Magnetic engine

An engine and magnet technology, applied in the field of magnetic engines, can solve the problems of emissions, carbon emissions, environmental disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

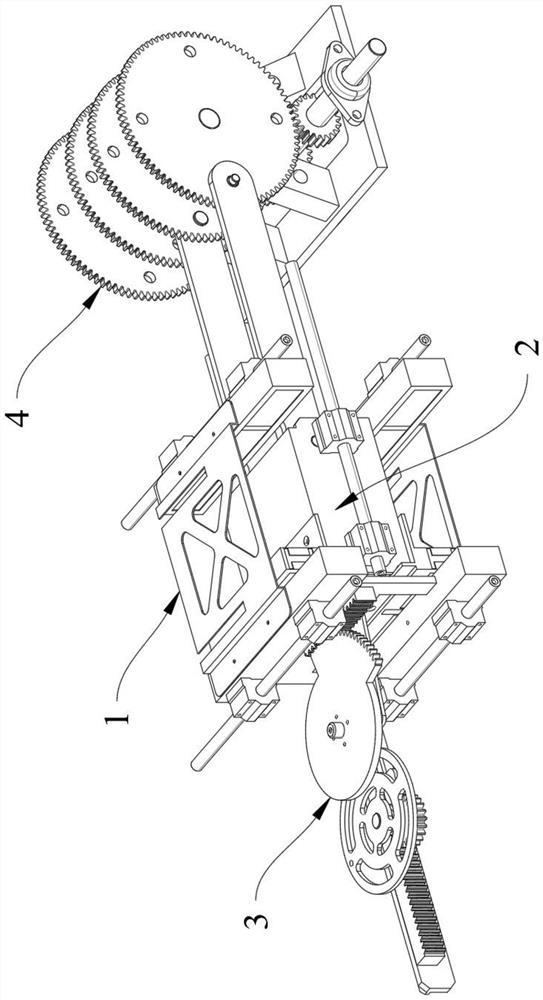

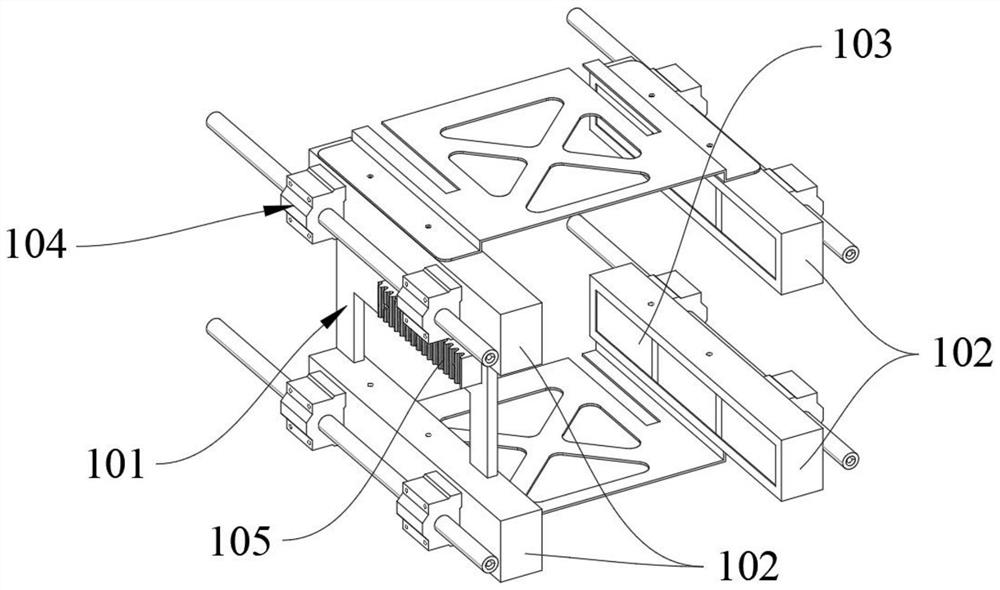

[0039] Please refer to Figure 1 to Figure 11 As shown, this embodiment provides a magnetic engine, including a magnetic power unit; the magnetic power unit includes a magnetic frame 1, a magnetic slider 2 and a magnetic pole switching mechanism 3; the magnetic frame 1 is mounted with a first moving part 104, for providing the magnetic frame 1 with a degree of freedom of reciprocating movement in the front-rear direction, or for providing the magnetic frame 1 with a degree of freedom of reciprocating movement in the circumferential direction of a circle, wherein the axial direction of the circle is the left-right direction; the A second moving part 204 is installed on the magnetic slider 2 to provide the magnetic slider 2 with a degree of freedom of reciprocating movement along the left and right directions; the magnetic frame 1 is respectively provided with a left side and a right side The first magnetic part 102; the first magnetic part 102 includes at least two first magnet...

Embodiment 2

[0049] Please refer to Figure 12As shown, the difference between this embodiment and Embodiment 1 is that the magnetic pole switching mechanism 3 is a second rack and pinion transmission mechanism; the second rack and pinion transmission mechanism includes a The first rack 3b1, the fan-shaped tooth fork 3b2, the rotating wheel 3b4, the gear 3b7 coaxially connected with the rotating wheel 3b4, the second rack 3b8 meshing with the gear 3b7 and installed on the second power transmission part 205; The tooth fork 3b2 is provided with a tooth portion 3b3 that cooperates with the first rack 3b1; the rotating wheel 3b4 is provided with a dial 3b5 near the outer peripheral side, and the sector-shaped tine 3b2 is also provided with a guide that cooperates with the dial 3b5. Slot 3b6; the second power transmission part 205 is used to drive the rotating wheel 3b4 to rotate through the second rack 3b8 to drive the gear 3b7, and then drive the shifting column 3b5 to move, and the cooperati...

Embodiment 3

[0051] Please refer to Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that the magnetic pole switching mechanism 3 is a hydraulic transmission mechanism; the hydraulic transmission mechanism includes a first hydraulic cylinder 3c1, a second hydraulic cylinder 3c2, and a third hydraulic cylinder 3c3; The first hydraulic cylinder 3c1, the second hydraulic cylinder 3c2, and the third hydraulic cylinder 3c3 all include a piston rod, a first oil chamber for controlling the retraction of the piston rod, and a second oil chamber for controlling the extension of the piston rod; The piston rod of a hydraulic cylinder 3c1 is connected to the left end of the first power transmission part 105; the piston rod of the second hydraulic cylinder 3c2 and the piston rod of the third hydraulic cylinder 3c3 are respectively connected to the front end and the rear end of the second power transmission part 205 ; The first oil chamber of the first hydraulic cylinder 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com