A civil engineering building composite pile

A technology of civil engineering and combined piles, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve problems affecting the support stability of combined piles, easy to freeze, and frost heaving of the soil layer, so as to improve protection and save energy. Electricity cost, erosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

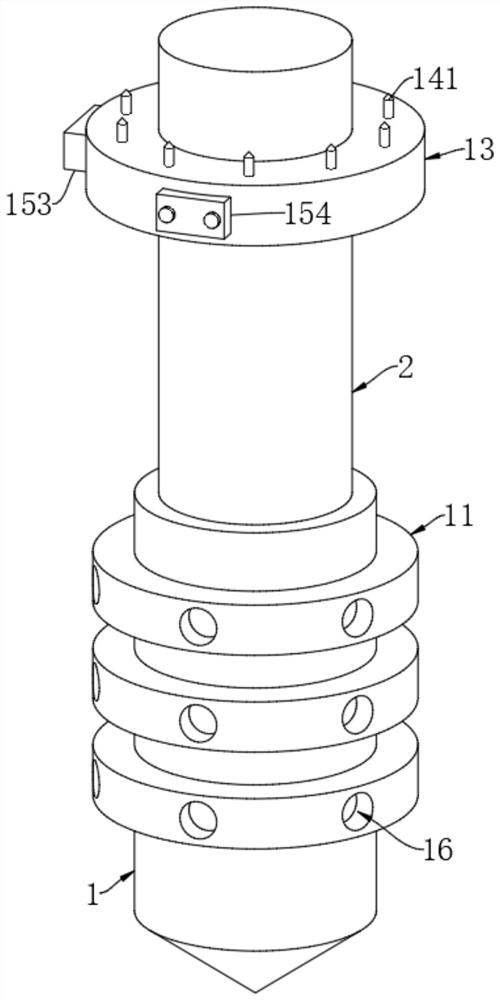

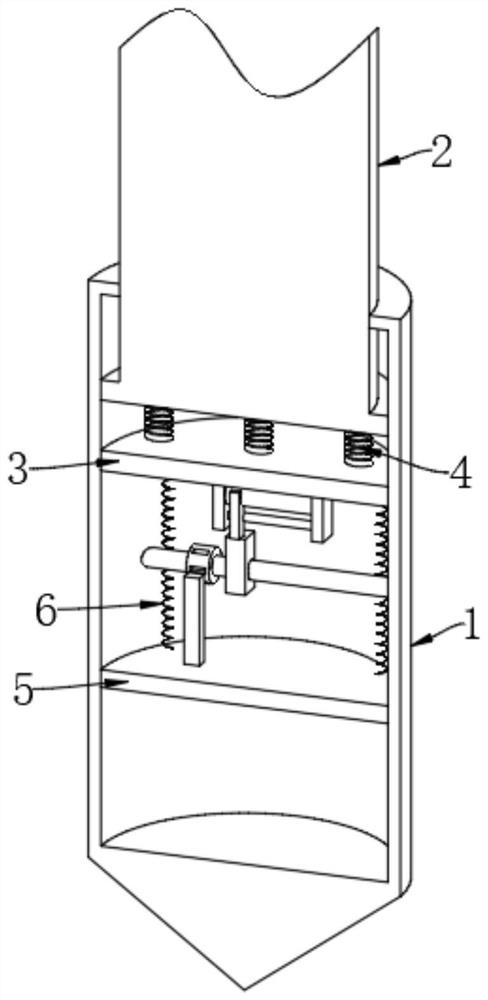

[0023] like Figure 1-6 As shown, a civil engineering construction composite pile includes an insertion pile 1 and a support pile 2, the insertion pile 1 is a hollow design, and the support pile 2 is slidably arranged in the insertion pile 1, and the insertion pile 1 is fixedly connected with a buffer plate 3, A plurality of buffer springs 4 are fixedly connected between the buffer plate 3 and the support pile 2 , and the buffer plate 3 and the buffer spring 4 can provide buffer protection to the support pile 2 .

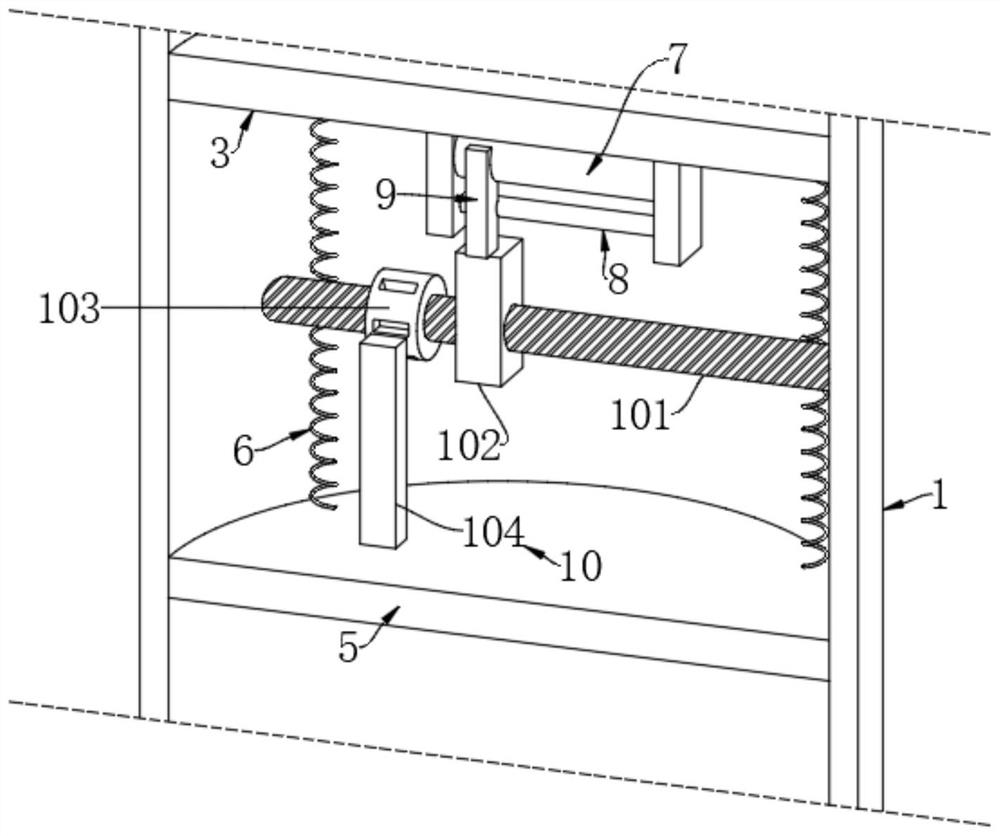

[0024] A partition 5 is slidably connected in the plug 1, and water is injected into the lower side of the partition 5, a plurality of tension springs 6 are fixedly connected between the buffer plate 3 and the partition 5, and a varistor is fixedly connected to the lower end of the buffer plate 3 7, and a metal guide rod 8 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com