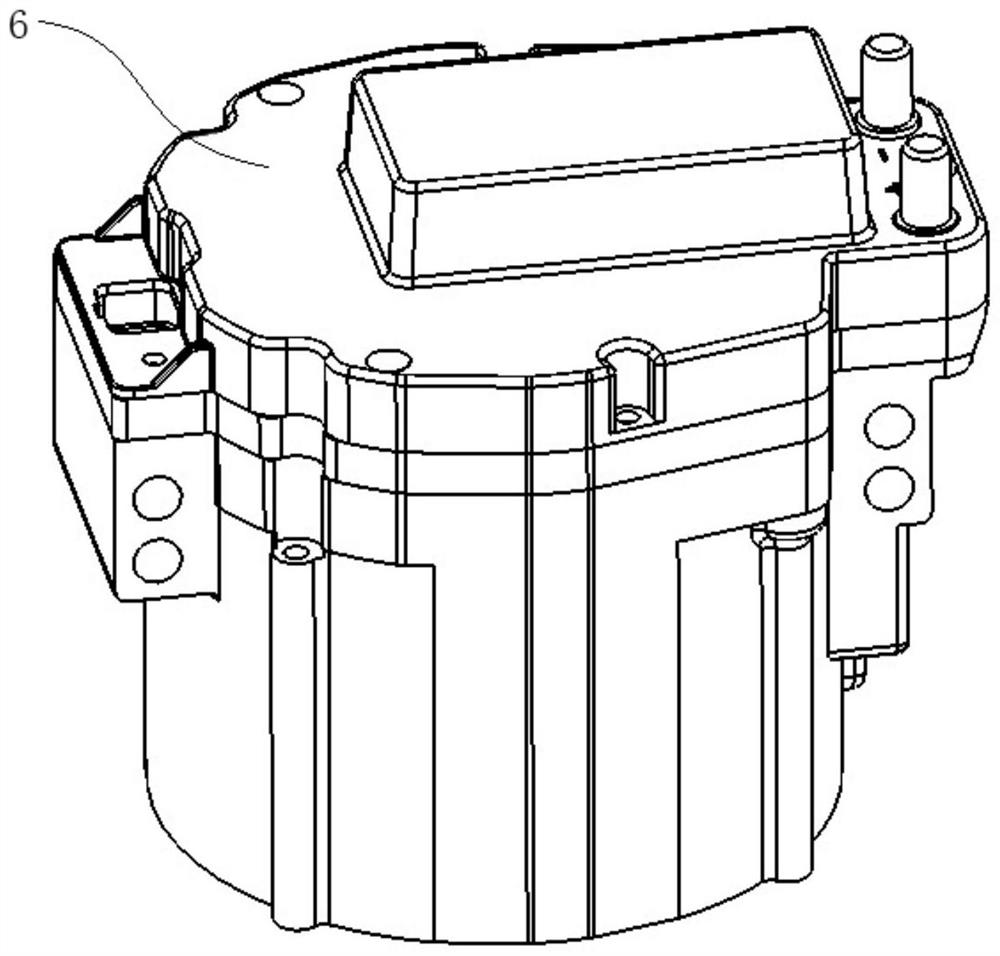

48V BSG motor integrated inverter

A BSG motor, integrated technology, applied in the direction of motors, capacitors, electrolytic capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

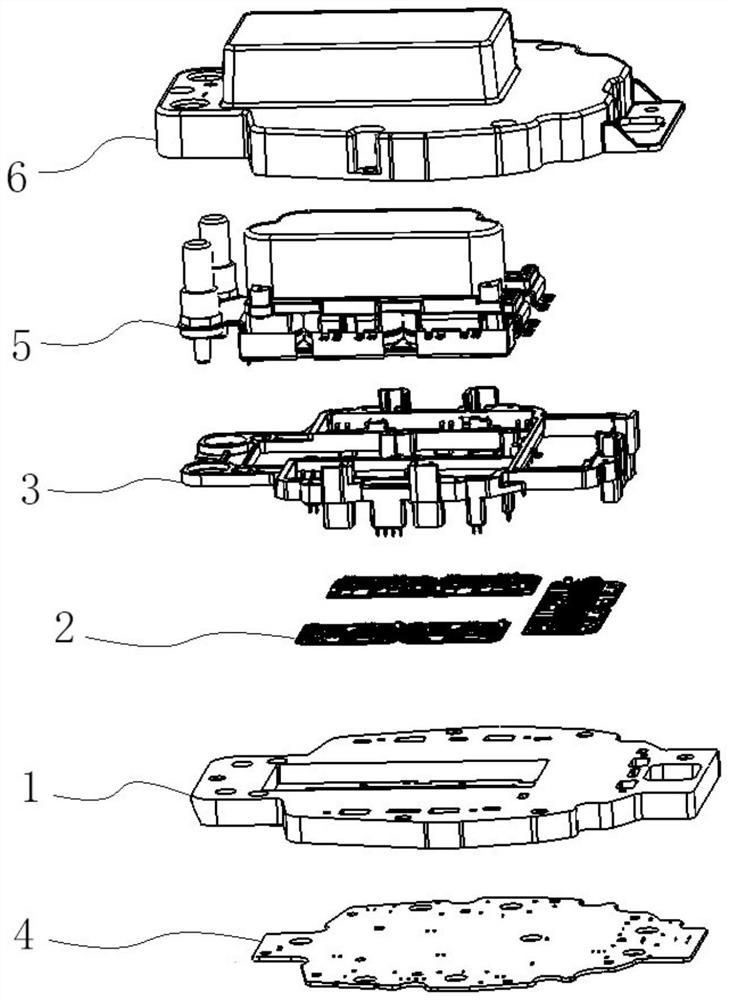

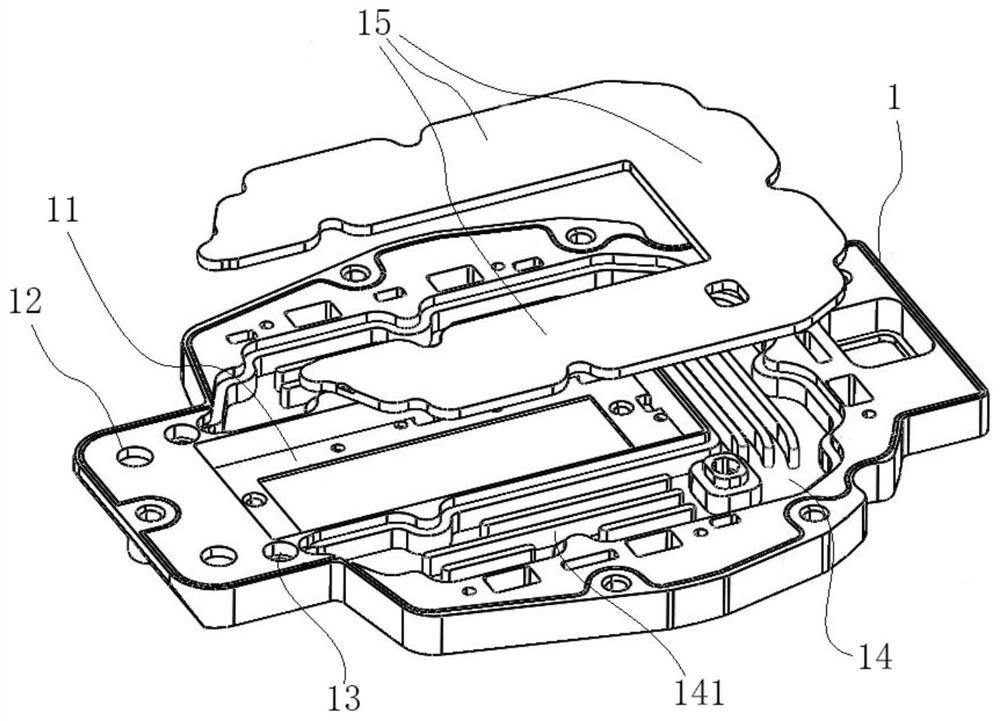

Embodiment 1

[0049] In this embodiment, the welding area 15 of the power module is arranged in three pieces, and the capacitor module installation groove 11 is the center of the square arrangement, which improves the compactness of the present invention. The spoiler 141 is a protrusion arranged on the inner wall of the channel cavity. The protrusion is a columnar spoiler, which has a simple structure and is easy to produce. The round hole is provided with an internal thread, and the internal thread goes straight to the upper end surface of the round hole, which is convenient for use with the faucet. The insulating material is insulating plastic. The through hole is provided with an output screw counterbore on the bearing surface of the capacitor module. The side of the positioning column 5821 is provided with reinforcing ribs to increase the stability of the bracket. The metal shell is made of aluminum alloy. The connecting hole 541 is fixedly connected to the output screw 542 by weldi...

Embodiment 2

[0051] In this embodiment, the spoiler 141 is a protrusion provided on the inner wall of the channel cavity. The protrusion is a columnar spoiler, and the spoiler is arranged along the direction of the flow channel, which can effectively spoil the cooling liquid. The two runner ports 13 are arranged on one side of the bearing surface. The installation hole is provided with an installation counterbore on the assembly surface of the heat dissipation plate, which is beneficial to the integrity of assembly. The capacitor installation surface is evenly provided with more than one capacitor installation position for installing electrolytic capacitors 57 . The capacitor mounting surface is provided with a capacitor support 58 tangentially, and the capacitor support 58 is provided with a capacitor perforation 581 through which the electrolytic capacitor 57 passes. The connecting hole 541 is fixedly connected to the output screw 542 through screw locking. The flatness of the welding...

Embodiment 3

[0053] In this embodiment, the spoiler 141 is a corrugated spoiler arranged on the inner wall of the flow channel cavity, and the spoiler is arranged along the direction of the flow channel, which can effectively spoil the cooling liquid; the circular hole There is a horseshoe-shaped boss under the internal thread, and the horseshoe-shaped opening faces the flow channel. After the water nozzle is screwed down, the lower end surface of the water nozzle contacts the horseshoe-shaped boss, and the cooling medium in the water nozzle enters the flow channel cavity 14 along the horseshoe-shaped direction. The two runner ports 13 are arranged on one side of the assembly surface. The bracket 3 is provided with reinforcing ribs to increase stability. The assembly surface of the heat dissipation plate is provided with a glue groove 36 along the periphery of the power module installation position. The height of the capacitor support 58 is greater than the depth formed by bending the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com