HMDS leakage-proof protection device for spin coating developer

A protection device and developing machine technology, applied in photography, opto-mechanical equipment, photo-engraving process of pattern surface, etc., can solve the problem of easy leakage of HMDS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

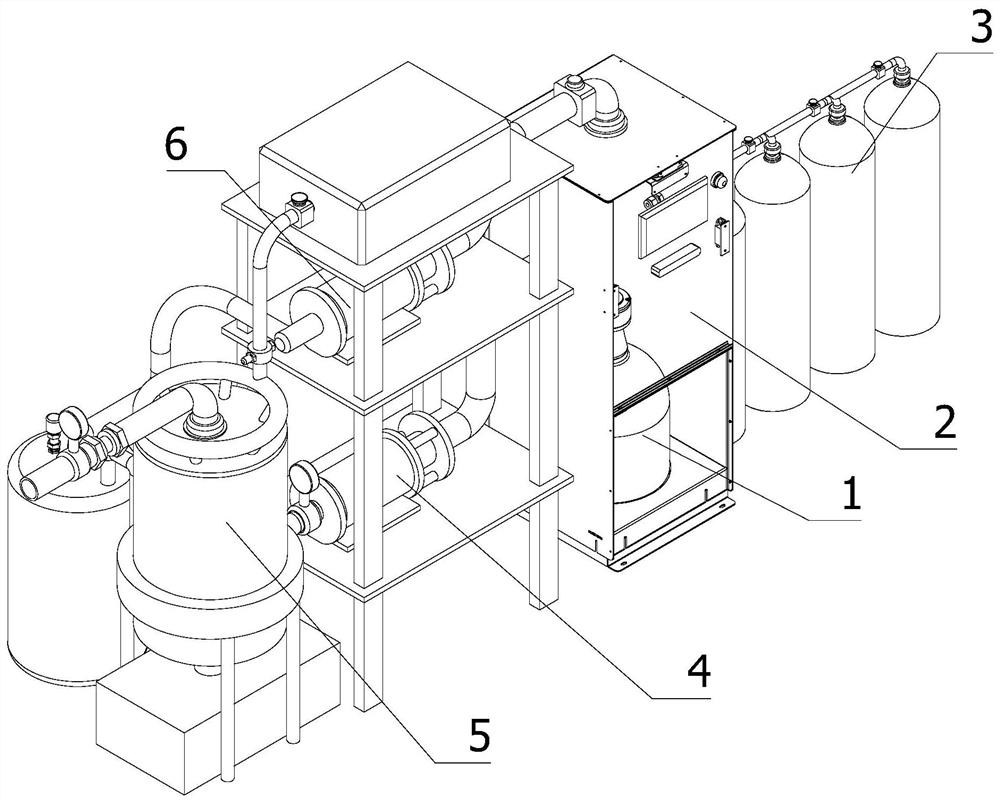

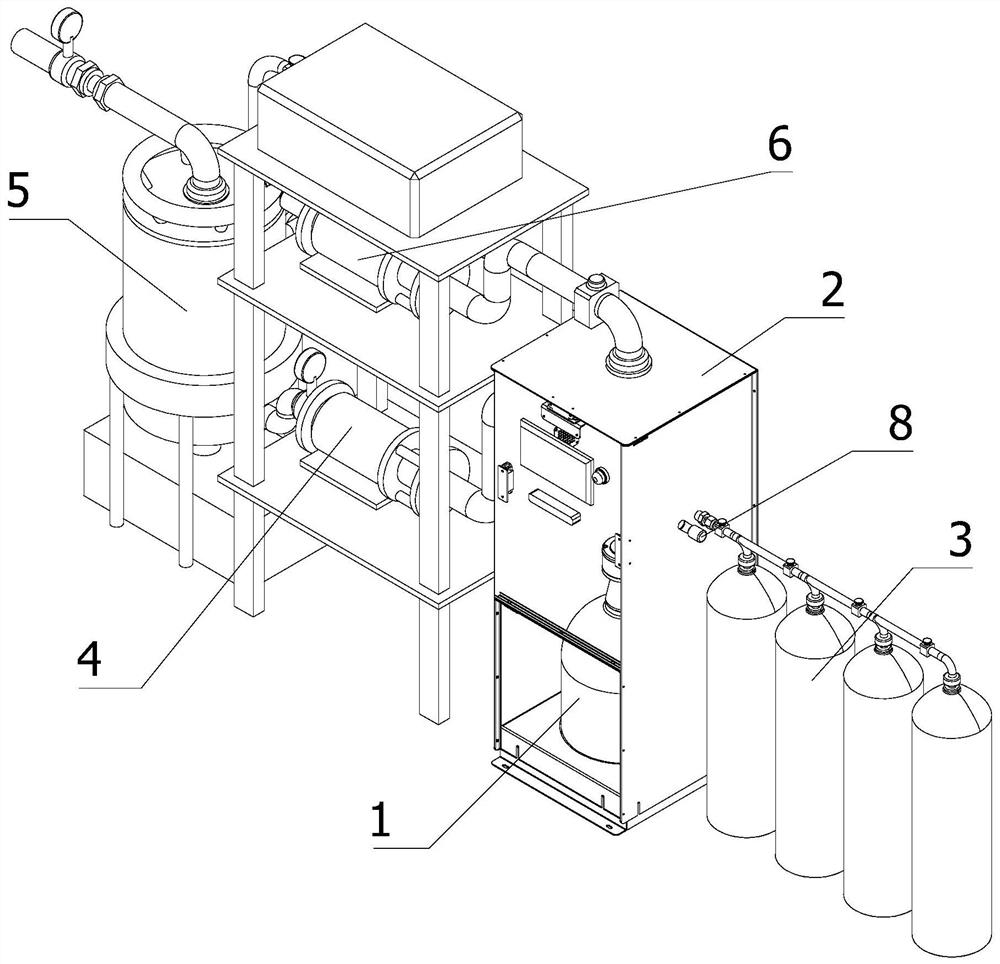

[0050] like Figure 1-4 As shown, a kind of HMDS anti-leakage protection device for the glue-leveling developing machine of the present embodiment comprises:

[0051] HMDS tank 1, used to provide HMDS gas;

[0052] A sealed protective cover 2, the HMDS tank 1 is installed inside the sealed protective cover 2, and the inside of the sealed protective cover 2 is in a sealed state;

[0053] The nitrogen feeding mechanism 3 is arranged on the side of the sealing protective cover 2, and the output end of the nitrogen feeding mechanism 3 extends to the inside of the sealing protective cover 2 for providing nitrogen;

[0054] Also includes:

[0055] The frame is arranged on the side of the sealing protective cover 2;

[0056] Exhaust mechanism 4, is installed on the frame, and the exhaust end of exhaust mechanism 4 is arranged on the inside of sealing protective cover 2, and the exhaust end of exhaust mechanism 4 is arranged on the outside of sealing protective cover 2, is used for...

Embodiment 2

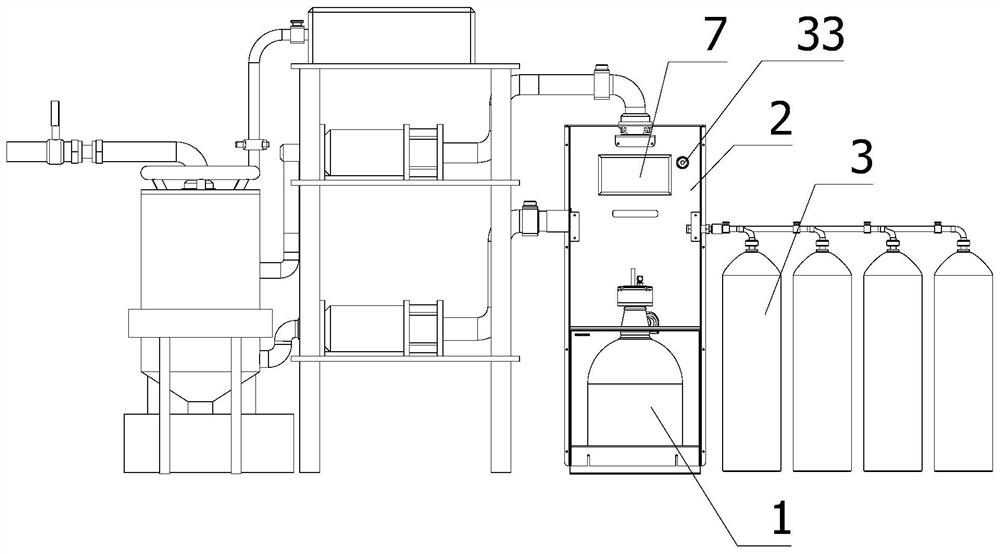

[0079] Compared with Embodiment 1, in this embodiment, in order to solve the technical problem of how to automatically recycle and collect HMDS, such as Figure 9 Shown:

[0080] Automatic recovery mechanism 6 comprises a second air pump 22, a second air pipe 23, a second air guide pipe 24 and a high-pressure collection tank 25, the second air pump 22 is installed on the frame, and one end of the second air pipe 23 is connected to the sealing protective cover The inner top of 2 is sealed and communicated, the other end of the second air extraction pipe 23 communicates with the air extraction end of the second air extraction pump 22, the high-pressure collection tank 25 is arranged on the side of the frame, and one end of the second air guide pipe 24 is connected to the second air extraction pump. The exhaust end of 22 communicates, and the other end of the second air guide pipe 24 is connected with the high-pressure collection tank 25 internally.

[0081]Specifically, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com