Preparation method of waste tire thermal cracking carbon black electrode material for supercapacitor

A technology of thermal cracking carbon black and supercapacitors, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, fibrous fillers, etc., and can solve problems such as failure to meet standards and low activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

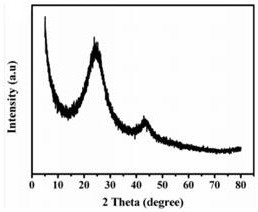

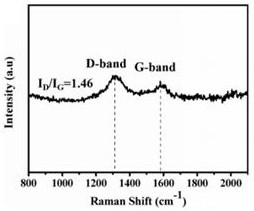

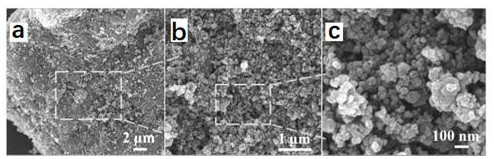

Image

Examples

Embodiment 1

[0031] 1) Put 10 g tire pyrolysis carbon black in a quartz boat, spread it evenly, then place it in the heating tube of a common tube furnace, and raise the temperature at a rate of 5 ℃ / min under the flow rate of 200 mL / min carbon dioxide gas The rate was increased from room temperature to 1000 °C for 2 h of heat treatment and activation. After the reaction was completed, it was cooled to room temperature, and the sample was taken out to obtain the first activated product.

[0032] 2) Weigh 5 g of the first activated product obtained in step 1), then add KOH for mixing according to the mass ratio of 1:4, then add 100 mL of CTAB solution with a concentration of 0.01 M in a beaker, and put it in a heating magnetic stirrer Heat to 50°C and stir for 12 hours to fully and evenly mix KOH and thermal cracking carbon black. After the stirring is completed, transfer to a blast drying oven for 8 hours at a temperature of 80°C until no obvious solution exists. Raise the temperature from ...

Embodiment 2

[0035] 1) Put 10 g tire pyrolysis carbon black in a quartz boat, spread it evenly, then place it in the heating tube of a common tube furnace, and raise the temperature at a rate of 5 ℃ / min under the flow rate of 300 mL / min carbon dioxide gas The rate was increased from room temperature to 1000 °C for 2 h of heat treatment and activation. After the reaction was completed, it was cooled to room temperature, and the sample was taken out to obtain the first activated product.

[0036]2) Weigh 5 g of the first activated product obtained in step 1), then add KOH for mixing according to the mass ratio of 1:4, then add 100 mL of CTAB solution with a concentration of 0.01 M in a beaker, and put it in a heating magnetic stirrer Heat to 50°C and stir for 12 hours to fully and evenly mix KOH and thermal cracking carbon black. After the stirring is completed, transfer to a blast drying oven for 8 hours at a temperature of 80°C until no obvious solution exists. Raise the temperature from r...

Embodiment 3

[0039] 1) Put 10 g tire pyrolysis carbon black in a quartz boat, spread it evenly, then place it in the heating tube of a common tube furnace, and raise the temperature at a rate of 5 ℃ / min under the flow rate of 300 mL / min carbon dioxide gas The rate was increased from room temperature to 1000 °C for 2 h of heat treatment and activation. After the reaction was completed, it was cooled to room temperature, and the sample was taken out to obtain the first activated product.

[0040] 2) Weigh 5 g of the first activated product obtained in step 1), then add KOH for mixing according to the mass ratio of 1:4, then add 100 mL of CTAB solution with a concentration of 0.01 M in a beaker, and put it in a heating magnetic stirrer Heat to 50°C and stir for 12 hours to fully and evenly mix KOH and thermal cracking carbon black. After the stirring is completed, transfer to a blast drying oven for 8 hours at a temperature of 80°C until no obvious solution exists. Raise the temperature from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com