Composite glass fiber winding machine and application method thereof

A technology of glass fiber roll and winding mechanism, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient glass fibers, easily broken wires, entanglement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

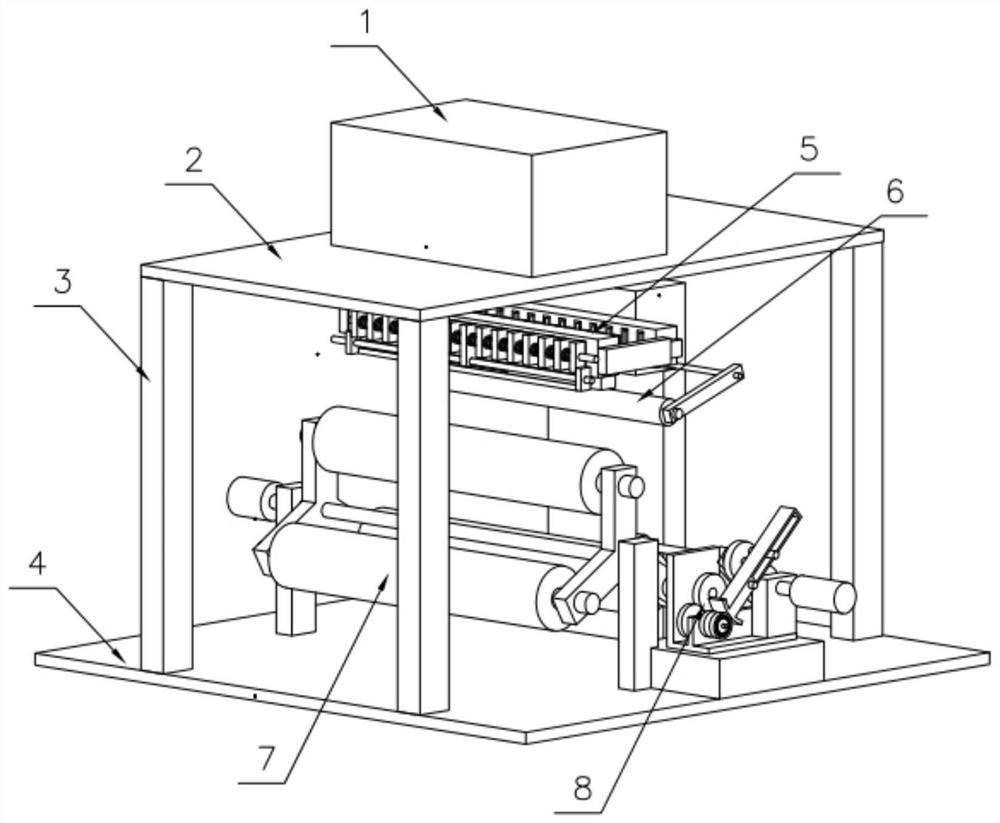

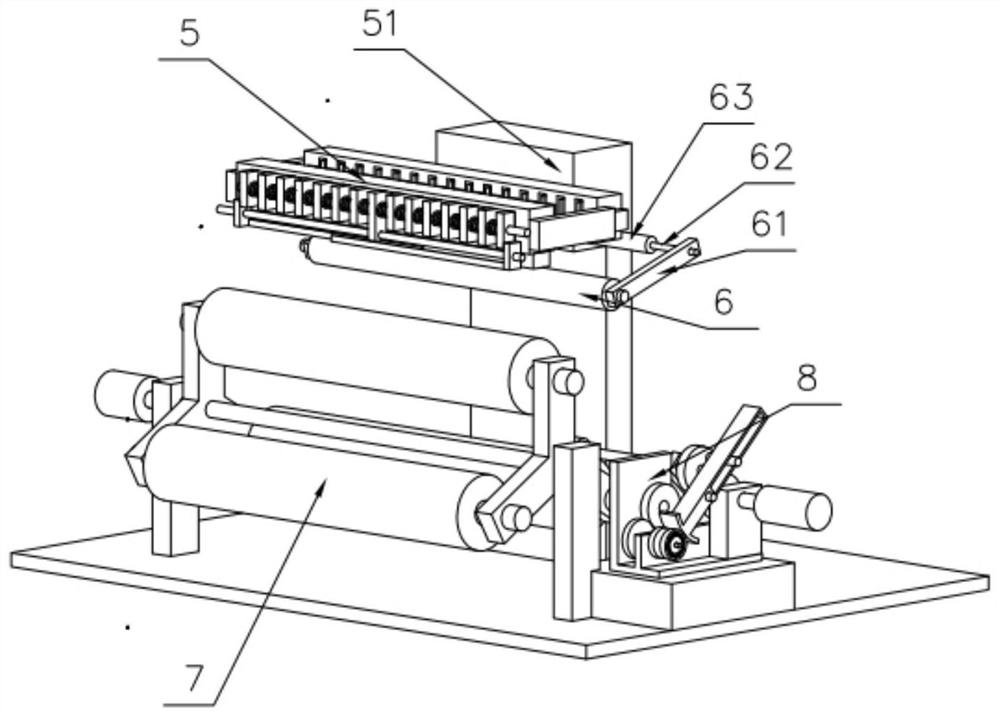

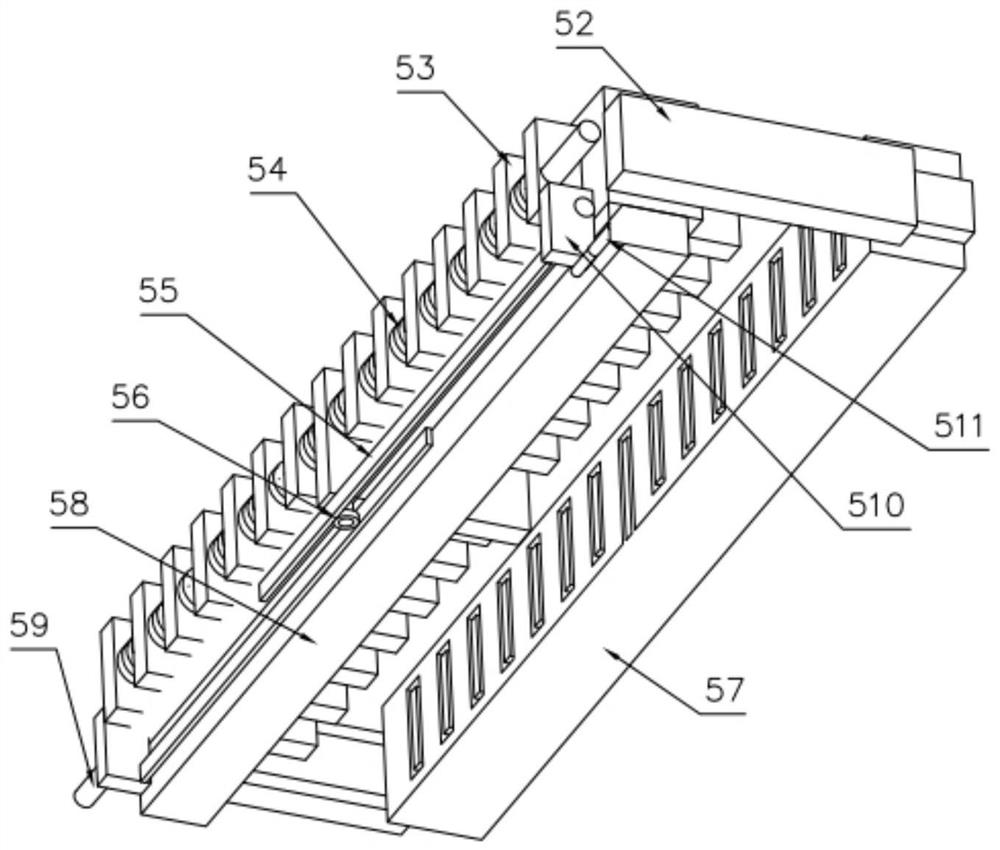

[0031] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-8 , to further specifically describe the technical solution of the present invention.

[0032] A composite glass fiber winding machine, placed in the lower part of the dipping tank 1, including a base 4, a column 3, an extrusion mechanism 5, a conversion mechanism 7, and a winding mechanism 8. The upper part of the base 4 is provided with an upper support plate 2, The upper support plate 2 is connected to the base 4 through several columns 3, the upper part of the upper support plate 2 is provided with a dipping tank 1, and the lower part of the dipping tank 1 is provided with a winding wheel 73, and the winding wheel 73 is movable Connected to the base 4, a winding mechanism 8 is provided on one side of the winding wheel 73;

[0033]The winding mechanism 8 includes a winding motor 81, a rotating rod 85, a ring gear 852, and a one-way wheel 813. A sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com