Assembly tool for perforated pipe silencer

A technology for assembly tooling and mufflers, which is applied to workbenches, manufacturing tools, hand-held tools, etc., can solve problems such as unsatisfactory assembly accuracy, difficult precise positioning, and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

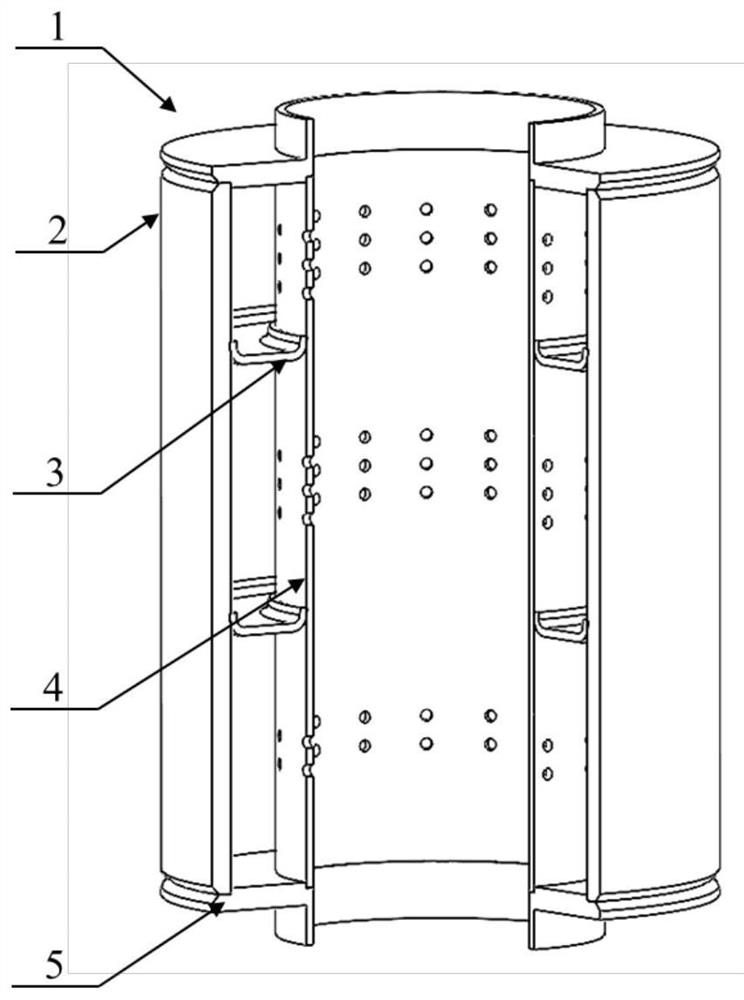

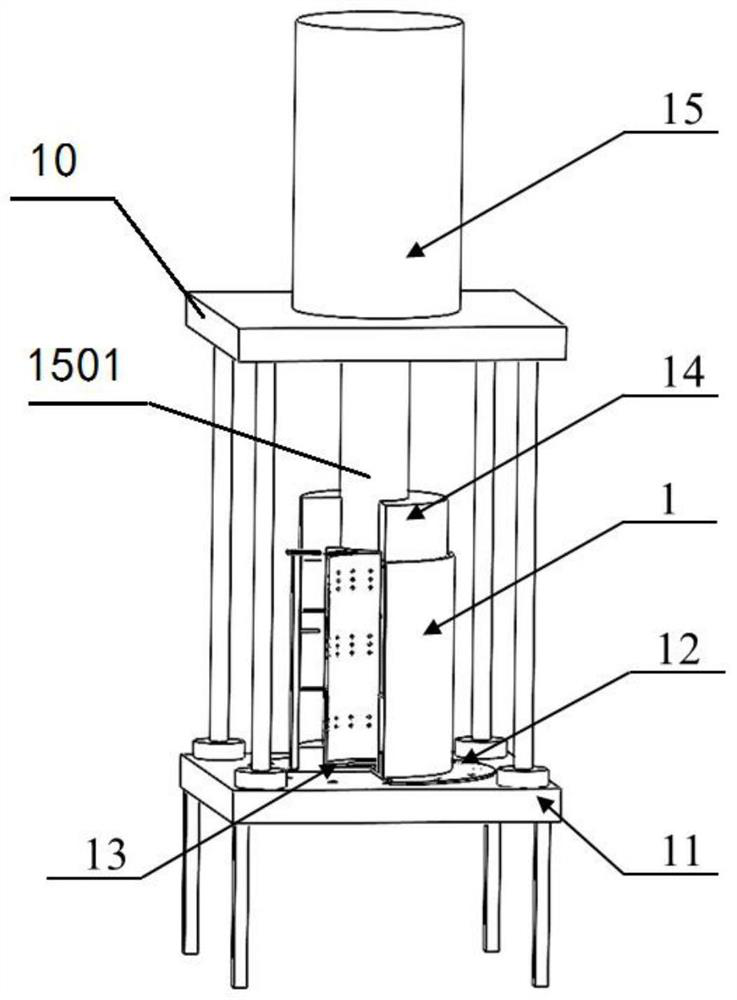

[0043] In a first embodiment, such as figure 2 , The present invention is provided on the table 10, the table 11, the positioning unit 12, the annular spacer 13, the slide positioning means 14 of an apertured tube assembly tooling muffler 1, the perforated tube 1 muffler assembly tooling including and a power drive device 15, the seat 12 is positioned so that the outer perforated tube muffler tube and the inner tube 2 1 of 4 concentric annular spacer 13 for adjusting the perforated tube of the muffler outer tube 1 and inner tube 2 4 relative axial height. The slide positioning means 14 for determining the relative position of the baffle within the muffler 1, 3 within the outer tube 2 in the perforated tube, the powered device 15 is used to overcome inner tube and the outer flap 3 2 and the inner tube 4 through the clearance fit or an interference fit results in resistance to downward movement, to achieve the axial positioning of the shutter 3.

[0044]The muffler perforated tube 1...

Embodiment 2

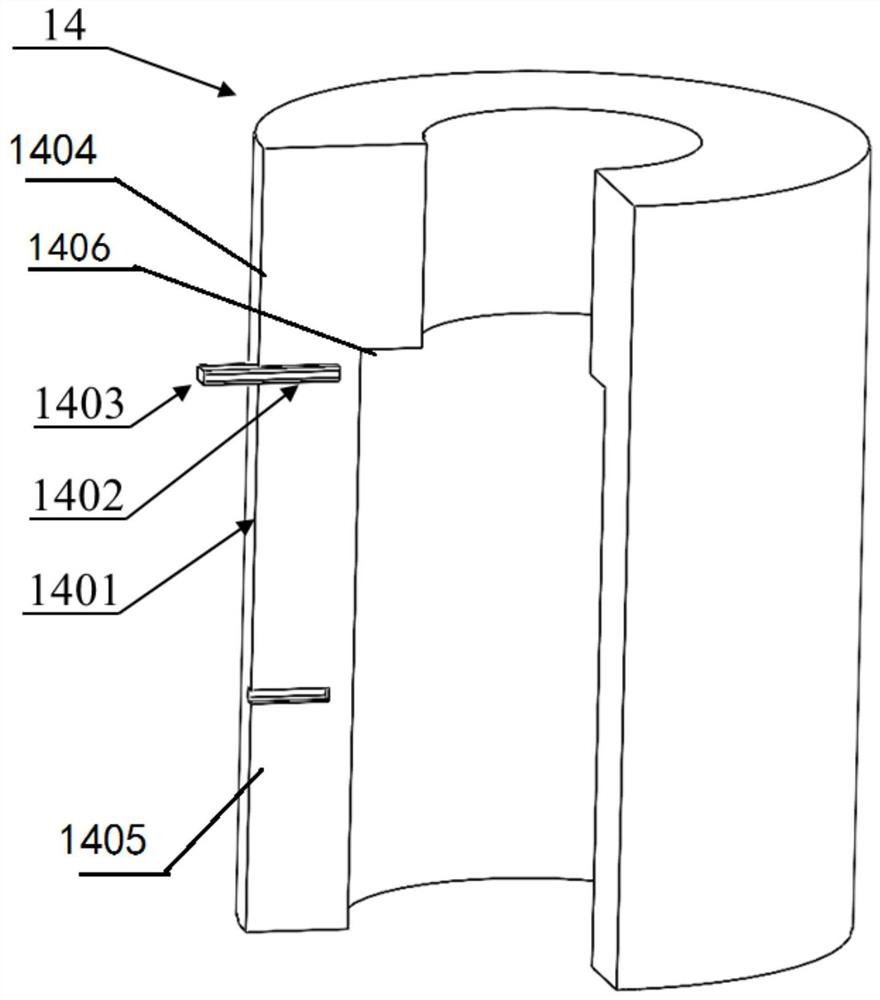

[0056] Please refer to Figure 5-6 ,in, Figure 5 An apertured tube muffler assembly of the present invention a tooling structure diagram, Image 6 for Figure 5 I in an enlarged partial section of FIG.

[0057] In a second embodiment, all structures provided in Example 1, but the embodiment is provided in the form of an annular positioning and configuration of the separator.

[0058] In particular, the annular positioning on the number of the positioning projections 12 a plurality of 1203, all of the annular positioning boss 1203 coaxially disposed, but different radii, concentric annular ring structures are formed. Corresponding adjacent two of the annular positioning boss 1202 is formed an annular groove 1203 between the innermost annular projection 1203 is positioned inside a circular groove 1202 is formed, thus positioning seat number 12 on the annular recess 1202 of a plurality of, with the use of a variety of specifications of the perforated tube positioned muffler 1 and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com