Microorganism-photoelectrochemistry-thermoelectrochemistry coupling hydrogen production system

A photoelectrochemical and thermoelectrochemical technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of low utilization rate of light energy conversion, anode deactivation, inhibition of anode biofilm activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific technical solutions of the present invention will be described in connection with the examples.

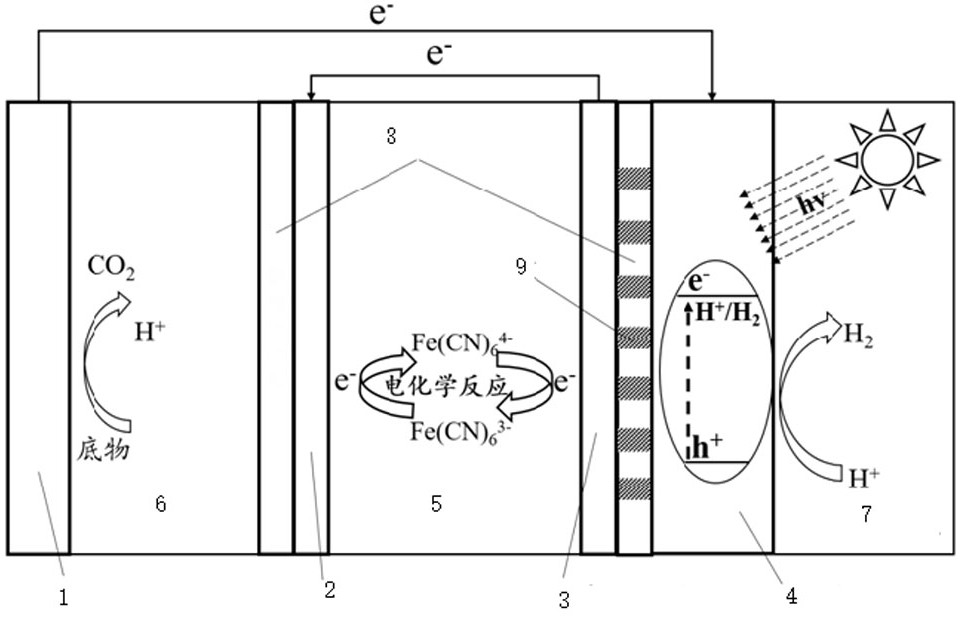

[0024] like figure 1 As shown, the microbial-photochemical-thermochemical coupling hydrogen hydrogen hydrophilic chemical coupling system of the present invention includes a microbial anode 1, a photovoltaic pole 4, a heat chemical cell. The thermochemical cell and the microbial anode 1 are separated from ion exchange membranes 8, and the microbial anode 1 and the optical cathode 4 are connected to the external circuitry and apparatus via a wire.

[0025] The system photocathode 4 side uses a transparent quartz glass and other materials such that the sunlight can be effectively irradiated to the surface of the electrode; the photocathode 4 is connected to the thermochemical battery anode 3, so that the photocathode 4 heat is efficiently transmitted to the heat chemical cell. Anode 3.

[0026] There is an anode electrolyte 6 in the microbial anode 1, and there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com