Triazine covalent organic framework material rich in allyloxy as well as preparation method and application of triazine covalent organic framework material

A covalent organic framework and allyloxy technology, which is applied in the preparation of triazine covalent organic framework and the application field of lithium-sulfur battery cathode materials, can solve the problems of lack of research and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

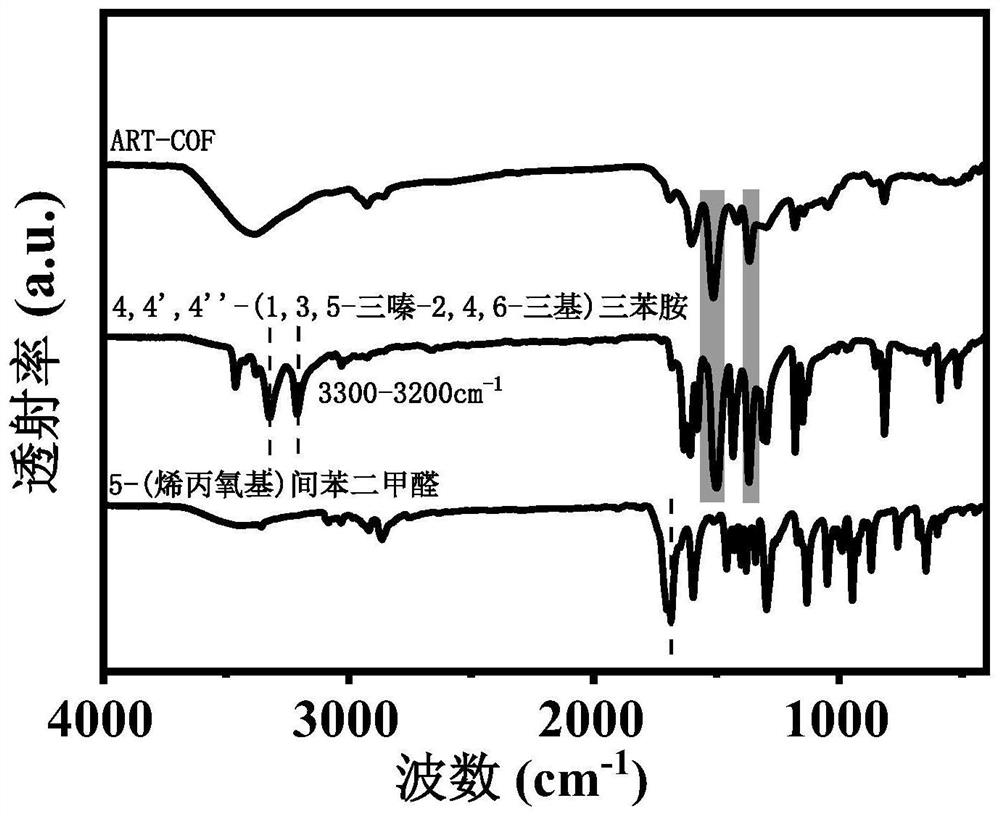

Embodiment 1

[0035] (1) Preparation of allyloxy-triazine covalent organic framework material: 142 mg (ie 0.75 mmol) of 5-(allyloxy) isophthalaldehyde and 177 mg (ie 0.5 mmol) of 4,4 ',4"-(1,3,5-triazine-2,4,6-triyl)triphenylamine was placed in a 100ml thick-walled pressure bottle, vacuumed, filled with argon, and 60ml of 1,4 - Dioxane, 12 ml 1,3,5-trimethylbenzene and 5 ml glacial acetic acid, sonicated for 5 minutes to fully dissolve, three cycles of liquid nitrogen freezing (each cycle including "freeze-thaw" Steps, the freezing is freezing at liquid nitrogen -196°C for 5 minutes, thawing is standing for 15 minutes under natural conditions and returning to room temperature), filling with argon, heating to 120°C in an oil bath, and constant temperature reaction for 3 day, cooled, filtered, the solid was repeatedly washed with absolute ethanol, and washed with acetone for 24 hours, and dried in vacuum at 60°C for 6 hours to obtain the covalent organic framework ART-COF, the infrared spectr...

Embodiment 2

[0045] Other steps are the same as in Example 1, except that the constant temperature reaction time is replaced by 5 days by 3 days.

Embodiment 3

[0047] Other steps are the same as in Example 1, except that 150 mg of sublimed sulfur powder is replaced by 175 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com