Reaction device convenient for total thermal cracking of solid wastes

A reaction device, solid waste technology, applied in lighting and heating equipment, special forms of dry distillation, combustion methods, etc., can solve problems such as increasing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

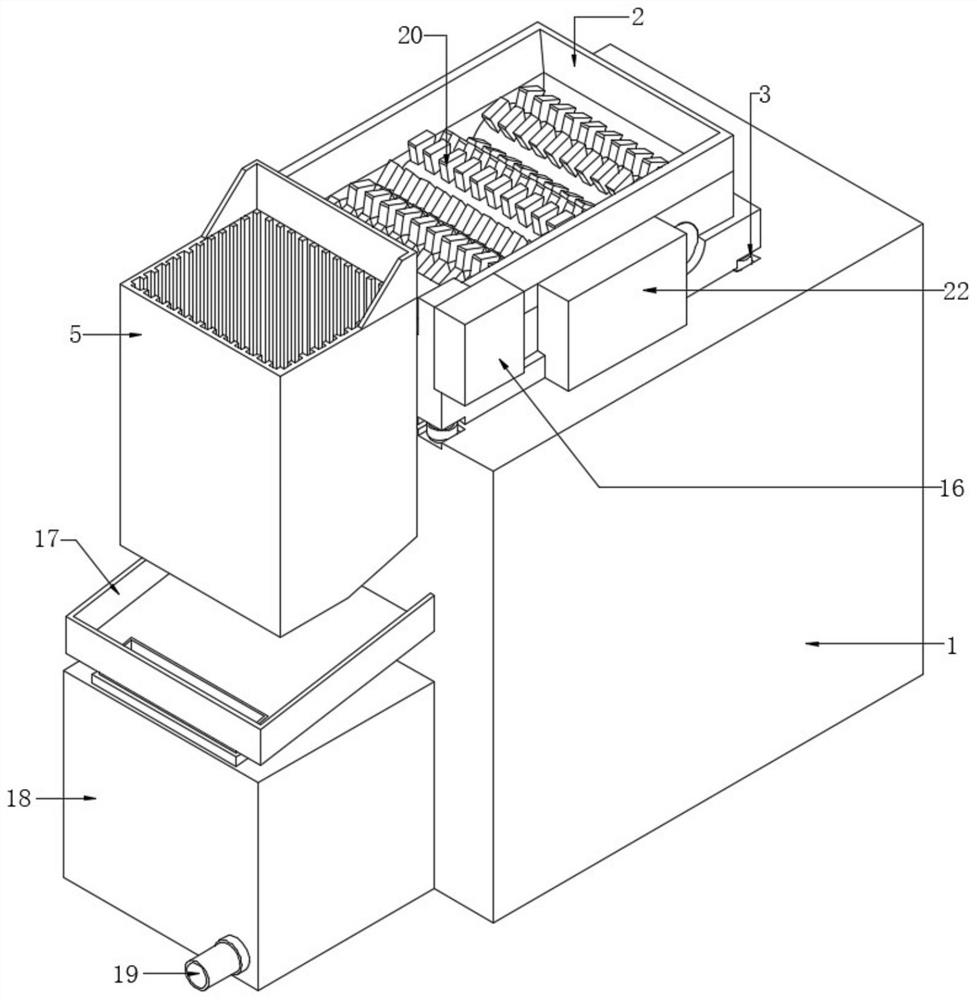

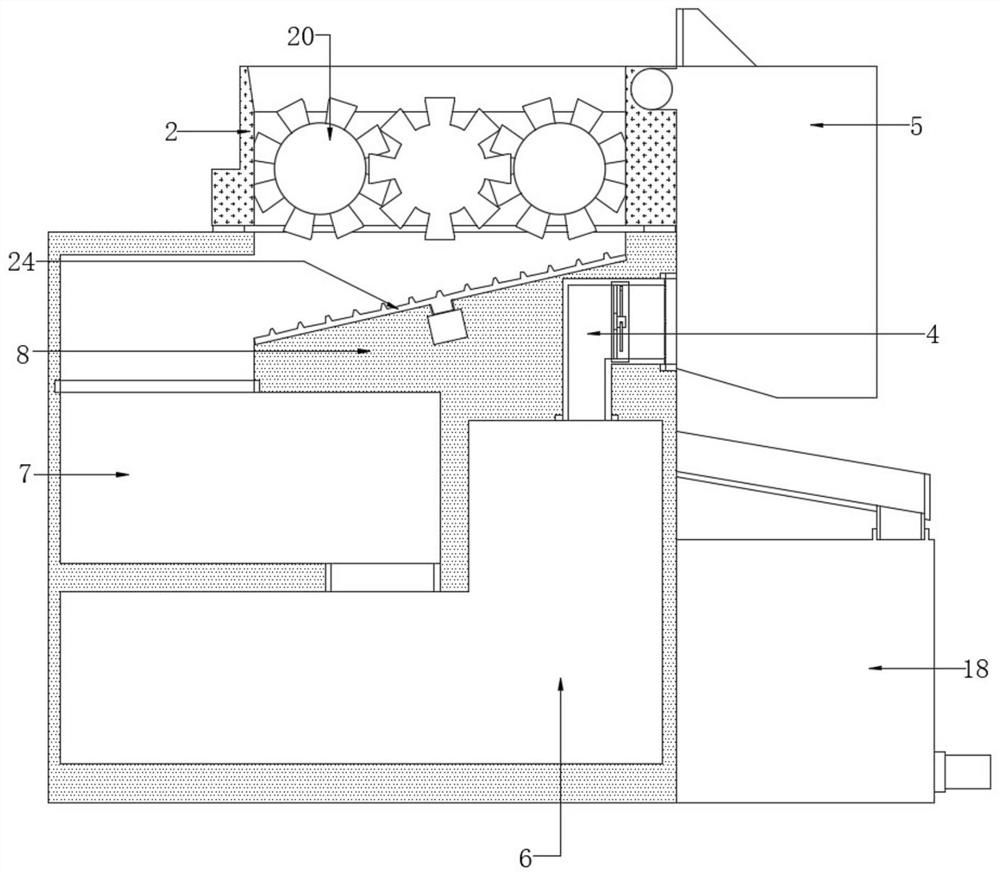

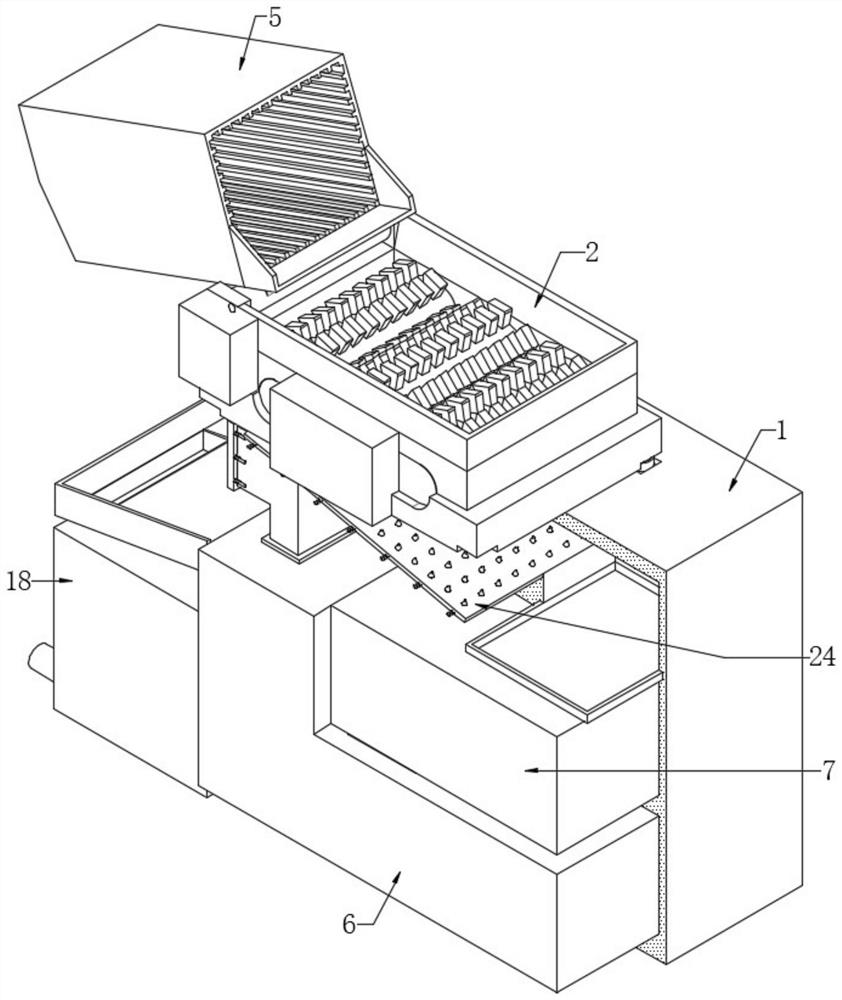

[0030] refer to Figure 1-6 , a reaction device for total thermal cracking of solid waste, comprising a treatment box 1, a crushing box 2 is arranged above the treatment box 1, and the lower outer wall of the crushing box 2 and the upper outer wall of the treatment box 1 are connected by bolts There is a damper 3, the inside of the processing box 1 is provided with an exhaust pipe 4, the inside of the exhaust pipe 4 is provided with an exhaust assembly, and one side of the exhaust pipe 4 is provided with a charging box 5, and the inside of the charging box 5 is provided with As for the drying assembly, an incineration box 6 is arranged inside the treatment box 1 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com