 5, an air intake adjustment mechanism 6 and the waste heat recovery system 7, the kiln control system 4 is connected to the big data platform 5 through the Internet, the kiln control system 4 is respectively connected to the natural gas heating module 2 and the material delivery mechanism 3, and the material delivery mechanism 3 is slidingly arranged on the kiln body 1 It is used to pass the production products through the preheating zone, firing zone and cooling zone of the tunnel kiln in sequence. The big data platform 5 is used to store the distributed unstructured storage of the actual production da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com