Low-bitterness L-menthol and preparation method thereof

A levomenthol and low-bitterness technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the bitter aftertaste, unstable sweetness of bitter masking agents, and the inability of levomenthol to maintain a cool feeling And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Modified sweetener is made by following steps:

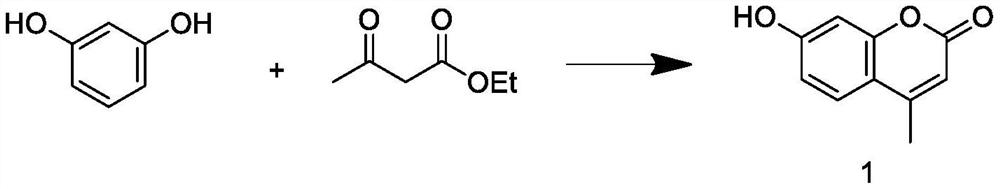

[0041] Step S1, add 21mL perchloric acid and 0.3mol resorcinol to the three-necked flask, stir evenly, add 0.33mol ethyl acetoacetate to it, reflux reaction for 5h, pour the reactant into ice water to precipitate, and use for precipitation 5% sodium hydroxide solution was dissolved, then 5% hydrochloric acid solution was added dropwise to precipitate again, the crude product was obtained by vacuum filtration, and then recrystallized with absolute ethanol to obtain intermediate 1;

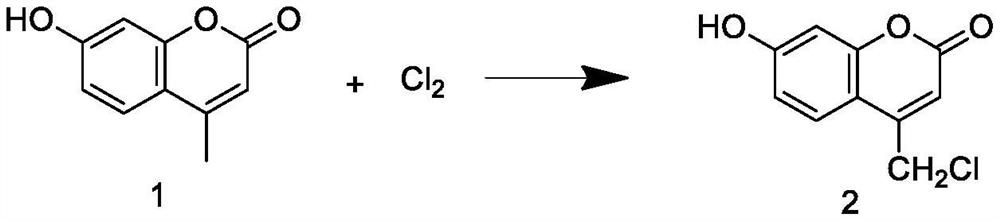

[0042] Step S2, dissolving 0.2 mol of intermediate 1 in 15.5 mL of tetrahydrofuran, and reacting with 0.1 mol of chlorine gas under light conditions for 1 h to prepare intermediate 2;

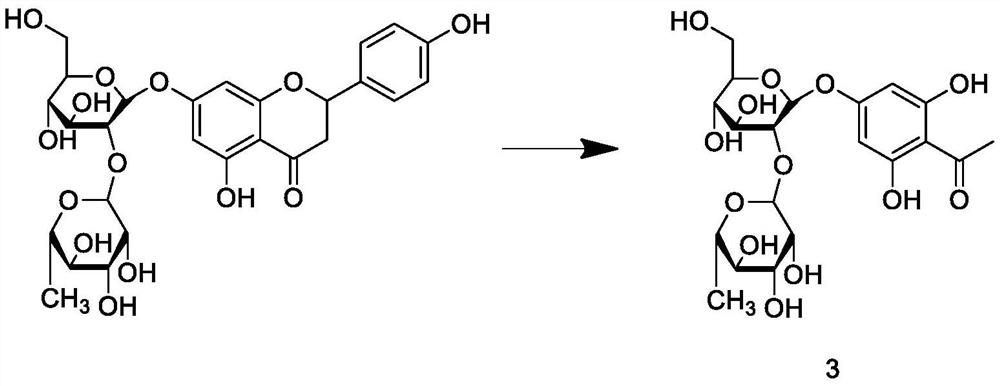

[0043] Step S3, add 8.2mmol of naringin and 62mL of KOH solution with a mass fraction of 16% to the three-necked flask, stir and dissolve, heat to 75°C for 3 hours, adjust the pH to 5.5 with a 36% hydrochloric acid solution, and pump under reduced pressure filt...

Embodiment 2

[0048] Modified sweetener is made by following steps:

[0049] Step S1, add 22mL perchloric acid and 0.3mol resorcinol to the three-neck flask, stir evenly, add 0.33mol ethyl acetoacetate to it, reflux reaction for 5h, pour the reactant into ice water to precipitate out, use for precipitation 5% sodium hydroxide solution was dissolved, then 5% hydrochloric acid solution was added dropwise to precipitate again, the crude product was obtained by vacuum filtration, and then recrystallized with absolute ethanol to obtain intermediate 1;

[0050] Step S2, dissolving 0.2 mol of intermediate 1 in 15.8 mL of tetrahydrofuran, and reacting with 0.1 mol of chlorine gas under light conditions for 1 h to prepare intermediate 2;

[0051] Step S3, add 8.4mmol of naringin and 64mL of KOH solution with a mass fraction of 16% to the three-necked flask, stir and dissolve, heat to 75°C for 3 hours, adjust the pH to 6 with a 36% hydrochloric acid solution, and pump under reduced pressure filtered...

Embodiment 3

[0056] Modified sweetener is made by following steps:

[0057] Step S1, add 23mL perchloric acid and 0.3mol resorcinol to the three-neck flask, stir evenly, add 0.33mol ethyl acetoacetate to it, reflux reaction for 6h, pour the reactant into ice water to precipitate, and use for precipitation 5% sodium hydroxide solution was dissolved, then 5% hydrochloric acid solution was added dropwise to precipitate again, the crude product was obtained by vacuum filtration, and then recrystallized with absolute ethanol to obtain intermediate 1;

[0058] Step S2, dissolving 0.2 mol of intermediate 1 in 16.2 mL of tetrahydrofuran, and reacting with 0.1 mol of chlorine gas under light conditions for 1.5 h to obtain intermediate 2;

[0059] Step S3, add 8.5mmol of naringin and 66mL of KOH solution with a mass fraction of 16% to the three-necked flask, stir and dissolve, heat to 75°C for 4 hours, adjust the pH to 6.5 with a 36% hydrochloric acid solution, and pump under reduced pressure Filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com