Automatic fly maggot breeding system and method used in field of organic waste treatment

A technology of organic waste and automatic breeding, which is applied in the direction of solid waste removal, liquid treatment, conveyor objects, etc., and can solve the problems of relying on manual operation, difficulty in screening adults, and hindering the expansion of breeding scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

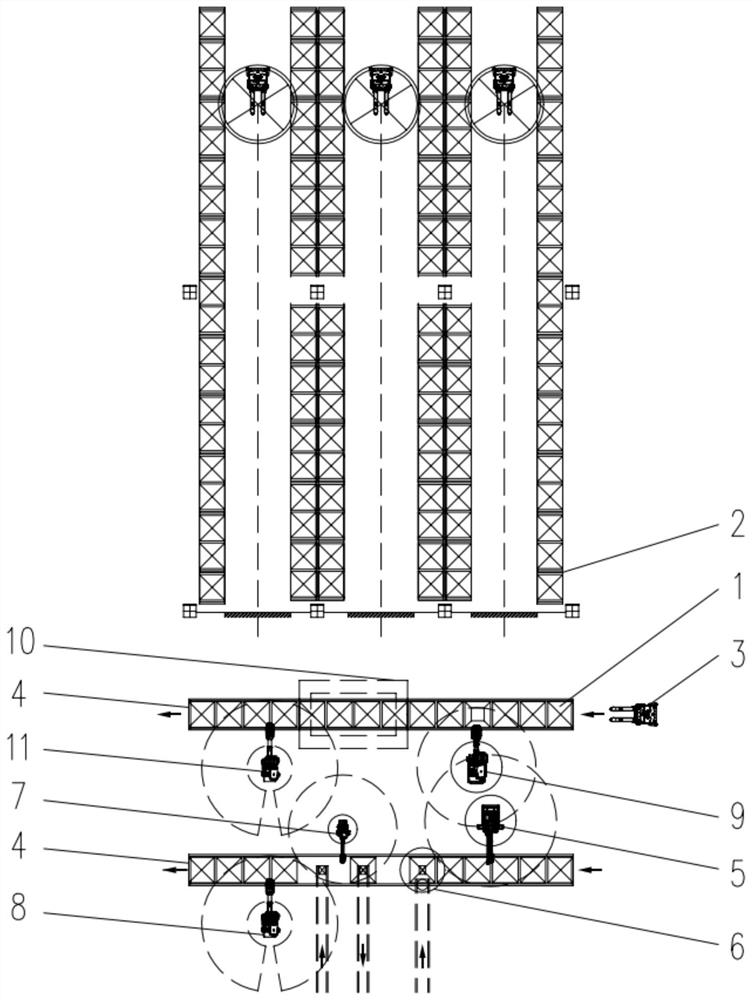

[0029] Embodiment 1 of the present application provides a method such as figure 1 The fly maggot automatic breeding system used in the field of organic waste treatment shown includes: fly maggot storage system, conveying system, distributing system and unloading system; fly maggot storage system includes a breeding box 1 and a breeding rack 2, and the breeding rack 2 is placed Breeding box 1; the conveying system includes an AGV logistics robot 3 and a belt conveying device 4, the AGV logistics robot 3 is a mobile pick-up device, and the belt conveying device 4 is a transmission and transportation device; Insect mechanical arm 7 and a stacking mechanical arm 8, the distributing device 6 is connected to the end of the working area of the unstacking mechanical arm 5 on the belt conveying equipment 4, and the outlet end of the distributing device 6 is connected to the insect adding mechanical arm 7. 4 The end of the working area of the upper worm loading robot arm 7 is connec...

Embodiment 2

[0031] On the basis of Embodiment 1, Embodiment 2 of the present application provides the specific working method of the fly maggot automatic breeding system used in the field of organic waste treatment in Embodiment 1:

[0032] Step 1. The AGV logistics robot 3 transports a stack of empty breeding boxes 1 to the entrance of the fabric system, and the destacking robot arm 5 sequentially grabs the breeding boxes 1 and puts them on the belt conveyor 4 to complete the disassembly of the stacked empty breeding boxes 1; It takes 5-30 seconds to disassemble a single empty breeding box 1;

[0033] Step 2. After step 1, the breeding box 1 is moved to the material distribution port of the distribution system in turn, and the valve is controlled by the material distribution device 6 to feed quantitatively and evenly; the feeding time of a single breeding box 1 takes 10 to 40 seconds;

[0034] Step 3. After step 2, the breeding box 1 is moved to the insect feeding port of the distributin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com