Polyurethane waterproof coating and preparation method thereof, and two-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and coating technology, applied in the field of polyurethane waterproof coating and its preparation, two-component polyurethane waterproof coating and its preparation, can solve problems such as not being able to meet multi-functional use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

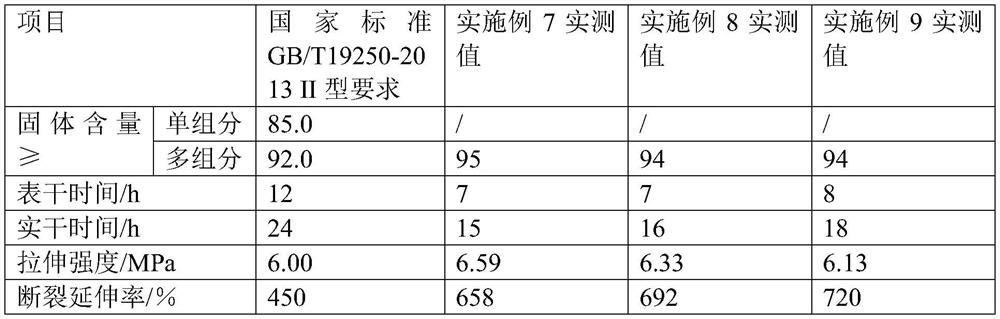

Examples

Embodiment 1

[0022] A kind of polyurethane waterproof coating of the present application, comprises the component of following parts by weight:

[0023] 5 parts of plasticizer, 5 parts of filler oil, 20 parts of polyether polyol A, 10 parts of polyether polyol C, 10 parts of diphenylmethane diisocyanate, 20 parts of 800 mesh heavy calcium, 25 parts of 600 mesh talcum powder, 400 mesh 15 parts of heavy calcium, 0.1 part of defoamer, 0.1 part of dispersant, 0.1 part of catalyst, 4 parts of solvent naphtha, 0.5 part of curing agent; wherein, the number average molecular weight of polyether polyol A is 3000 Da, and that of polyether polyol C The number average molecular weight is 1000 Da.

Embodiment 2

[0025] A kind of polyurethane waterproof coating of the present application, comprises the component of following parts by weight:

[0026] 7 parts of plasticizer, 7 parts of filler oil, 23 parts of polyether polyol A, 7 parts of polyether polyol C, 7 parts of diphenylmethane diisocyanate, 17 parts of 800 mesh heavy calcium, 23 parts of 600 mesh talcum powder, 400 mesh 13 parts of heavy calcium, 0.6 part of defoamer, 0.6 part of dispersant, 0.6 part of catalyst, 6 parts of solvent oil, and 0.7 part of curing agent; wherein, the number average molecular weight of polyether polyol A is 4000 Da, and that of polyether polyol C The number average molecular weight is 2000 Da.

Embodiment 3

[0028] A kind of polyurethane waterproof coating of the present application, comprises the component of following parts by weight:

[0029] 10 parts of plasticizer, 10 parts of filler oil, 25 parts of polyether polyol A, 5 parts of polyether polyol C, 5 parts of diphenylmethane diisocyanate, 15 parts of 800 mesh heavy calcium, 20 parts of 600 mesh talcum powder, 400 mesh 10 parts of heavy calcium, 1 part of defoamer, 1 part of dispersant, 1 part of catalyst, 8 parts of solvent oil, and 1 part of curing agent; wherein, the number average molecular weight of polyether polyol A is 6000 Da, and that of polyether polyol C The number average molecular weight is 3000 Da.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com