High-power semiconductor device with heat dissipation function

A semiconductor, high-power technology, used in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of insulation pressure plate breakage and reduction of compression support structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

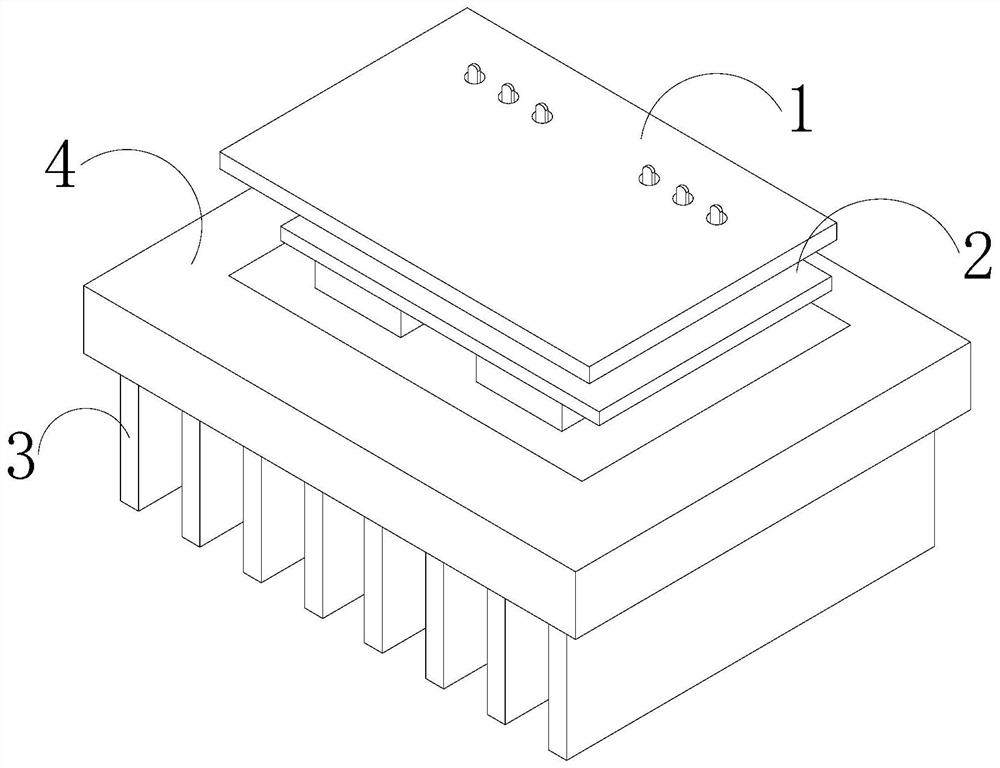

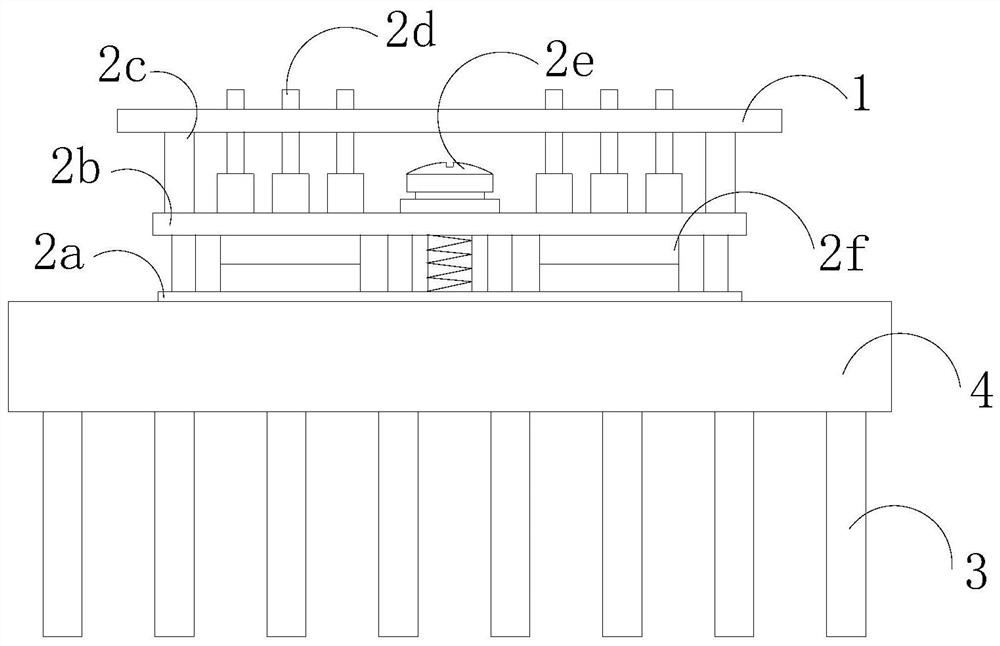

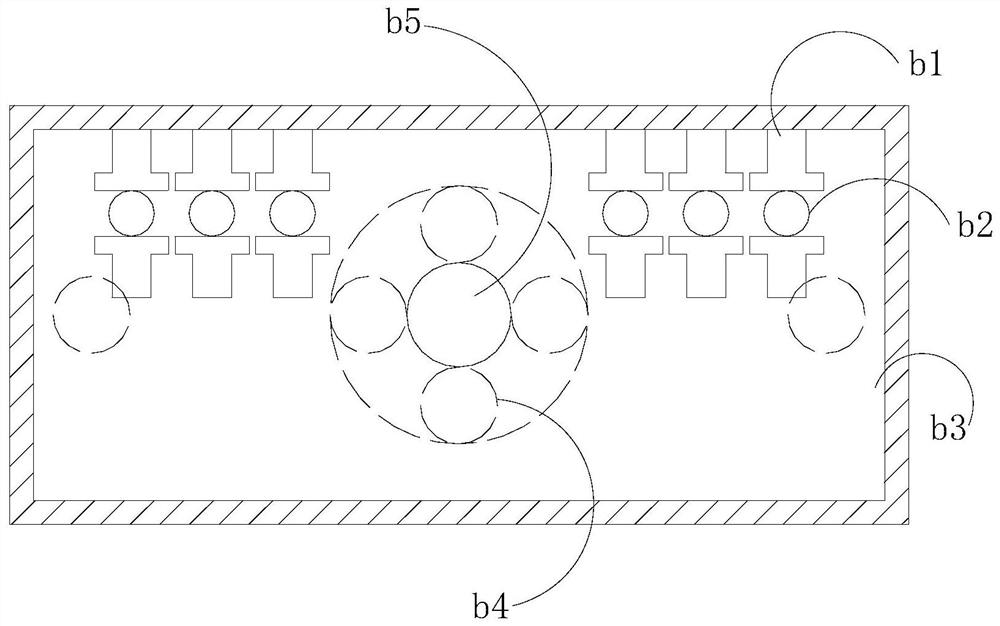

[0027] see Figure 1-Figure 5 , a high-power semiconductor device with heat dissipation, its structure includes a circuit board 1, a regulator 2, a heat sink 3, a heat sink 4, the bottom of the heat sink 4 is provided with a heat sink 3, and the heat sink 3 is connected to the heat sink The body 4 is movably connected, and the regulator 2 is provided with a circuit board 1, and the circuit board 1 and the regulator 2 are in clearance fit;

[0028] The regulator 2 is provided with a thermal pad 2a, an operator 2b, a mounting seat 2c, a pin 2d, a fastener 2e, and a semiconductor 2f, and the semiconductor 2f is provided with a pin 2d, and the pin 2d is connected to the semiconductor 2f. The central position of the operator 2b is provided with a fastener 2e, the fastener 2e is in clearance fit with the operator 2b, the semiconductor 2f is installed on the heat conduction pad 2a, and the heat conduction pad 2a and the semiconductor 2f The manipulator 2b is provided with a mounting...

Embodiment 2

[0036] see Figure 1-Figure 6 , a high-power semiconductor device with heat dissipation, its structure includes a circuit board 1, a regulator 2, a heat sink 3, a heat sink 4, the bottom of the heat sink 4 is provided with a heat sink 3, and the heat sink 3 is connected to the heat sink The body 4 is movably connected, and the regulator 2 is provided with a circuit board 1, and the circuit board 1 and the regulator 2 are in clearance fit;

[0037] The regulator 2 is provided with a thermal pad 2a, an operator 2b, a mounting seat 2c, a pin 2d, a fastener 2e, and a semiconductor 2f, and the semiconductor 2f is provided with a pin 2d, and the pin 2d is connected to the semiconductor 2f. The central position of the operator 2b is provided with a fastener 2e, the fastener 2e is in clearance fit with the operator 2b, the semiconductor 2f is installed on the heat conduction pad 2a, and the heat conduction pad 2a and the semiconductor 2f The manipulator 2b is provided with a mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com