Automobile air filter

An air filter, automobile technology, applied in the direction of fuel air filter, combustion air/combustion-air treatment, machine/engine, etc., can solve the problem of incomplete fuel combustion, short filter life, low filter efficiency and low flow resistance and other problems to achieve the effect of improving effect and efficiency, prolonging service life and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

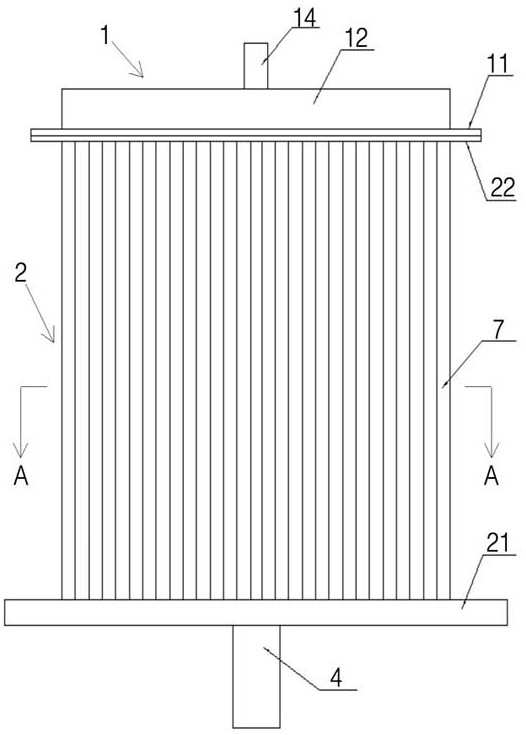

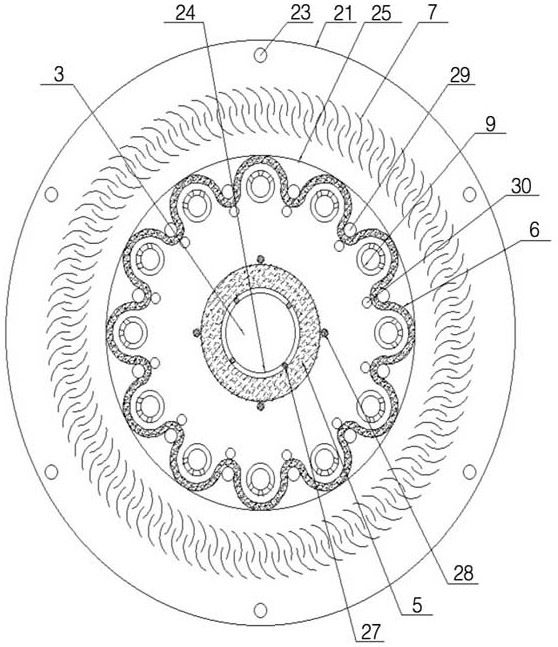

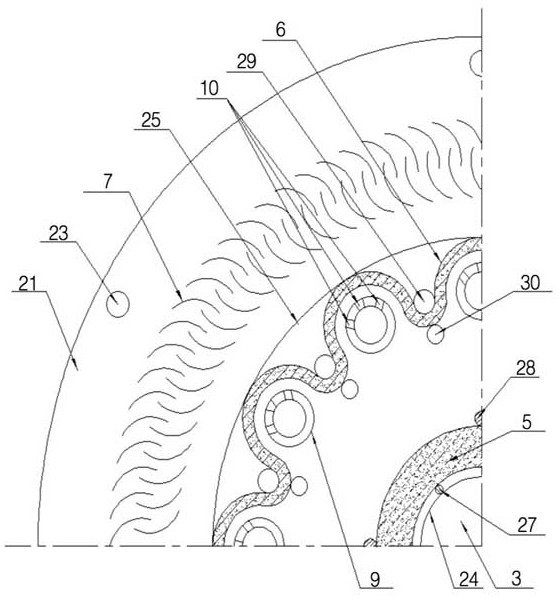

[0027] Such as Figure 1-7 As shown, the present embodiment is an automobile air filter, comprising an upper cover body 1 and a lower casing 2, the lower casing 2 includes a bottom plate 21 and an annular flange 22, and the annular flange 22 is provided with A plurality of installation holes 20, the outer edge of the base plate 21 is provided with a plurality of fixing holes 23 for connecting with external equipment, the center of the base plate 21 is formed with an air outlet 3, and the bottom of the base plate 21 is provided with a corresponding air outlet 3 The air outlet pipe 4 is provided with a cylindrical first filter element 5 at the periphery of the air outlet hole 3 at the top of the bottom plate 21, and a cylindrical second filter element 6 is arranged at the periphery of the first filter element 5 at the top of the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com