Mineral separation device for producing phosphorite through microalgae phosphorus accumulation

A phosphate rock and microalgae technology, applied in mixers with rotating stirring devices, flotation, dissolution, etc., can solve the problem of low phosphate rock beneficiation efficiency, shorten the mineral processing time, enhance foam fluidity, increase The effect of large catalytic area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

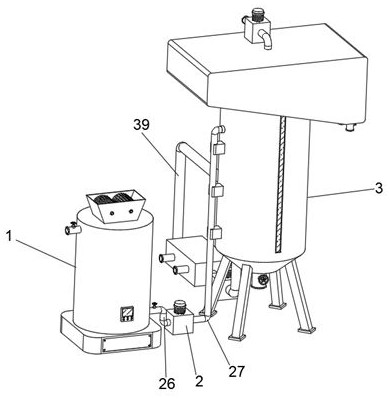

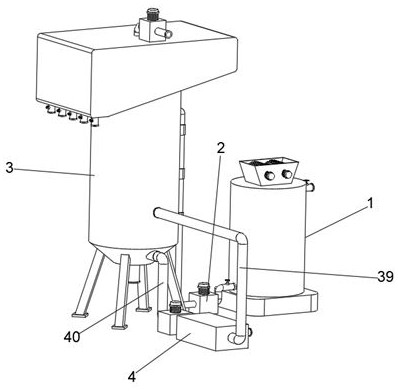

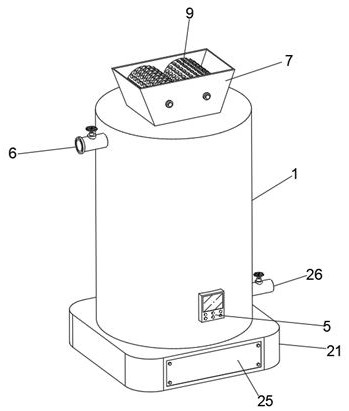

[0031] Example: see Figure 1-2 , a beneficiation device for producing phosphate ore by microalgae phosphorus accumulation, comprising a pulp cylinder 1, a first pump 2, a flotation tower 3 and a foaming mechanism 4, characterized in that: the bottom of the pulp cylinder 1 is provided with a fixed base 21, the second The bottom end of the second transmission shaft 10 is rotationally connected with the inner bottom of the fixed base 21, the second transmission shaft 10 is fixedly sleeved with a driven gear 22, the right side of the inner bottom of the fixed base 21 is fixedly connected with a drive motor 23, and the output end of the drive motor 23 is fixed. The driving gear 24 is connected, and the driving gear 24 is meshed with the driven gear 22. A slurry outlet pipe 26 is fixedly connected between the slurry cylinder 1 and the input end of the first pump machine 2. The flotation tower 3 is connected to the output end of the first pump machine 2. A slurry pipe 27 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com