Coal Mining Method without Coal Pillar in the Whole Mining Area and No Roadway Tunneling

A coal mining method and roadway technology, applied in mining equipment, tunnels, ground mining, etc., can solve the problems of waste of coal resources, high excavation costs, long excavation time, etc., to save time and money, eliminate excavation, and improve recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

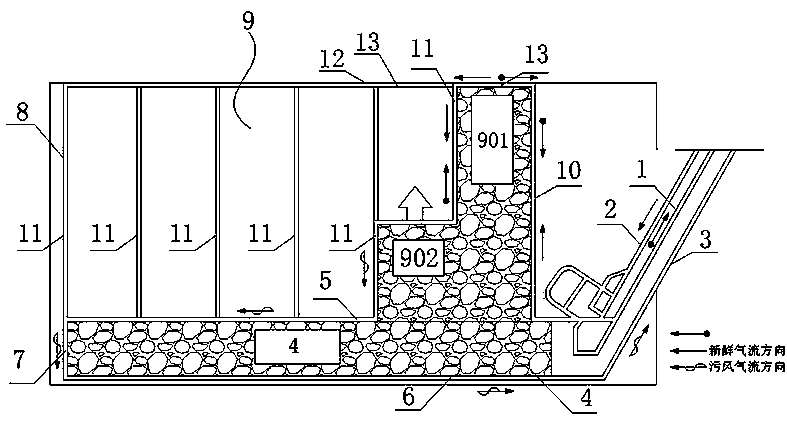

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

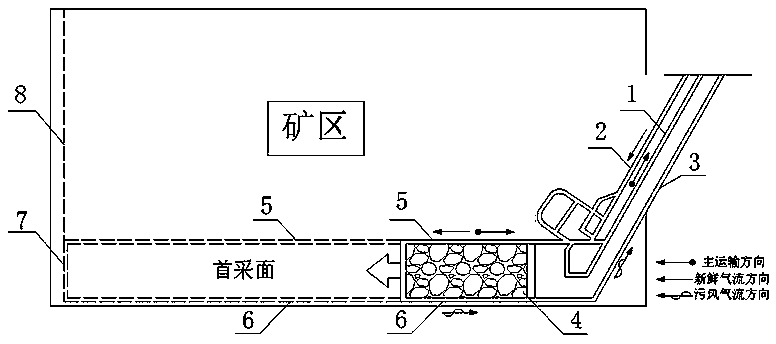

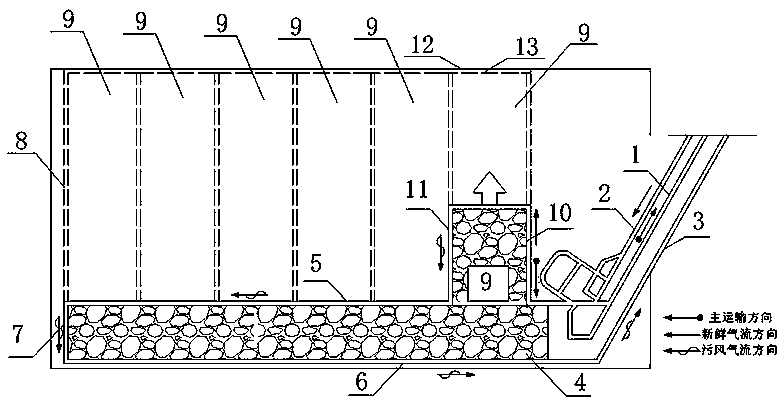

[0032] see figure 1 As shown, according to the embodiment of the present invention, there is provided a coal mining method without coal pillars in the whole mining area without roadway excavation, and the coal mining method includes the following steps:

[0033] Open the main shaft 1, auxiliary shaft 2 and return air shaft 3 from the ground to the coal seam;

[0034] After the main shaft 1, the auxiliary shaft 2 and the air return shaft 3 are opened to the coal mining seam, a working face production system is arranged on the coal mining seam;

[0035] Excavating the coal wall by cutting the coal wall in the first direction with the shearer, and forming the first mining face 4 with the first direction as the traveling direction;

[0036] When the shearer cuts the coal wall at the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com