Special organic fertilizer for flue-cured tobacco and preparation method thereof

A technology of organic fertilizer and flue-cured tobacco, applied in the direction of organic fertilizer, chemical fertilizer treatment control, bio-organic part treatment, etc., can solve the problems that cannot effectively improve the quality of tobacco planting soil, low nutrient content, single type of organic fertilizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

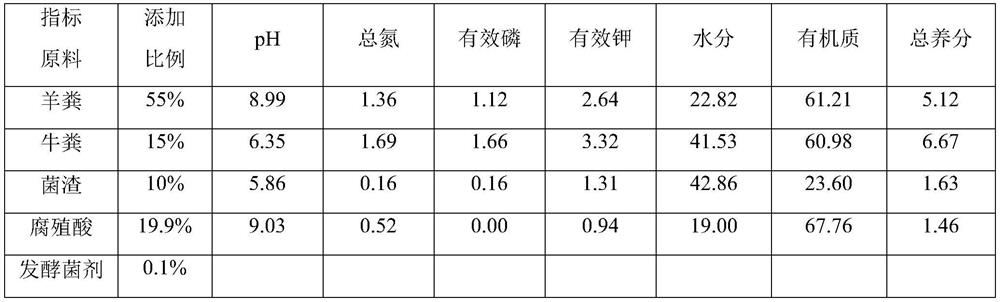

[0043] The special organic fertilizer for flue-cured tobacco described in this example is prepared through a fermentation process, specifically, it is obtained by fermentation using a nano-membrane organic waste stacking technology. In terms of weight ratio, it includes the following raw material components:

[0044]Component 1) 63% to 76% of cattle and sheep manure. The addition ratio of cattle and sheep manure is any ratio within the range of 63% to 76%, and the recommended addition ratio is 70% of the total weight of the material. The cow and sheep manure refers to a mixture of cow manure and sheep manure, uniformly mixed in a weight ratio of 10-12:2.5-4, preferably 11:3. A variety of active enzymes contained in cow and sheep manure can improve the performance of soil water and fertilizer retention, promote the formation of soil aggregate structure, loosen the soil, improve soil physical and chemical properties, and stimulate the growth and development of flue-cured tobacc...

Embodiment 2

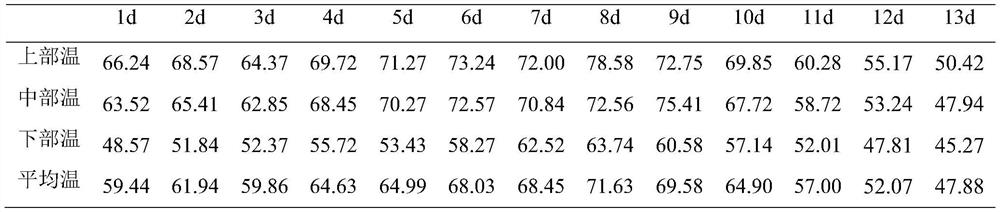

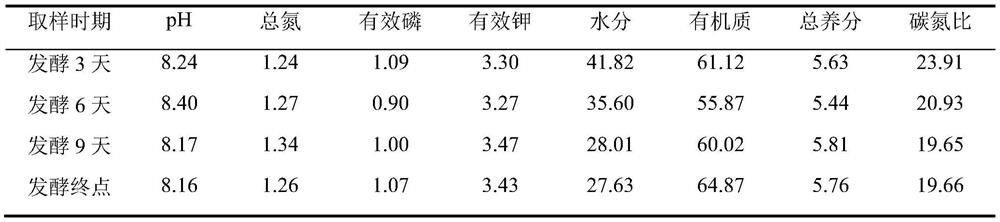

[0050] This example is a preparation example of the special organic fertilizer for flue-cured tobacco described in Example 1.

[0051] Step 1) select fermentation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com