CdZnS superfine nanoparticle loaded In2O3 fusiform nanorod composite material, and preparation method and application thereof

A technology of ultra-fine nano and composite materials, which is applied in the field of photocatalyst material preparation and can solve problems such as instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

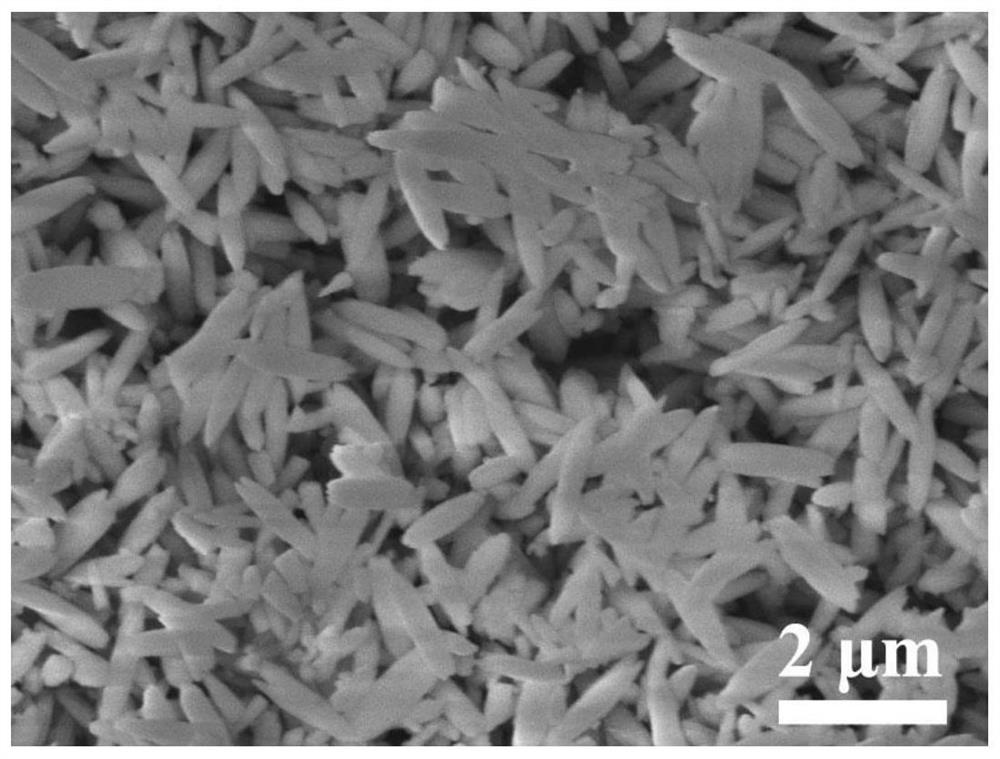

[0053] S1. Dissolve 60 mg of indium nitrate and 65 mg of 2-aminoterephthalic acid in a reaction flask, react in an oil bath at 120 °C for 0.5 h, take it out, clean it once with ethanol, dry it by centrifugation, and place it in a muffle furnace. Fusiform mesoporous In was obtained by calcination at 500 ℃ in air atmosphere 2 O 3 Nano stave;

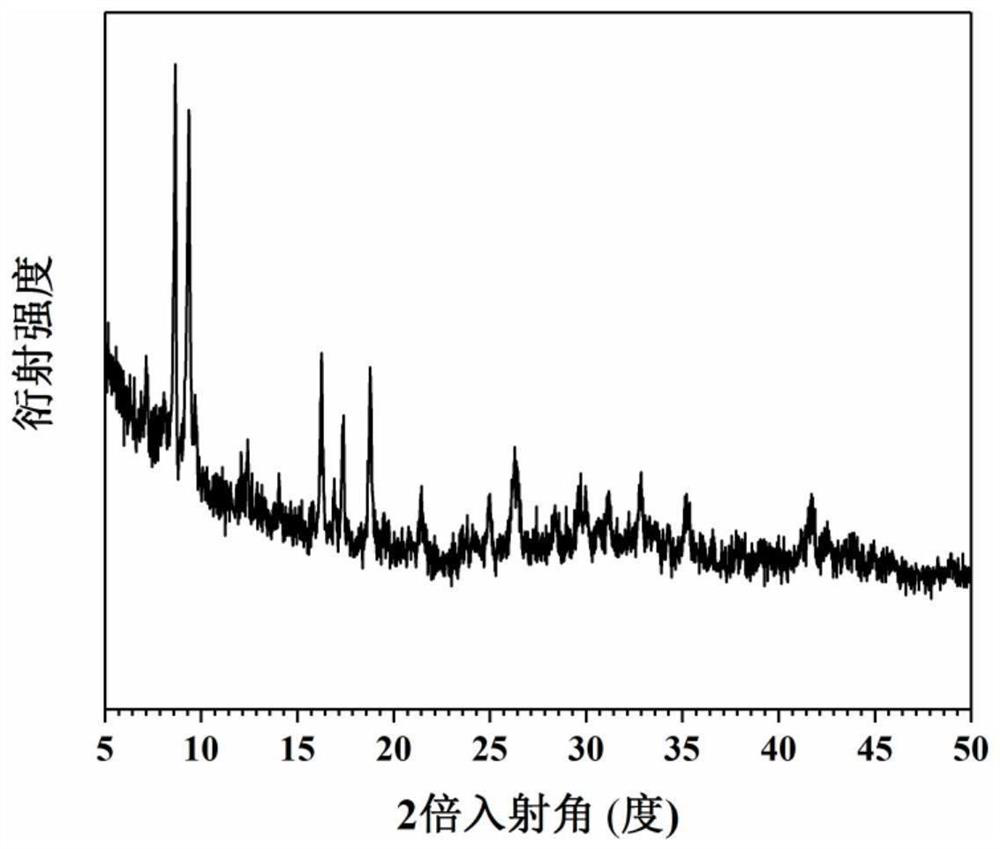

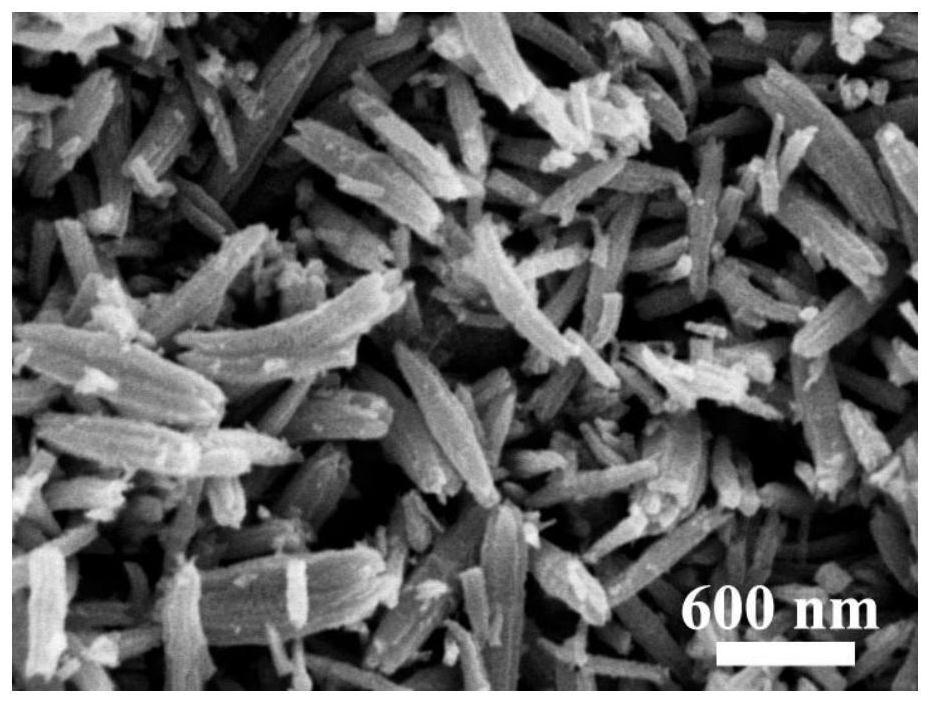

[0054] S2, take 20 mg of fusiform mesoporous In 2 O 3 The nanorods were mixed with 10 mg of cadmium acetate and 4.4 mg of zinc acetate, then immersed in 5 ml of deionized water, and then added with 20 mg of sodium sulfide, reacted in an oil bath at 80 °C for 2 h, taken out and cleaned with ethanol, and centrifuged and dried to obtain In 2 O 3 / CdZnS heterocomposite material, the loading of CdZnS ultrafine nanoparticles is 5wt%, the average particle size is 5nm, and the fusiform mesoporous In 2 O 3 The nanorods have an average diameter of 1 μm and an average pore size of 15 nm.

Embodiment 2

[0056] S1. Dissolve 60 mg of indium nitrate and 65 mg of 2-aminoterephthalic acid in a reaction flask, react in an oil bath at 120 °C for 0.5 h, take it out, clean it once with ethanol, dry it by centrifugation, and place it in a muffle furnace. Fusiform mesoporous In was obtained by calcination at 500 ℃ in air atmosphere 2 O 3 Nano stave;

[0057] S2, take 20 mg of fusiform mesoporous In 2 O 3 The nanorods were mixed with 15 mg of cadmium acetate and 8 mg of zinc acetate, then immersed in 5 ml of deionized water, and then added with 20 mg of sodium sulfide, reacted in an oil bath at 80 °C for 2 h, taken out and cleaned with ethanol, and centrifuged and dried to obtain In 2 O 3 / CdZnS heterocomposite material, the loading of CdZnS ultrafine nanoparticles is 8wt%, the average particle size is 5nm, and the fusiform mesoporous In 2 O 3 The nanorods have an average diameter of 1 μm and an average pore size of 15 nm.

Embodiment 3

[0059] S1. Dissolve 60 mg of indium nitrate and 65 mg of 2-aminoterephthalic acid in a reaction flask, react in an oil bath at 120 °C for 0.5 h, take it out, clean it once with ethanol, dry it by centrifugation, and place it in a muffle furnace. Fusiform mesoporous In was obtained by calcination at 500 ℃ in air atmosphere 2 O 3 Nano stave;

[0060] S2, take 20 mg of fusiform mesoporous In 2 O 3 The nanorods were mixed with 18 mg of cadmium acetate and 10 mg of zinc acetate, then immersed in 5 ml of deionized water, and then added with 20 mg of sodium sulfide, reacted in an oil bath at 80 °C for 2 h, taken out and cleaned with ethanol, and centrifuged and dried to obtain In 2 O 3 / CdZnS heterocomposite material, the loading of CdZnS ultrafine nanoparticles is 10wt%, the average particle size is 5nm, and the fusiform mesoporous In 2 O 3 The nanorods have an average diameter of 1 μm and an average pore size of 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com