Heat exchange performance testing system for heat storage elements of rotary air pre-heater

A heat transfer performance and testing system technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problem of not extracting the characteristics of reverse flow of rotary air preheater and regenerative heat transfer, and the evaluation conclusion is not accurate enough Objectivity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

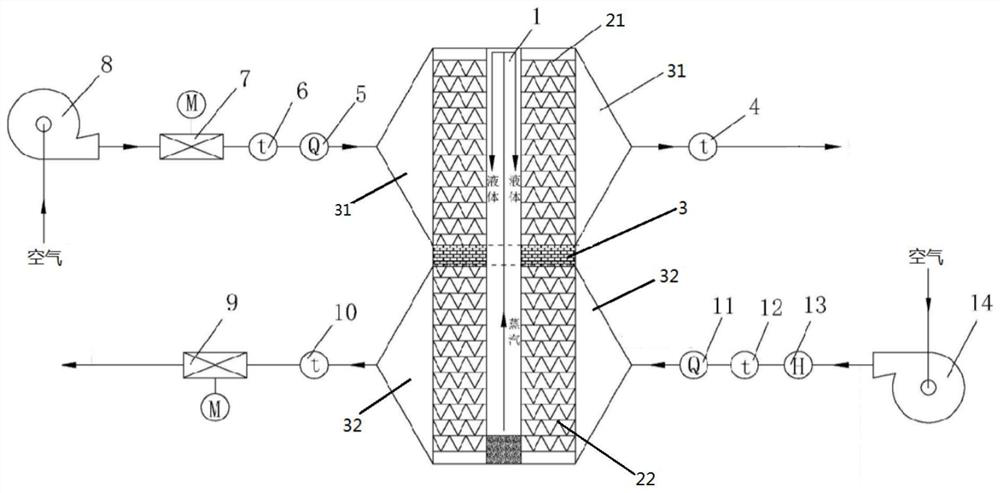

[0034] The present invention is a heat transfer performance testing system for heat storage elements of a rotary air preheater, comprising

[0035] Gravity heat pipe 1, heat storage element 21 in the heating section, heat storage element 22 in the cooling section, and annular heat insulation layer 3;

[0036] The heat storage element 21 of the heating section, the annular heat insulation layer 3 and the heat storage element 22 of the cooling section are sequentially set on the side wall of the gravity heat pipe 1 from top to bottom, and the annular heat insulation layer 3 connects the heat storage element 21 of the heating section and the cooling section The thermal storage element 22 is thermally insulated and connected;

[0037] The outside of the heat storage element 21 in the heating sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com