Scraping and planing device for matching surface machining during intelligent production of fitness equipment

A technology for intelligent production and fitness equipment, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as excessive debris, easy wear of scrapers, and inability to scrape scrapers against protective scrapers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

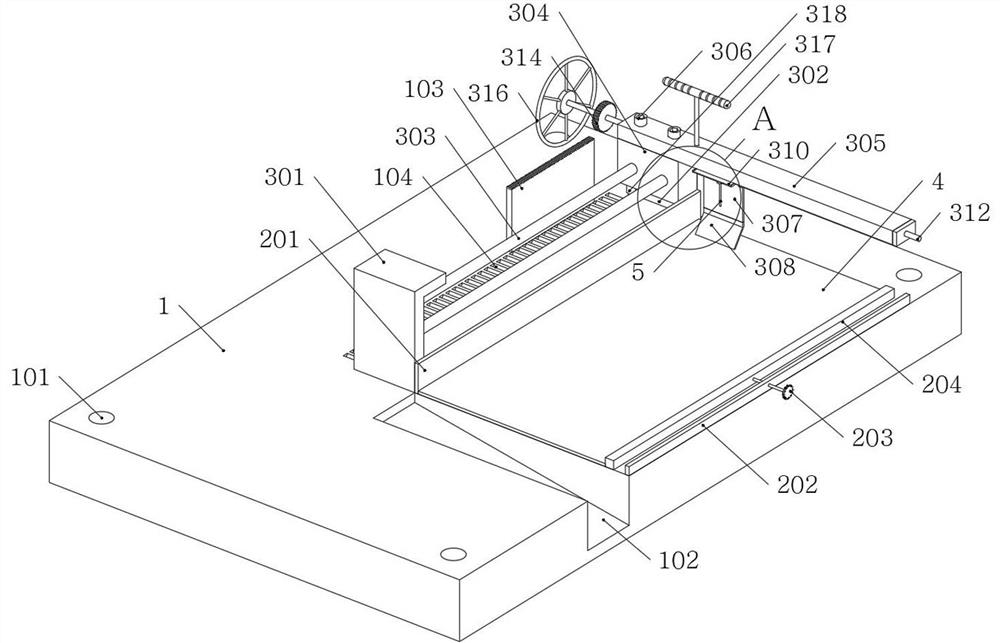

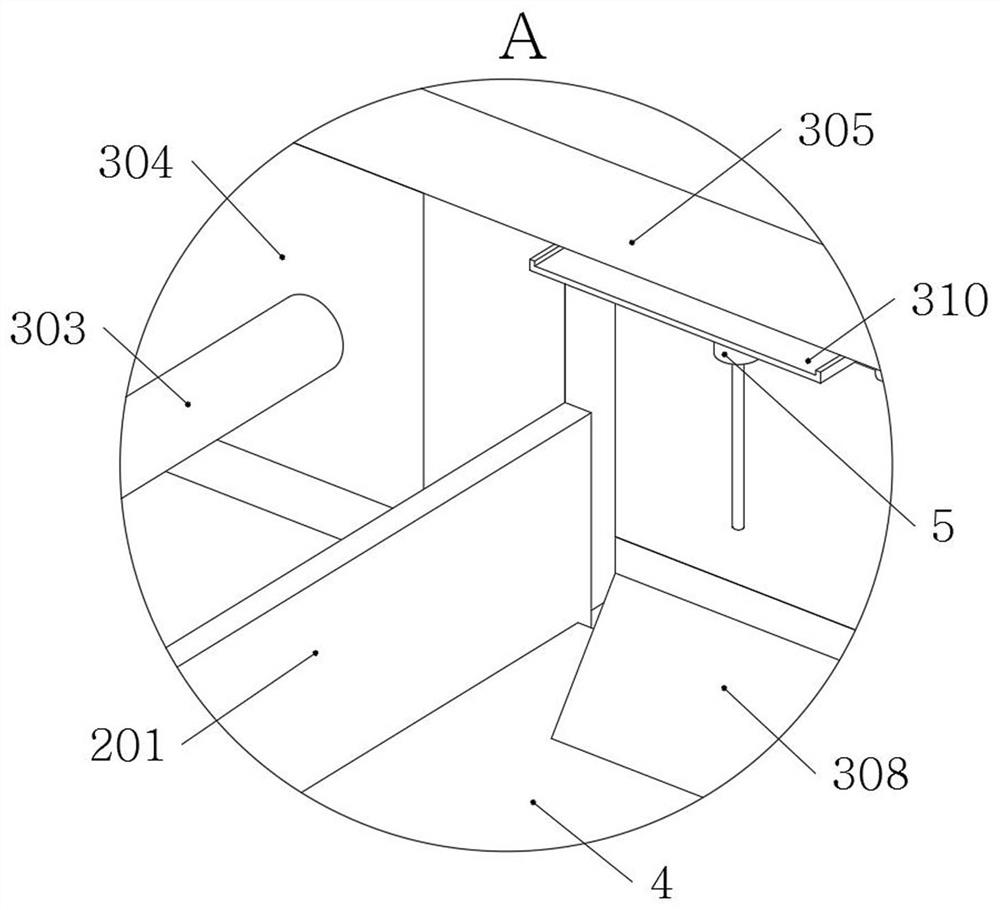

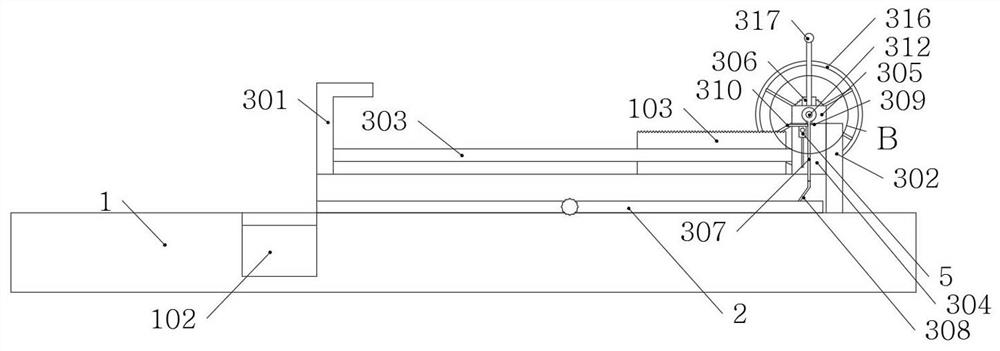

[0066] as attached figure 1 To attach Figure 10 Shown:

[0067] The invention provides a scraping device for processing mating surfaces for intelligent production of fitness equipment, including a main body seat 1; the main body seat 1 is a rectangular plate structure;

[0068] The fixed structure 2, the fixed structure 2 is installed on the main body seat 1, and the plate 4 is clamped on the fixed structure 2;

[0069] The scraping part 3, the scraping part 3 is installed on the main body seat 1, and the liquid bottle 5 is installed on the scraping part 3.

[0070] Reference as figure 1 , the main body seat 1 includes:

[0071] The tooth row 103, the tooth row 103 is welded on the top surface of the main body seat 1;

[0072] There are four fixing holes 101, and there are four fixing holes 101, and the four fixing holes 101 are all set on the main body seat 1;

[0073] Cleaning tank 102, the cleaning tank 102 is provided on the main body seat 1, and the bottom end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com