Cooling system and method for high-temperature ammonia spraying denitration air cooling spray gun of coal-fired boiler

A coal-fired boiler and cooling system technology, which is applied to the cooling system field of high-temperature ammonia injection and denitrification air-cooled spray guns of coal-fired boilers, and can solve problems such as affecting efficiency and increasing the surface temperature of the spray gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

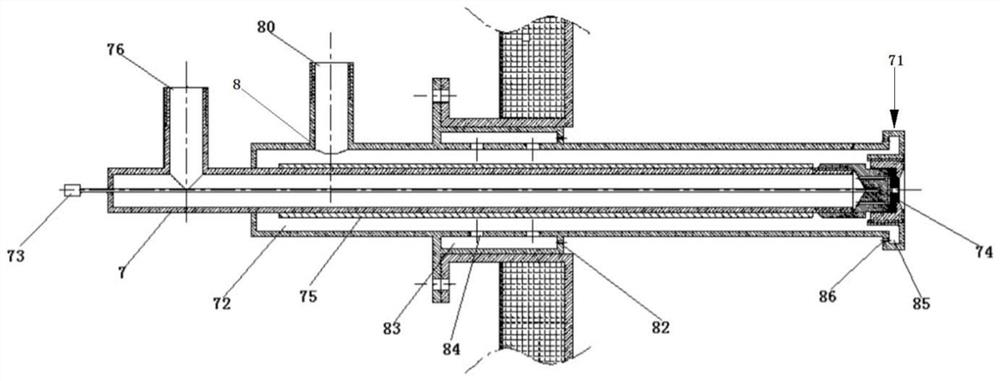

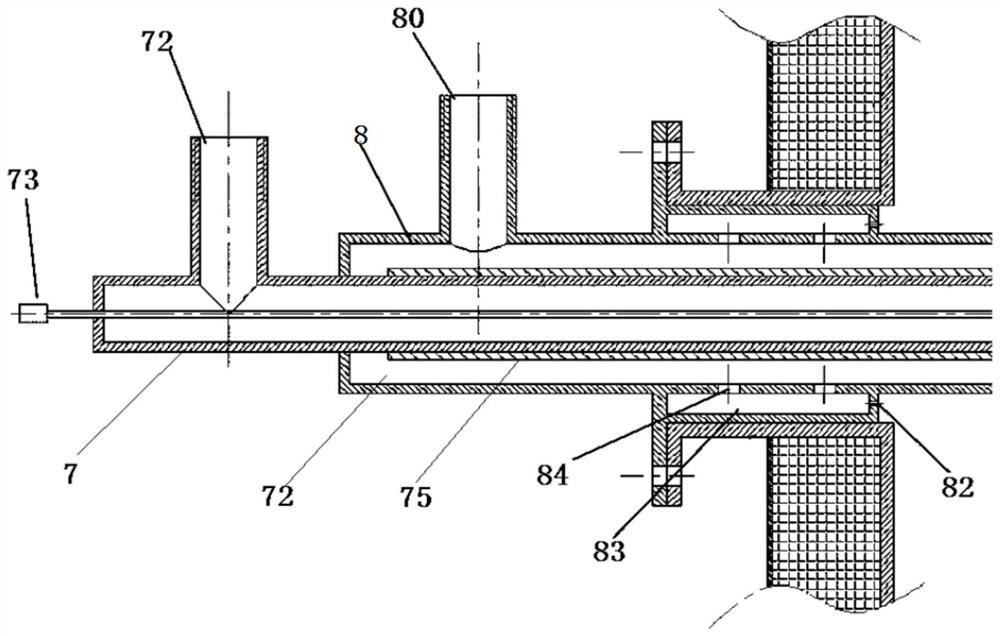

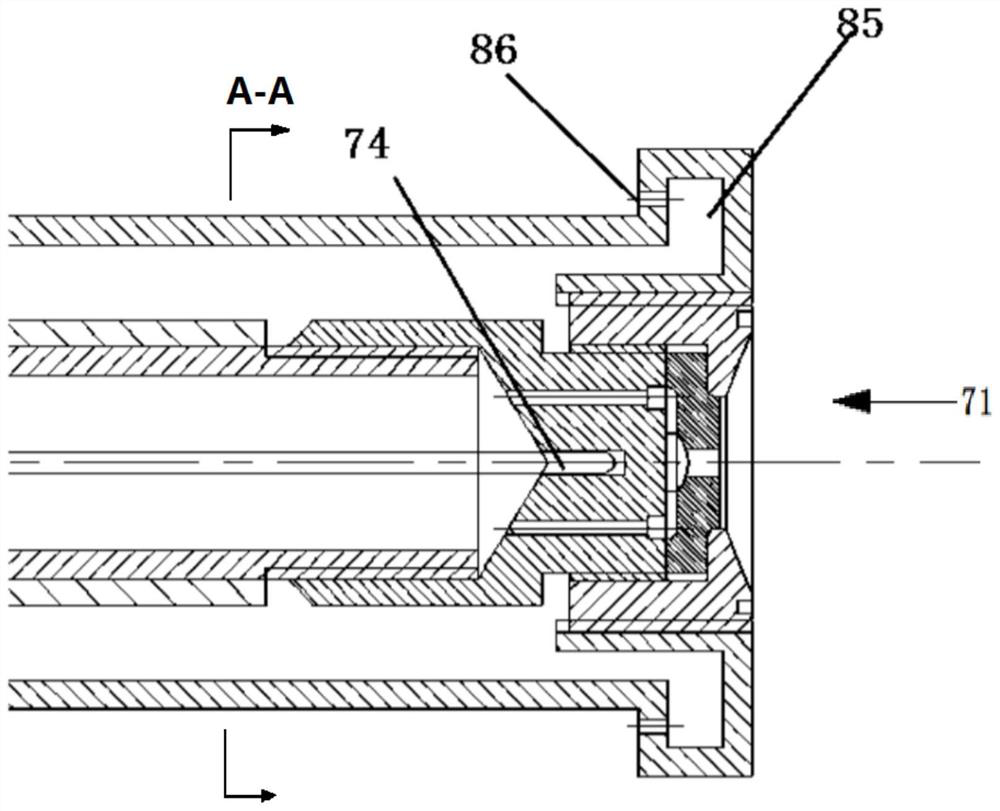

[0030] A specific embodiment of the cooling system of the high-temperature ammonia spraying denitrification air-cooled spray gun of a coal-fired boiler of the present invention, as figure 1 As shown, it includes a spray gun pipe 7 and an air cooling jacket 8; one end of the spray gun pipe 7 is a spray gun head air cooling jacket 71 and is arranged inside the boiler, and the other end is connected to the reducing agent interface 76 and is arranged outside the boiler; the air cooling jacket 8 is set on The outer side of the air-cooling jacket 8 of the spray gun pipe, and forms a cooling air cavity 72 with the outer wall of the spray gun pipe 7. The air-cooling jacket 8 is provided with a cooling air interface air-cooling jacket 80 on the side wall at one end outside the boiler; A plurality of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com