Positioning clamping device suitable for machining single-head screw pump rotor

A positioning and clamping, single-head screw technology, applied in the field of tooling and fixtures, can solve problems such as affecting the machining accuracy of workpieces, changing diameters, and unable to achieve stable workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

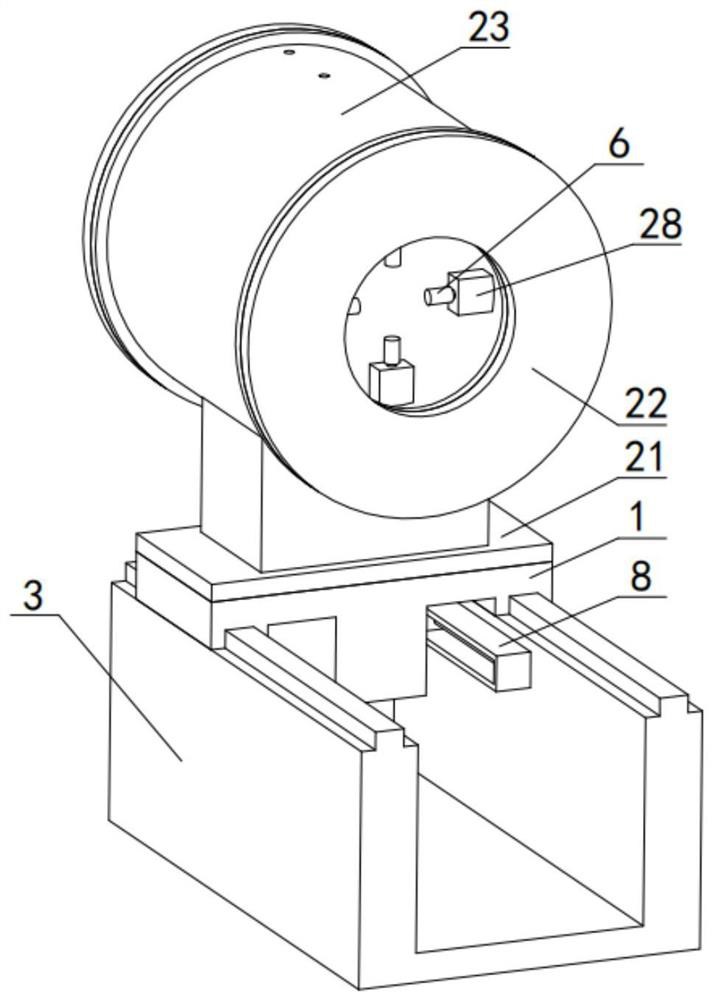

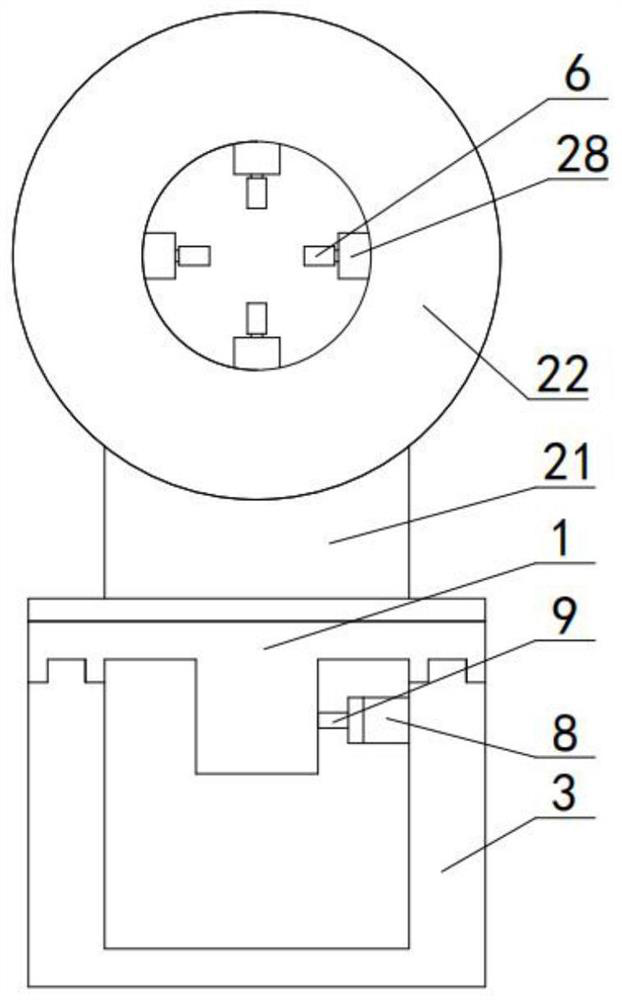

[0031] refer to figure 1 As shown, the present invention discloses a positioning and clamping device suitable for processing single-head screw pump rotors, including:

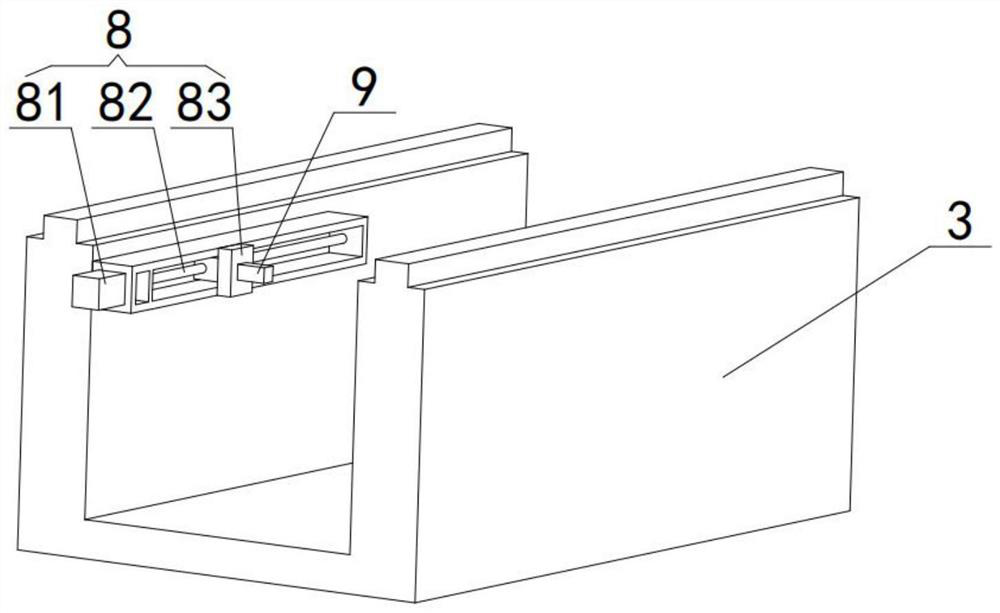

[0033] A workbench 1; the workbench 1 is slidably arranged on guide rails on both sides of the machine bed body 3;

[0034] Clamping mechanism 2; Clamping mechanism 2 comprises base 21, 2 seal covers 22, outer casing 23, inner casing 24, piston plate 25, sealing plate 26, drive plate 27 and 4 claws 28; The bottom of base 21 The end is fixedly connected to the top of the workbench 1; the outer shell 23 is fixedly connected to the upper end of the base 21, and its two ends are symmetrically arranged along the middle part of the base 21; two sealing covers 22 are respectively fixedly connected to the front and rear sides of the outer shell 23 end; the inner shell 24 is sleeved inside the outer shell 23, and it is coaxially arranged with the outer shell 23; A closed working chamber 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com