Paint remover for ABS plastic base material, and preparation method and use method thereof

A technology of ABS plastic and paint remover, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of high sodium hydroxide content, easy damage to the substrate, affecting the direct reuse of the substrate, etc. Inexpensive and easy to obtain, the effect is conducive to promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] As an aspect of the present invention, provide a kind of preparation method of paint stripper for ABS plastic base material, described paint stripper is used for removing vacuum electroplating aluminum and coating on ABS plastic base material simultaneously, described method comprises as follows step:

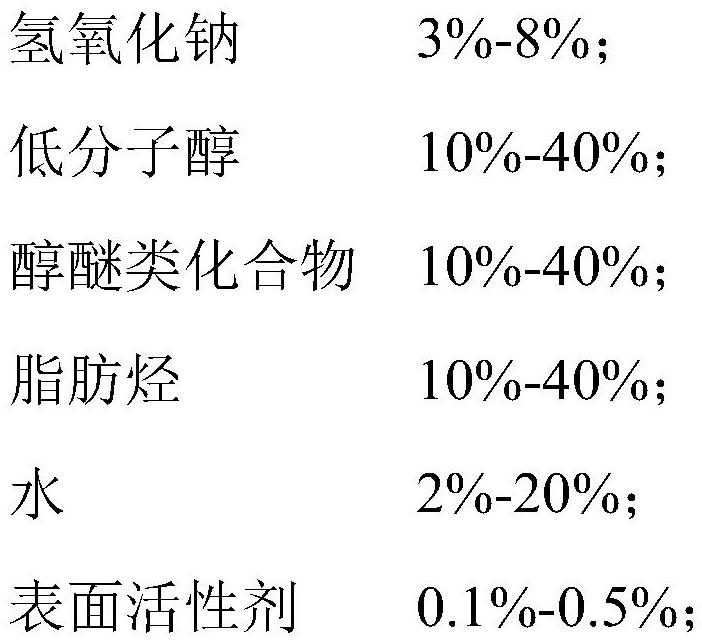

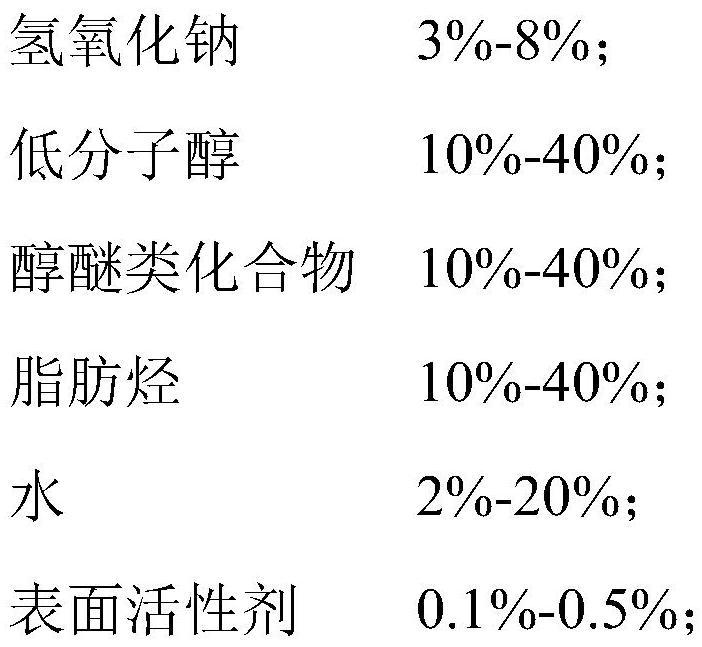

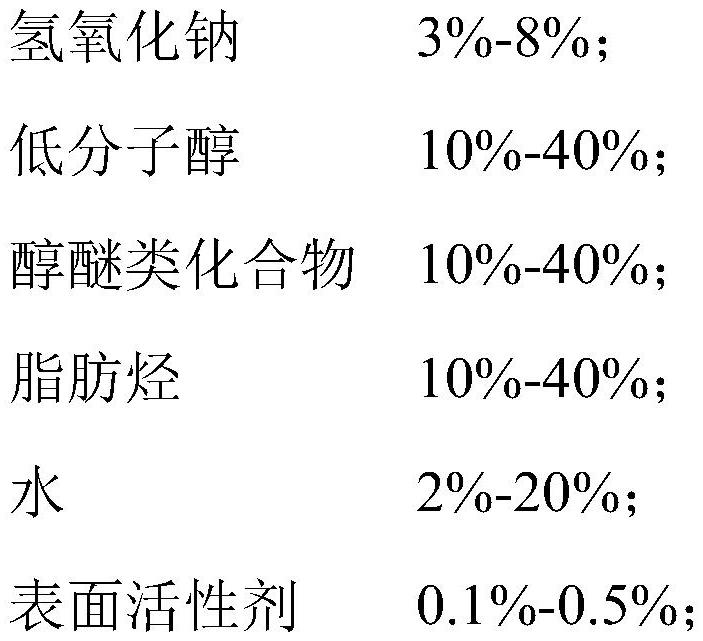

[0029] Choose the raw material of following mass percentage:

[0030]

[0031] Wherein, in a specific example, the ratio of each raw material is as follows by weight:

[0033] Low molecular alcohol 29.5%;

[0034] Alcohol ether compounds 30%;

[0035] Aliphatic hydrocarbons 25%;

[0036] water 10%;

[0037] Surfactant 0.5%.

[0038] First prepare the aforementioned sodium hydroxide and water into a sodium hydroxide solution, then add low-molecular alcohol and one-half amount of alcohol ether compounds, after the phase state is stable, add aliphatic hydrocarbons and another half alcohol ether compounds, and finally A surfactant is a...

Embodiment 2

[0047] As another aspect of the present invention, a paint remover for ABS plastic substrates is also provided, which is prepared by the preparation method described in the first embodiment above.

Embodiment 3

[0049] As another aspect of the present invention, also provide a kind of use method for the paint stripper of ABS plastic substrate, it comprises steps:

[0050] Choose the paint stripper that is used for the ABS plastic base material in the aforementioned embodiment two;

[0051] Soak all the workpieces to be depainted in the paint remover, or use a brush or cotton yarn to smear the paint remover on the parts of the workpiece to be depainted;

[0052] After waiting for 5-120 minutes, rinse the residual paint flakes on the surface of the workpiece to be depainted with water.

[0053] It can be understood that the embodiment of the present invention provides a paint stripper for ABS plastic substrates, the paint stripping principle is: aliphatic hydrocarbon dissolves or swells the resin, destroys topcoat, primer coating on metal plating, substrate Excellent surface adhesion, but no corrosion or damage to the ABS substrate; sodium hydroxide reacts with the vacuum electroplatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap