Synthesis of temperature and pH dual-stimulation-responsive nano hydrogel and water-based drilling fluid

A dual-stimuli-responsive, nano-hydrogel technology, applied in the field of water-based drilling fluids, can solve problems such as wellbore instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

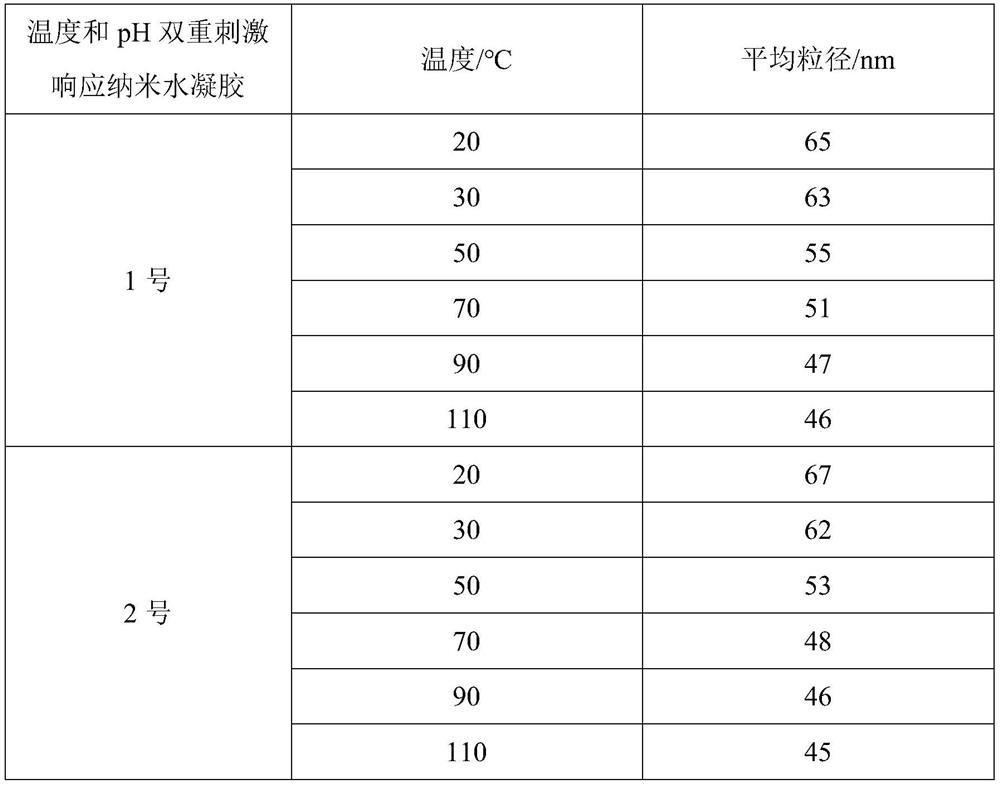

[0029] Dry the nano-silica in a vacuum drying oven at 75°C for 14 hours, accurately weigh 2 g of the dried nano-silica, add it to 40 mL of ethanol / water dispersion (volume ratio is 4.5:1), and disperse by ultrasonic for 45 minutes , then add 2g KH570 dropwise while stirring, react at 75°C for 11h, wash with ethanol, repeat 4 times, and finally place in a vacuum oven at 55°C for 7h to obtain modified nano-silica.

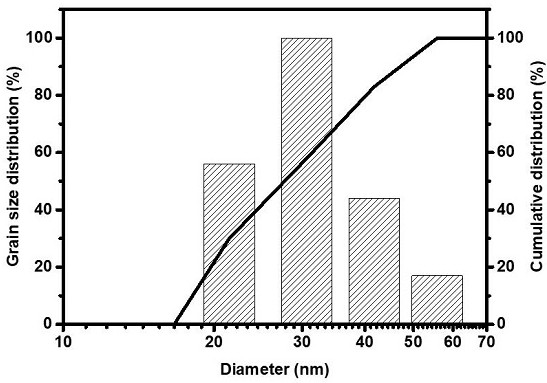

[0030] Weigh 0.17g of modified nano-silica and put it in a beaker, add 50ml of distilled water and ultrasonically disperse it for 10min, then transfer it to the reactor, weigh 1.54g of N-isopropylacrylamide, 0.15g of acrylic acid and N,N - Dissolve 0.03g of methylene acrylamide in deionized water and transfer them into the reactor, and stir them magnetically for 2 hours; after raising the temperature of the reactor to 60°C, add 0.06g of potassium persulfate to the reaction system and react for 6 hours; After natural cooling, wash with distilled water until the pH is ...

Embodiment 2

[0032] Dry nano-silica in a vacuum oven at 80°C for 13 hours, accurately weigh 2.5 g of dried nano-silica, add it to 50 mL of ethanol / water dispersion (volume ratio 5:1), and ultrasonically disperse 50min, then add 2.5g KH570 dropwise while stirring, react at 80°C for 12h, wash with ethanol, repeat 5 times, and finally dry in a vacuum oven at 60°C for 8h to obtain modified nano-silica.

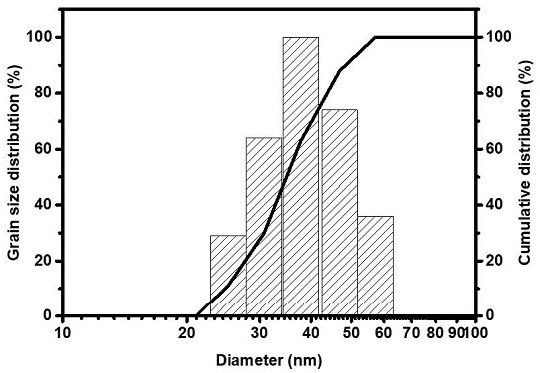

[0033] Weigh 0.25g of modified nano-silica and place it in a beaker, add 50ml of distilled water and ultrasonically disperse it for 10min, then transfer it to the reactor, 1.27g of N-tert-butylacrylamide, 0.17g of allylamine and N,N- Dissolve 0.38g of octamethylenebisacrylamide in deionized water and transfer to the reactor, then pass through nitrogen for 25 minutes to remove oxygen; after the reactor is heated to 60°C, add 0.08g of ammonium persulfate to the reaction system React for 7 hours; after the reaction system is naturally cooled, wash with distilled water until the pH is 7, soak in d...

Embodiment 3

[0035] The configuration of water-based drilling fluid: based on 100 parts by weight of fresh water, the present embodiment illustrates the formula of water-based drilling fluid by the following method. The specific formula of water-based drilling fluid is as follows: 100 parts by weight of water+4 parts by weight of bentonite+0.2 parts by weight Parts of NaOH+0.02 parts by weight of KPAM+0.4 parts by weight of PAC-LV+5 parts by weight of RSTF+5 parts by weight of SMP-1+5 parts by weight of FRH+1 part by weight of PPL+4 parts by weight of FK-10+0.4 parts by weight of SP-80 +1.2 parts by weight desulfurizer+0.4 parts by weight CaO+10 parts by weight barite.

[0036] 1) Prehydration of bentonite slurry

[0037] At room temperature, add 4 parts by weight of bentonite evenly into 100 parts by weight of tap water while stirring, then add 0.2 parts by weight of soda ash, stir for 30 minutes at a speed of 2000 r / min, seal and let stand for 24 hours , to obtain pre-hydrated bentonite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com