Energy-saving coal mine large-batch mining equipment and method thereof

A large-volume, energy-saving technology, applied in open-pit mining, chemical instruments and methods, ground mining, etc., can solve problems such as large coverage area, small mining volume, and reduced mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

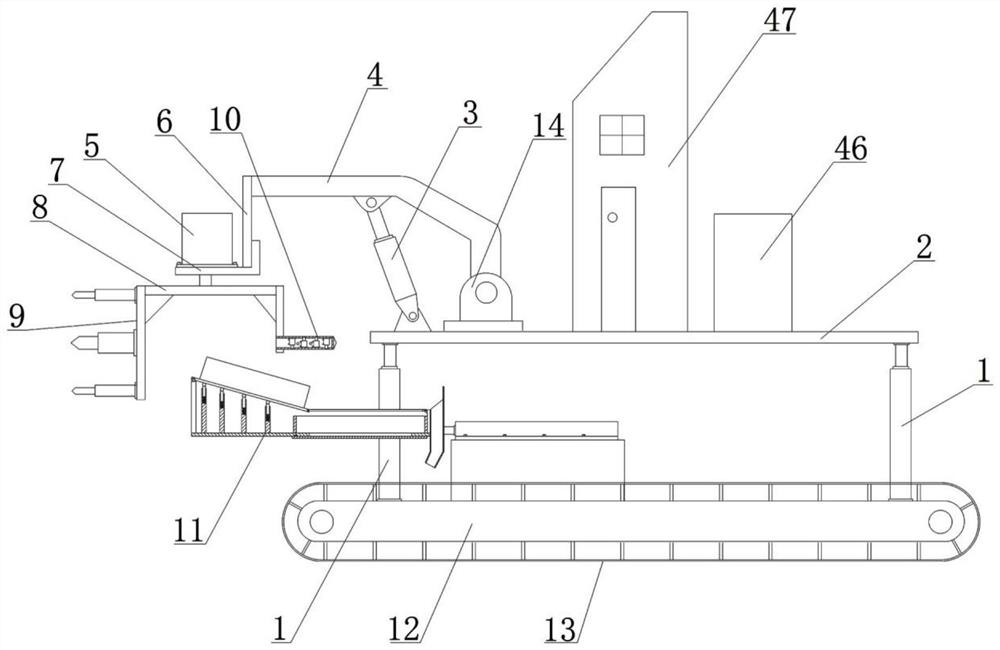

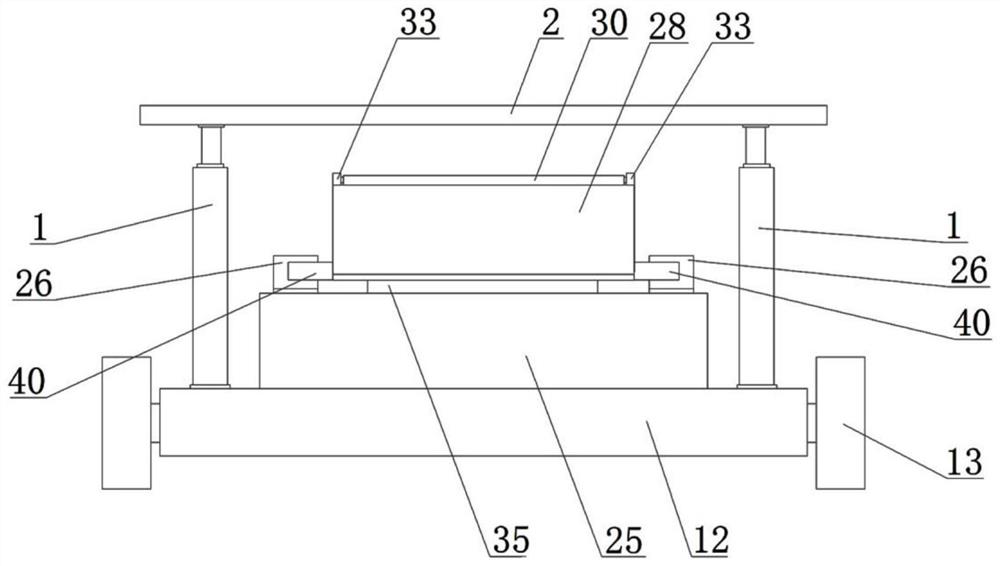

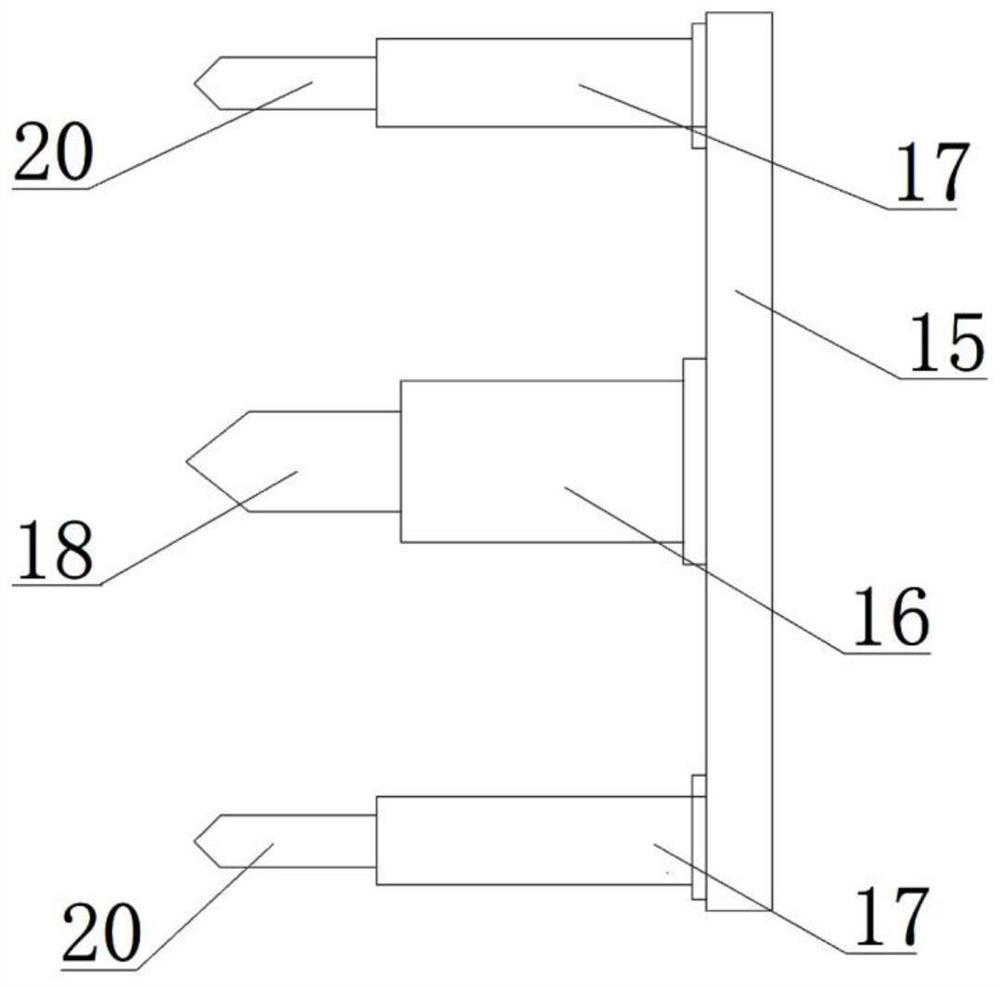

[0041] like Figure 1-9 Shown, a kind of energy-saving type coal mine large-scale mining equipment, it comprises traveling mechanism, and traveling mechanism comprises chassis 12 and crawler belt 13 that is respectively installed on chassis 12 front and rear sides, and the chassis 12 of described traveling mechanism is positioned at its four corners Both are fixed with a lifting cylinder 1, and a lifting plate 2 is fixed on the plane formed by the piston rod of the lifting cylinder 1, and a feed swing arm mechanism is also arranged on the lift plate 2, and the feed swing arm mechanism includes a pitch cylinder 3, Swing arm 4 and hydraulic motor 5, one end of said swing arm 4 is hinged on the top surface of lifting plate 2, and the other end extends to the outside of lifting plate 2 to the left, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com